Camera control device and camera control method for printing plate quality inspection instrument

A quality inspection and control device technology, applied in the direction of use feedback control, etc., can solve the problems that affect the quality inspection of printing plates, poor shooting effect, etc., and achieve the effect of improving precision and good shooting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

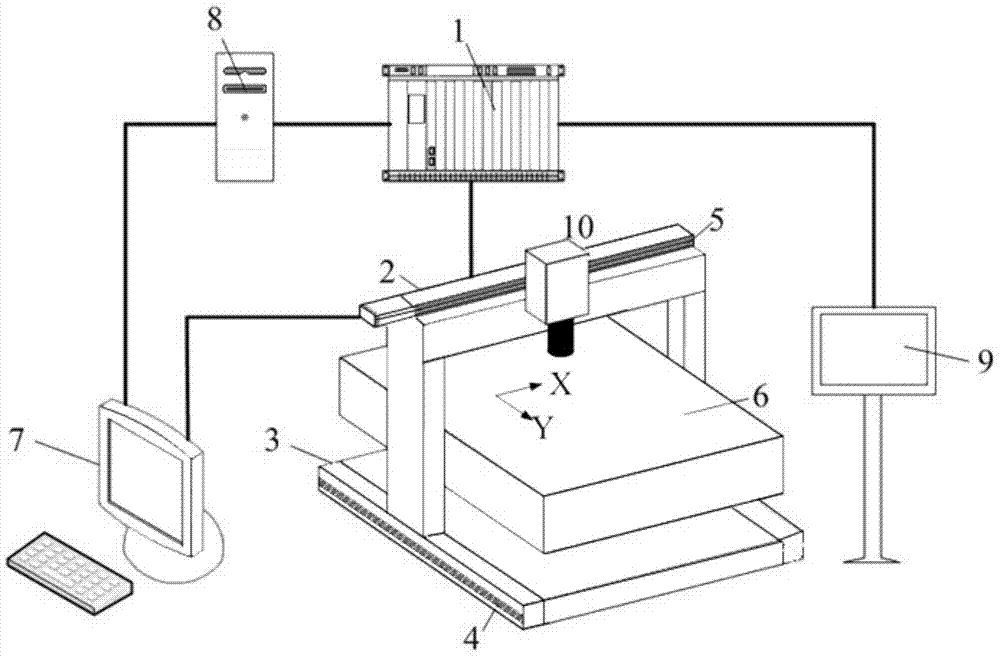

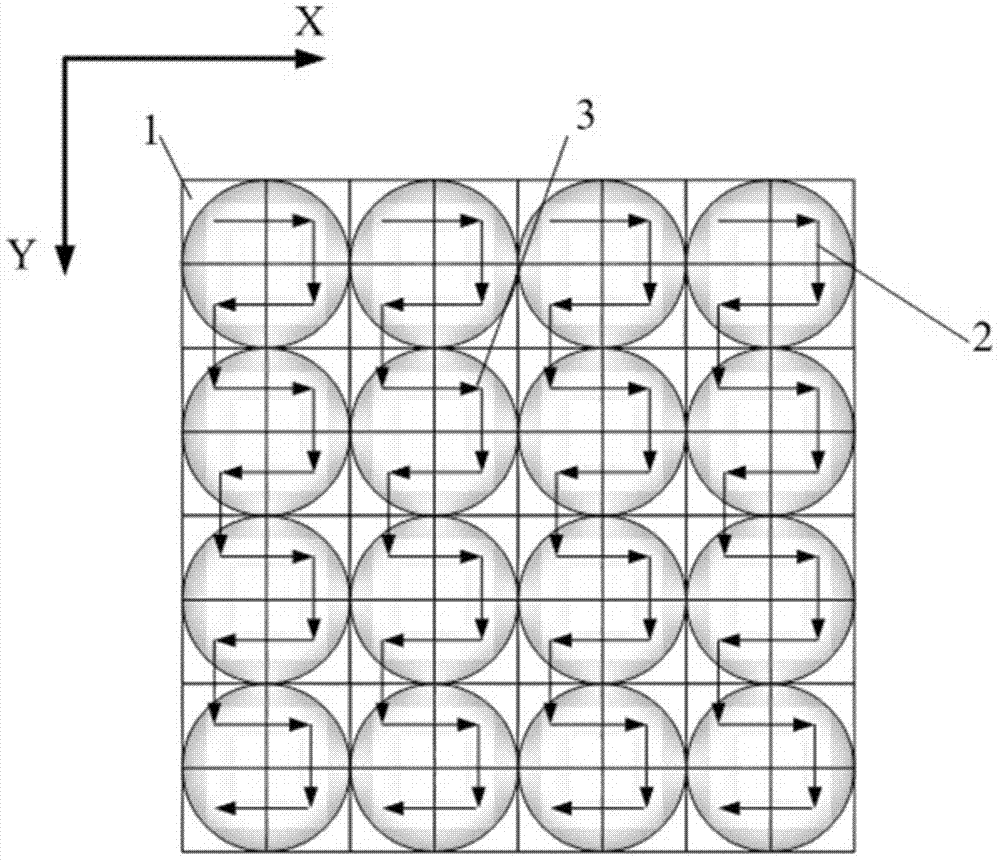

[0020] The camera control device and control method of the printing plate quality inspection instrument provided by the present invention are used for the detection of sample banknote printing plates. After the sample banknote printing plates are placed on the measuring platform 6, they