A concrete mixer with automatic water spraying

A technology for concrete mixers and mixing mechanisms, which is applied in cement mixing devices, clay preparation devices, liquid ingredient supply devices, etc. It can solve the problems of difficult mechanical layout, affecting the effect of mixing, and high labor intensity, so as to achieve convenient, accurate and convenient water supply. Clean scraping and high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

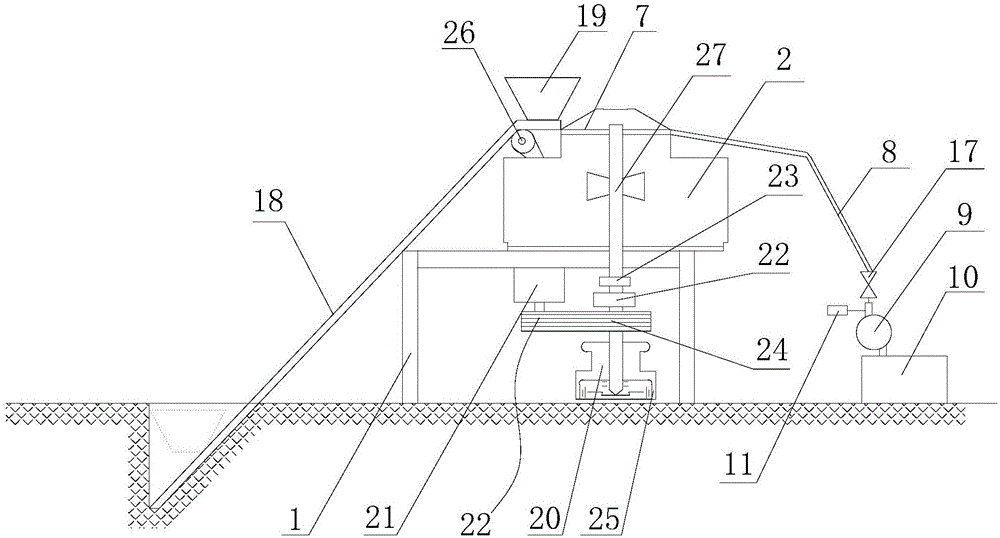

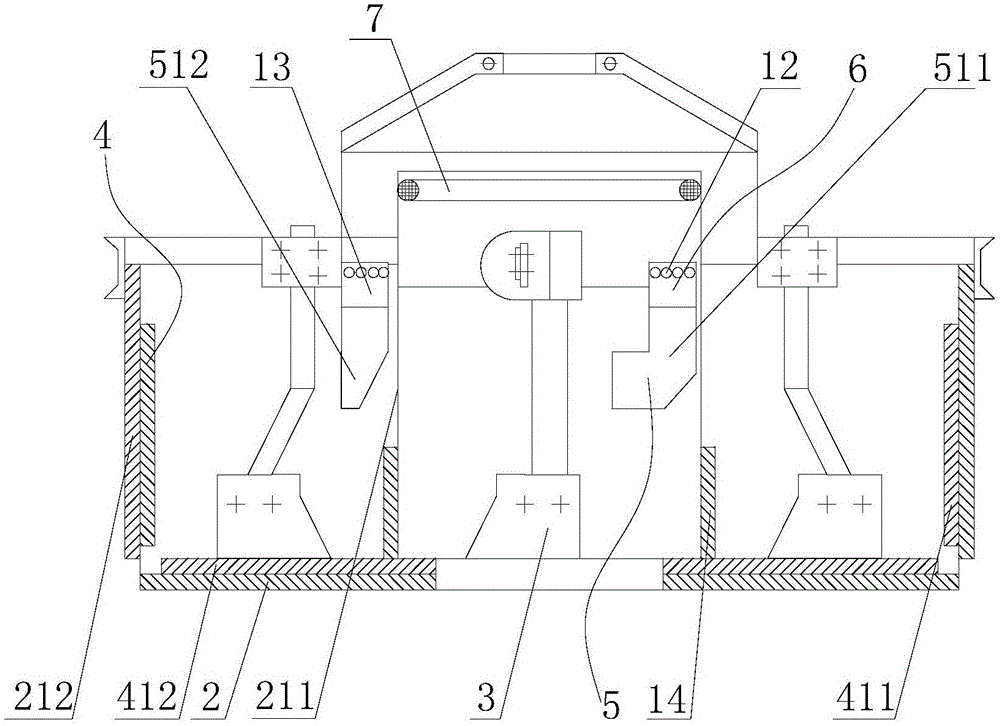

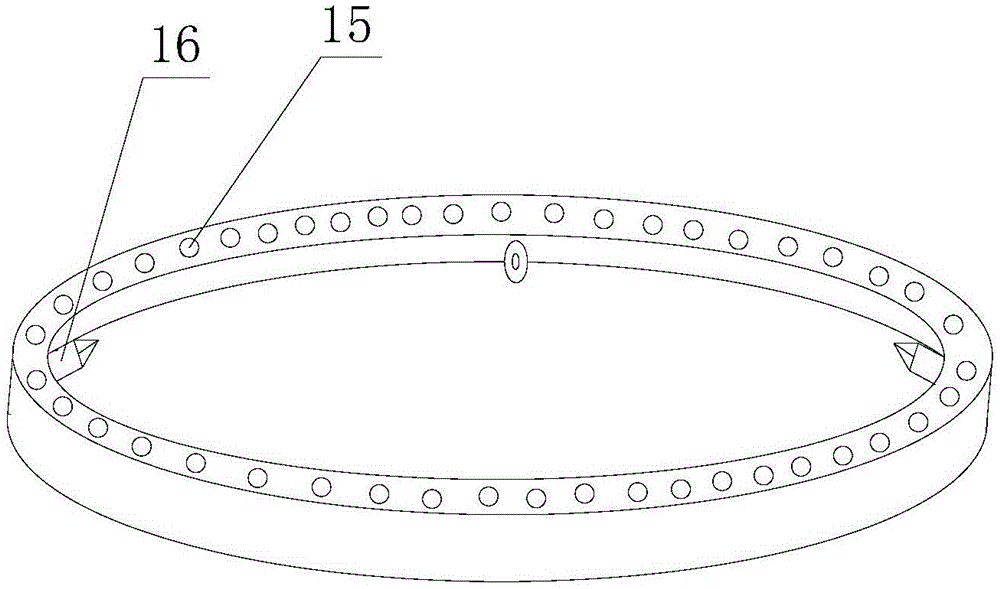

[0020] refer to figure 1 , figure 2 , image 3 , the present invention comprises a frame 1, a stirring mechanism, a feeding mechanism and a driving mechanism, the stirring mechanism is fixed above the frame 1, the driving mechanism is fixed below the frame 1, and the feeding mechanism is fixed on the bottom of the frame 1 On one side, the mixing mechanism includes a mixing drum 2 and a mixing blade 3, the mixing blade 3 is installed in the mixing drum 2, and the inner wall of the mixing drum 2 is provided with a liner 4 and a scraper 5, and the liner 3 and the The mixing drum 1 is screwed and fixed, and there is a gap between the scraper 5 and the inner wall of the mixing drum 2. The scraper 5 is fixed on the mixing drum 2 through the gap adjustment device 6, and the mixing drum 2 is also provided with a water spray pipe 7. The water inlet of the water spray pipe 7 is connected with a water inlet pipe 8, and the water inlet pipe 8 is connected with a water storage tank 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com