A low-center high-capacity motor

A low-center, tall technology, applied in the field of low-center, high-capacity motors, can solve the problems of being unable to adapt to the installation of the adjusted junction box, the effective material length of the motor is limited, and the capacity of the single motor cannot be increased, so as to improve safety and reliability. The effects of reducing processing procedures and man-hours, and facilitating installation and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

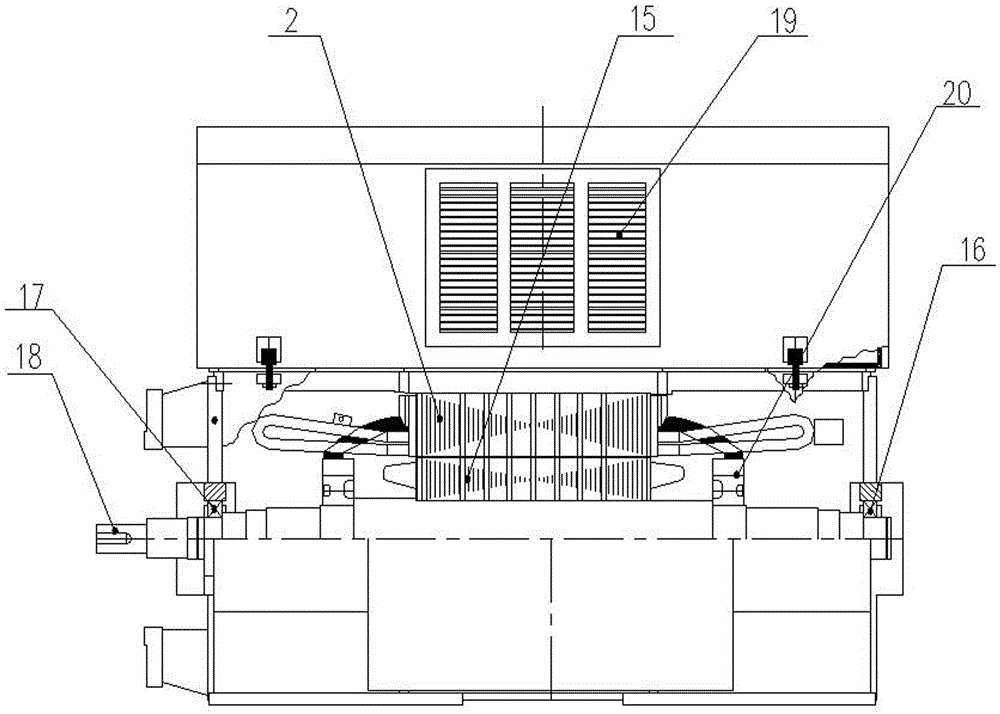

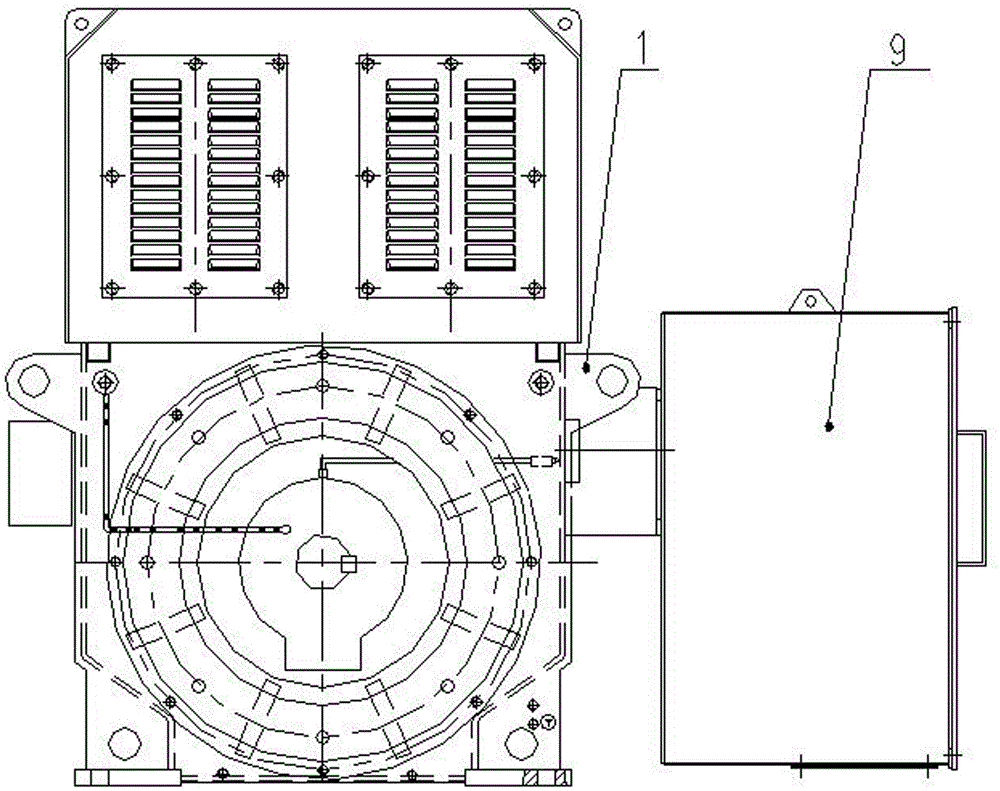

[0028] Such as figure 1 with figure 2 As shown, the present invention includes a machine base 1, a cast aluminum rotor 15 and a stator core 2 arranged in the machine base 1, a winding coil 5 is arranged on the stator core 2, and a windshield