need to take pictures. Under the control of the control device, the sample banknote printing plate is photographed at a fixed distance, and then subsequent operations are performed.

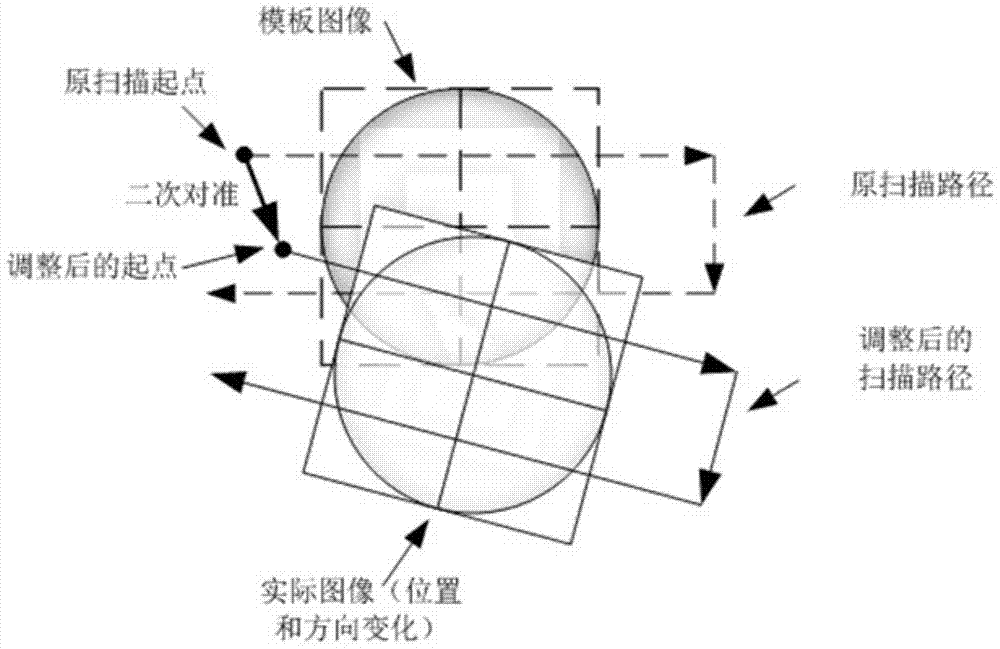

[0021] Such as Figure 1-4 As shown, the camera control device of the printing plate quality inspection instrument includes a control unit, a control terminal, a camera motion control module and a camera position detection module.

[0022] The control unit is used to control the operation of the camera control device, including a computer 11 and a motion controller 1 with a built-in multi-axis control card 7, the multi-axis control card 7 is built in the host computer 11, the The multi-axis control card 7 transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com