A kind of nano-silver inorganic antibacterial master batch for highly transparent polyolefin plastics and its preparation method and its application

A technology of antibacterial masterbatch and nano-silver particles, which is applied in the field of plastics and can solve the problems of high cost of nano-silver powder, affecting the transparency of materials, and restricting applications due to migration and precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

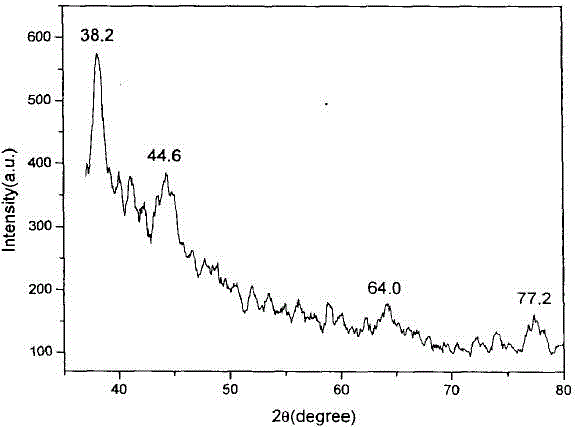

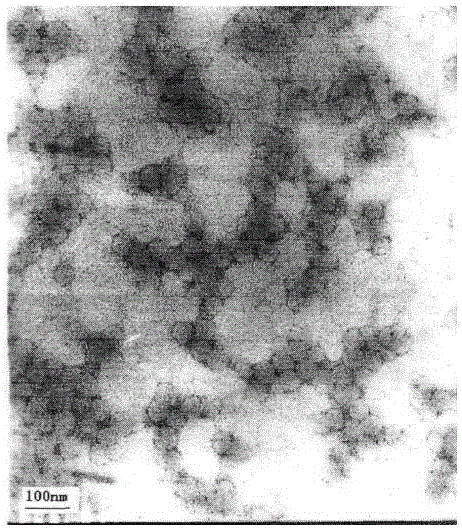

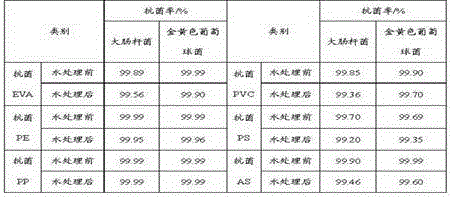

Image

Examples

Embodiment 1

[0079] Embodiment 1: Preparation of nano-silver inorganic antibacterial masterbatch for polyolefin of the present invention

[0080] Step A: Add 2 parts by weight of silver acetate and 98 parts by weight of ethanol to a stainless steel reaction kettle produced by Weihai Chemical Machinery Co., Ltd., and stir for 80 minutes at a temperature of 35°C to completely dissolve the silver acetate in the solvent In, a homogeneous and transparent solution was obtained;

[0081] Step B: Add 10 parts by weight of the homogeneous transparent solution obtained in step A, 100 parts by weight of highly transparent EVA (28 / 25) resin, 2 parts by weight of PVP (K30) and 0.5 parts by weight of AClyn291A to Zhangjiagang Chuangjia Machinery Co., Ltd. In the high-speed mixer produced, the high-speed mixing and stirring treatment was carried out at a temperature of 60°C for 40 minutes, and at the same time, about 90% of the excess solvent was dried and recovered;

[0082] Step C): Put the fully mixe...

Embodiment 2

[0084] Embodiment 2: Preparation of nano-silver inorganic antibacterial masterbatch for polyolefin of the present invention

[0085] Step A: Add 1 part by weight of silver nitrate and 99 parts by weight of methanol into a glass-lined reaction kettle produced by Wuxi Suyang Chemical Equipment Co., Ltd., and stir for 180 minutes at a temperature of 60° C. to completely dissolve the silver nitrate in the In the solvent, a homogeneous and transparent solution was obtained;

[0086] Step B: Add 20 parts by weight of the homogeneous transparent solution obtained in step A, 93 parts by weight of highly transparent poly LDPE (1C7A) resin, 1 part by weight of PEG200 and 1 part by weight of AClyn295A into the high-speed machine produced by Zhangjiagang Chuangjia Machinery Co., Ltd. In the mixer, carry out high-speed mixing and stirring treatment at a temperature of 60°C for 60 minutes, and at the same time dry out and recover about 90% of the excess solvent;

[0087] Step C): Put the f...

Embodiment 3

[0089] Embodiment 3: Preparation of nano-silver inorganic antibacterial masterbatch for polyolefin of the present invention

[0090] Step A: Add 3 parts by weight of silver nitrate and 97 parts by weight of ethanol to the glass-lined reaction kettle produced by Weihai Chemical Machinery Co., Ltd., and stir for 70 minutes at a temperature of 50°C to completely dissolve the silver nitrate salt. In the solvent, a uniform and transparent solution is obtained;

[0091] Step B: Add 10 parts by weight of the homogeneous transparent solution obtained in step A, 95 parts by weight of highly transparent PP (RJ580), 5 parts by weight of PEG2000 and 2.0 parts by weight of AClyn201A into a high-speed mixer produced by Zhangjiagang Chuangjia Machinery Co., Ltd. , at a temperature of 75°C, carry out high-speed mixing and stirring treatment for 45 minutes, and at the same time dry and recover about 90% of the excess solvent;

[0092] Step C): Put the fully mixed and processed materials in St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap