Processing method of automatic water diversion device for continuous casting secondary cooling water spray bar base pipe

A technology of shower strip base pipe and water separation device, applied in the field of cast steel, can solve the problems of irregular position and shape of liquid core area, unimproved center segregation of casting billet, uneven cooling of casting billet, etc., so as to save cost. process, improve the accuracy of water distribution control, and reduce the frequency of replacing spray bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

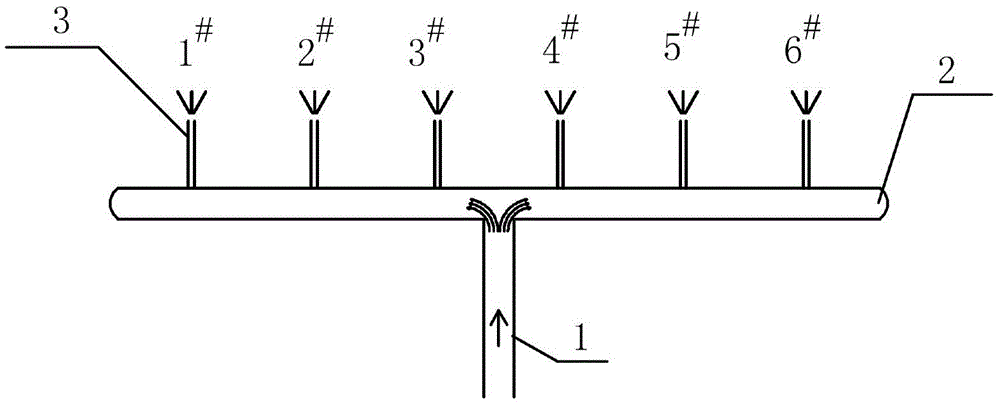

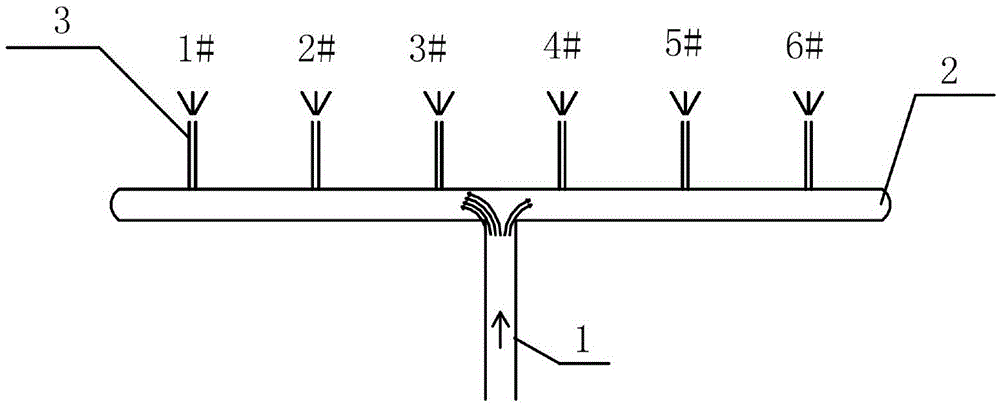

[0032] Such as Figure 5 Shown is a schematic structural view of the continuous casting secondary cooling water water device in the present invention. The structure of the continuous casting secondary cooling water spray bar base pipe water diversion device includes: the main pipe 1, the base pipe 2, the spray bar 3 and the water diversion block 51; the main pipe 1 is connected to the middle of the base pipe 2, and the spray The strips 3 are evenly distributed and connected to the base pipe 2; the water diversion baffle 51 is arranged inside the base pipe 2 and located at the junction of the main pipeline 1 and the base pipe 2.

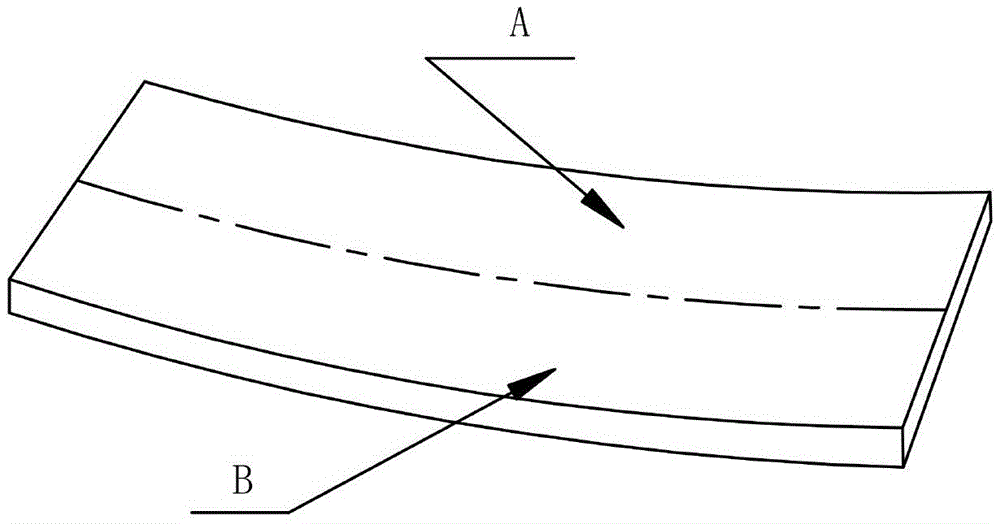

[0033] In this preferred embodiment, at the A place of the base pipe 2 corresponding to the axis of the main pipeline 1, use a pipe cutter to open, and use a circular water diversion block a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com