Assembled concrete seismic beam-column frame and construction method thereof

A concrete and prefabricated technology, applied in earthquake resistance, building components, buildings, etc., can solve the problems of poor integrity, transportation and installation, hinder and restrict the popularization and application of prefabricated reinforced concrete structures, achieve good integrity, be conducive to shear bearing, Easy to assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, invention is further described:

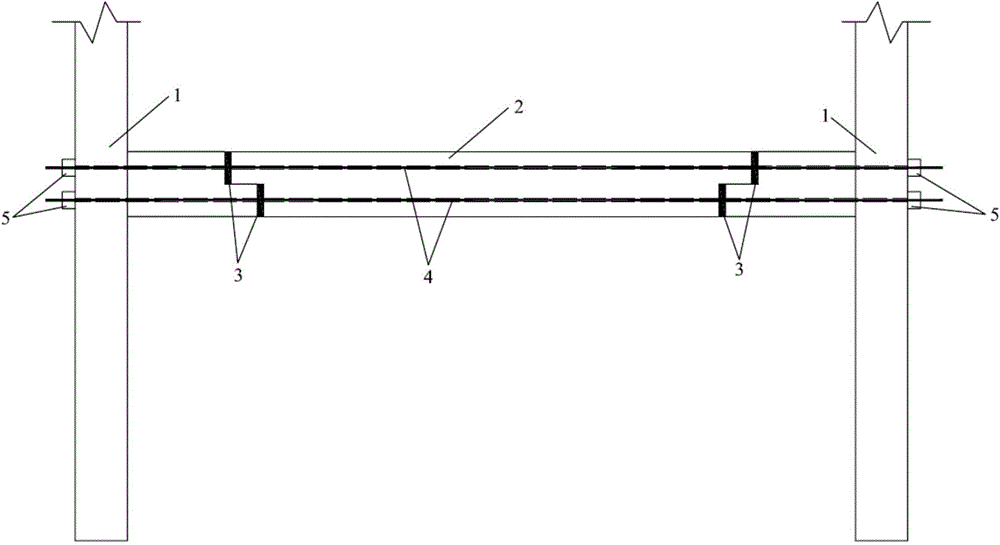

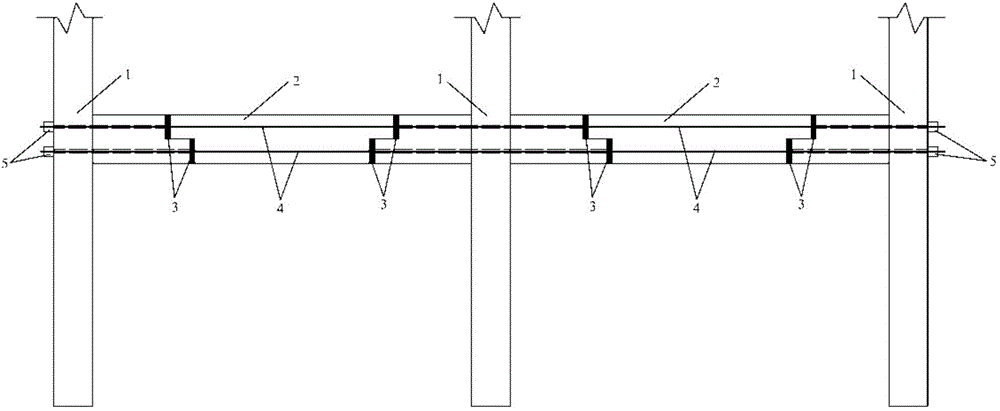

[0029] Fig. 1 is a schematic diagram of the present invention

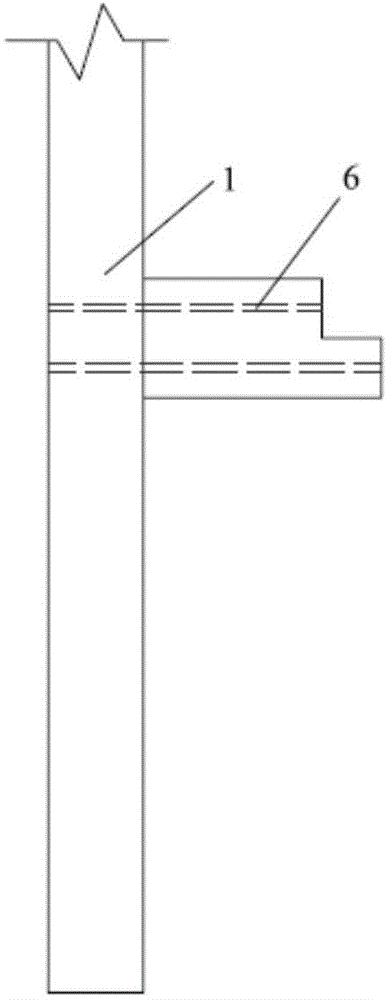

[0030] A prefabricated concrete anti-seismic beam-column frame, comprising a corbel 1, a beam 2, a steel strand 4 and an anchor 5, the beam 2 is arranged between two corbels 1, and the interior of the beam 2 is arranged along the transverse direction There are through holes, the cantilevered part of the corbel column 1 and the column body are provided with horizontal through holes corresponding to the beam 2, the steel strand 4 passes through the through holes in the corbel column 1 and the beam 2 in turn, and anchors are used to 5. Fix the steel strand 4 on the corbels 1 at both ends, which is characterized in that: the upper part of the cantilevered part of the corbel 1 is shorter than the bottom, and the end face is in a two-step shape, and the crossbeam 2 and the corbel 1 are suspended The end faces connected by the pick ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com