Oblique crossing normal reinforcing 2.5D fabric and weaving method thereof

A technology of fabric and fabric thickness, applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve the problems of not meeting the mechanical performance requirements of components, and achieve the effect of shear performance between high layers, strong operability, and enhanced integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

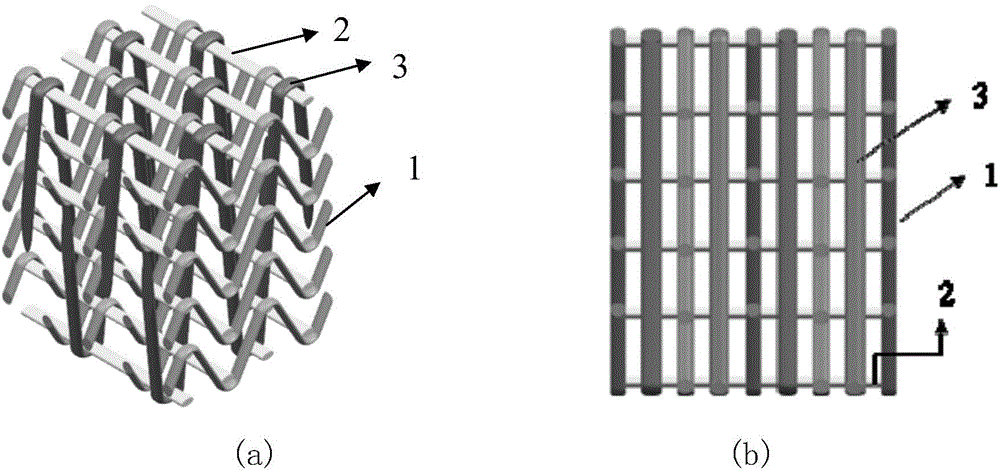

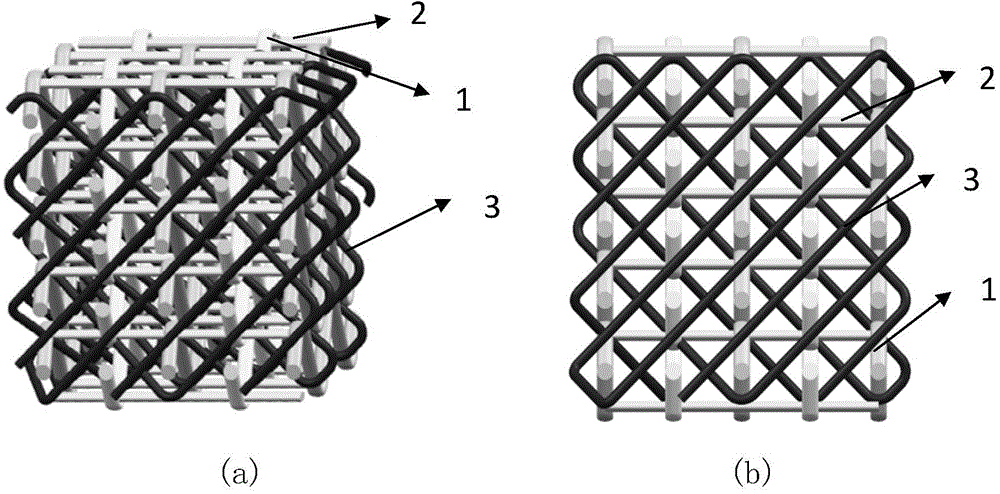

[0049] Design a bias normal reinforced 2.5D fabric (see figure 2 ). The fabric adopts the angle interlocking structure of diagonal normal reinforced layers, including 5 layers of warp yarn 1 and 6 layers of weft yarn 2;

[0050] The number of wefts required for the normal yarn to complete one interweaving cycle: 2 wefts.

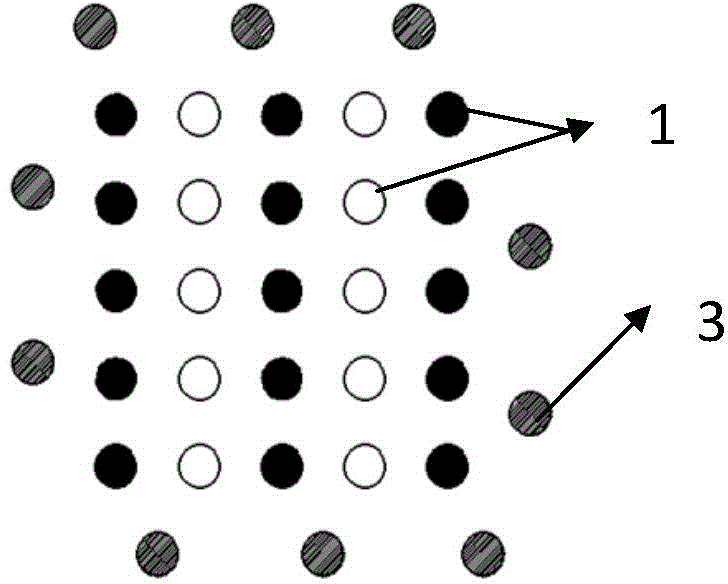

[0051] 1) Initial yarn arrangement. The warp yarns are arranged in 5 layers, and 5 layers and 5 columns are selected for illustration (see Figure 5 ), ○ stands for warp yarns in odd columns, ● stands for warp yarns in even columns, ①-⑧ stands for normal yarns. Wherein the warp thread of ○ representative penetrates in a heald frame 4, the warp thread of ● representative penetrates in another heald frame 5, and the normal direction yarn of ①-⑧ representative penetrates on the yarn carrying device arranged around.

[0052] 2) The first warp shedding movement. The heald raising device controls a heald frame 4 to move up the position of a warp yarn, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com