structure is fixedly arranged at the end of the winding coil 5, the machine The base 1 is provided with a junction box 9, the end plates 1-1 at both ends of the machine base 1 are provided with a front rolling bearing 17 and a rear rolling bearing 16, and the two ends of the rotating shaft 18 are connected with the front rolling bearing 17 and the rear rolling bearing 16, and the rotating shaft 18 A symmetrically installed axial flow fan 20 is provided, and a top cover 19 is provided above the machine base 1, and the top cover 19 is used for natural cooling wind to enter and exit.

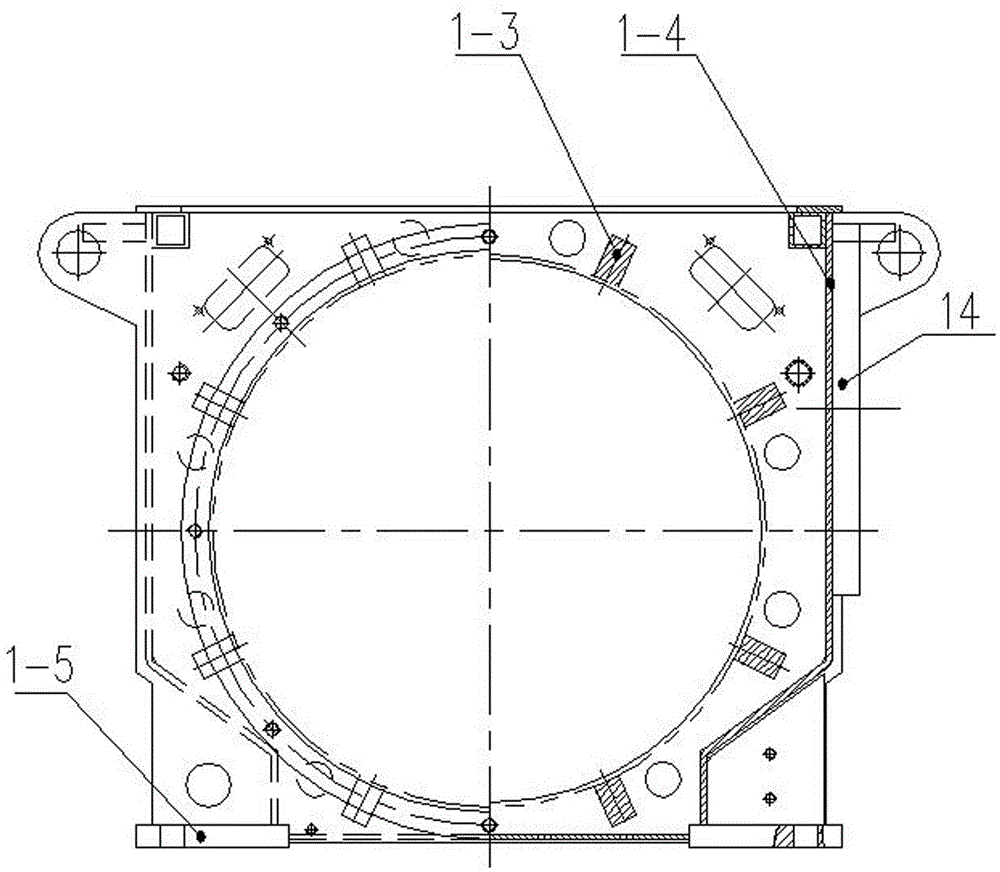

[0029] Such as image 3 As shown, the wind-shielding structure includes a wind-shielding ring 4 that is coaxial with the outer diameter of the stator core 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com