Fixed washboard brake performance tester for agricultural machinery

A technology for agricultural machinery and detectors, which is applied to the testing of machinery/structural components, instruments, measuring devices, etc., can solve the problems of large agricultural machinery incapable of power, cumbersome and inconvenient operation, low applicability, etc. Ease of use and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

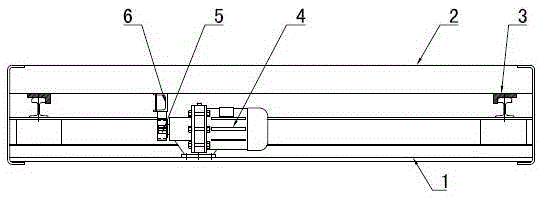

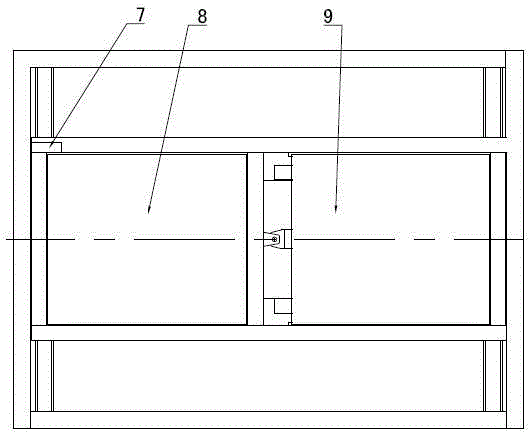

[0015] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~2 The present invention will be further described.

[0016] Refer to attached figure 1 , 2 : Fixed washboard type agricultural machinery brake performance tester, including a fixed washboard body 1 and a washboard inspection table 2 embedded and installed above the fixed washboard body 1, the washboard inspection table 2 consists of a weighing effective plate 8 and a braking effective plate 9 Arrange composition. Four pressure sensors are installed on the four corners of the weighing effective plate 8, and the pressure sensors can detect the gravity of the agricultural machinery to achieve the purpose of weighing. A hydraulic oil cylinder is installed under the brake effective plate 9, and the front end of the hydraulic oil cylinder is connected with an S-shaped pressure sensor. , the wheels are stationary on the brake effective plate 9, when the oil pump is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com