Rotary drum dryer

A dryer and drum technology, applied in dryers, drying, non-progressive dryers, etc., can solve the problems of poor drying effect and high energy consumption, and achieve the effects of reducing energy consumption and reducing wind speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

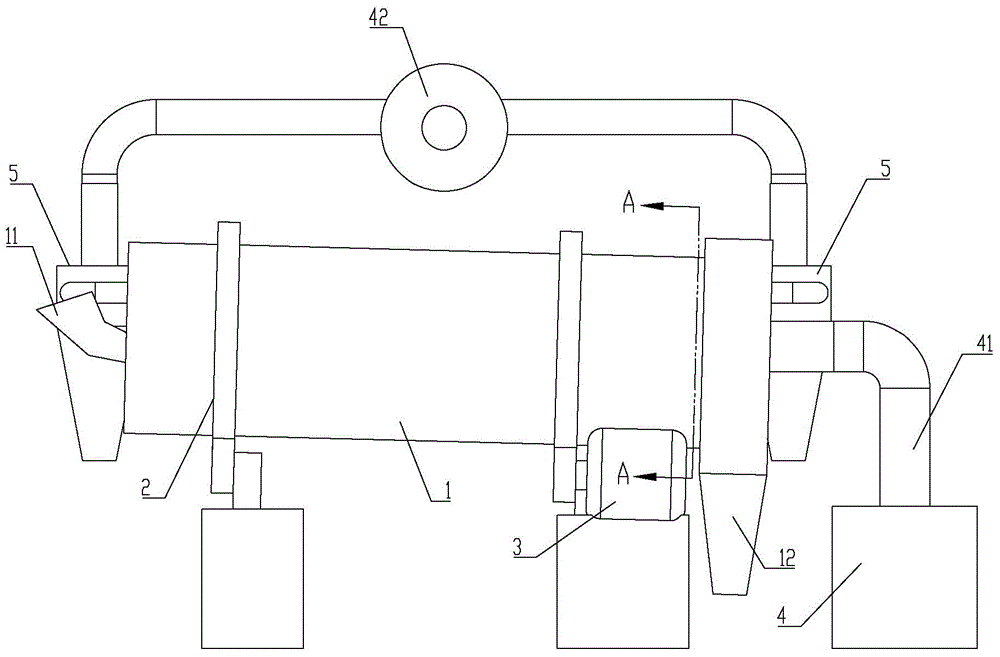

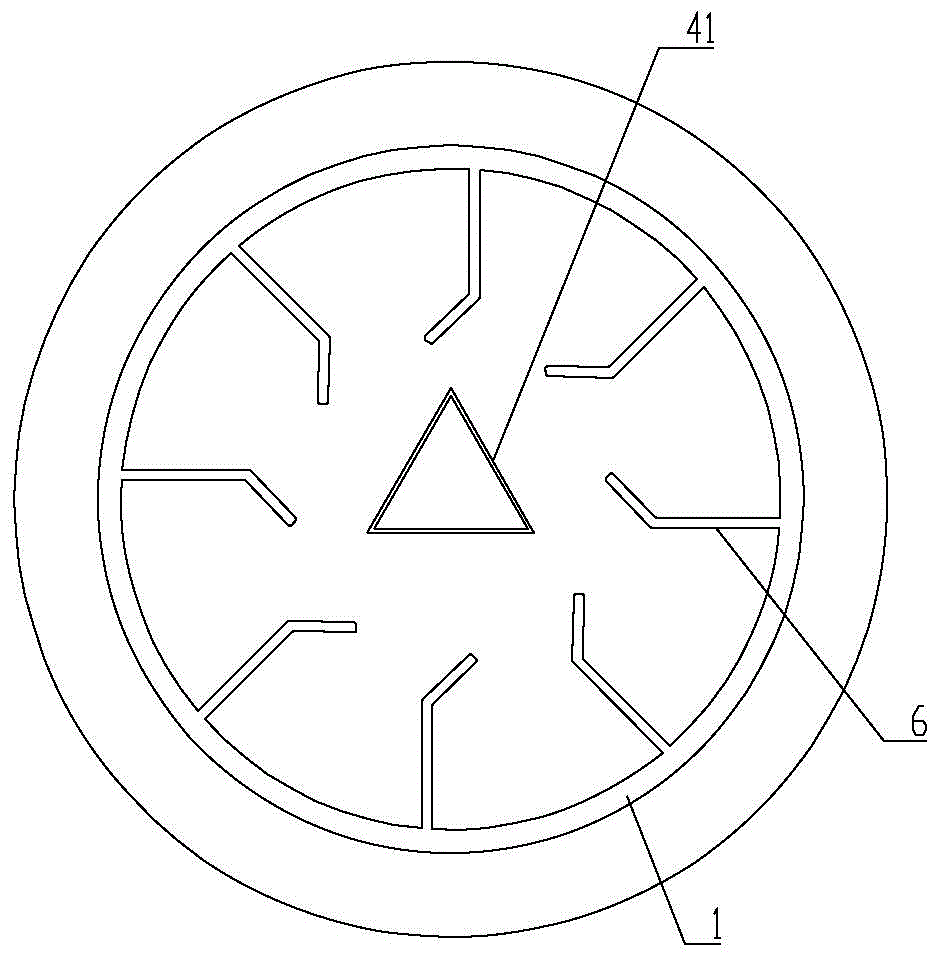

[0018] The present invention will be described in detail below with reference to the drawings, such as figure 1 with 2 Shown: the tumble dryer of this embodiment includes a cylindrical body 1 that is slightly inclined to the horizontal plane, a bracket part 2 that supports the entire body so that it can rotate, and a transmission part 3 that drives the body 1 to rotate. The structure of the bracket part 2 and the transmission part 3 can adopt the existing technology. One end of the body 1 has a feeding port 11, the other end is provided with a discharge port 12, and the inner wall of the body 1 is provided with a copy board 6; A hot blast stove 4 for delivering hot air into the machine body 1. The hot blast stove 4 is in communication with the inside of the machine body 1 through a blower pipe 41. The blower pipe 41 extends from the lower end of the machine body 1 into the machine body 1 Inside; the hot blast stove 4 uses a variable frequency fan 42 that can control the wind spe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap