Injection molding mechanical hand equipment

A manipulator and equipment technology, applied in the field of injection molding manipulator equipment, can solve problems such as affecting product quality, low work efficiency, and unstable movement, and achieve the effects of stabilizing product quality, improving production efficiency, and reducing scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

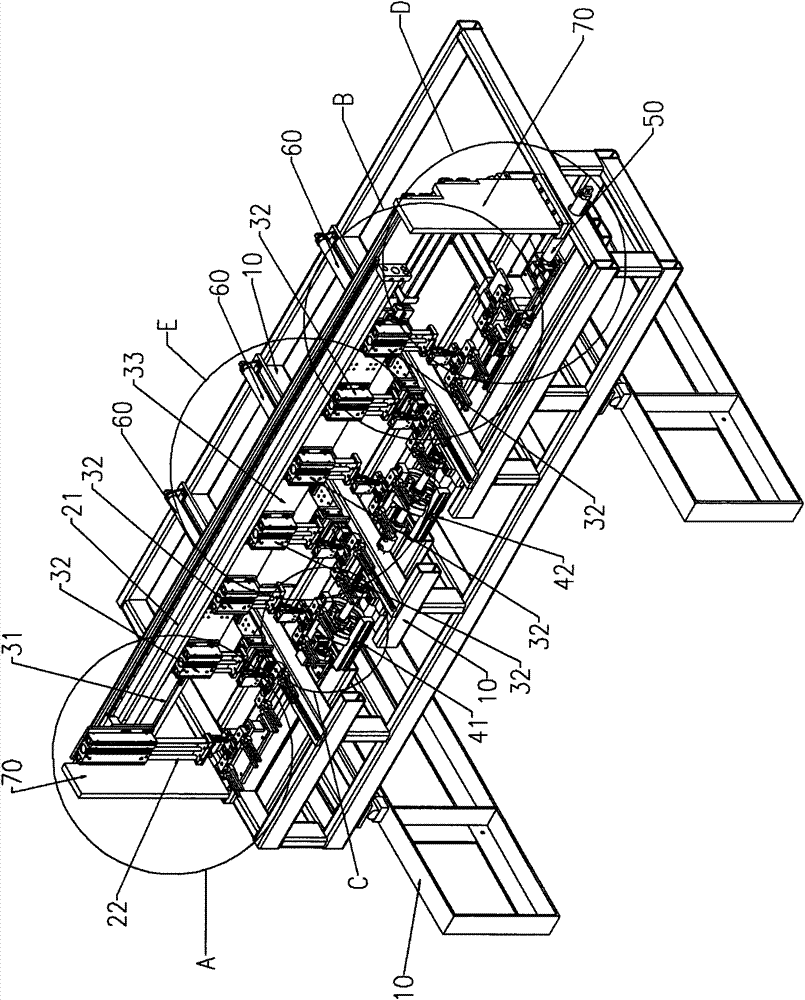

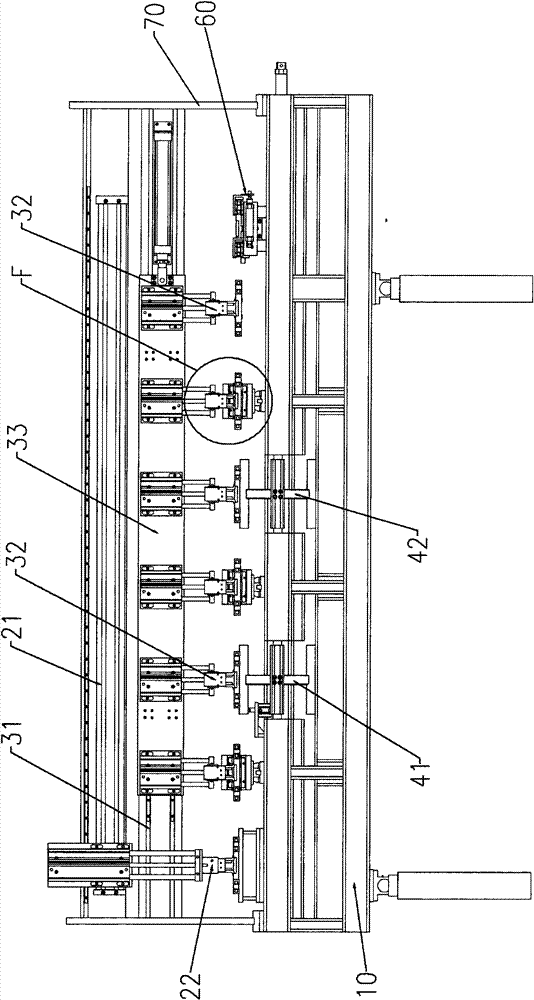

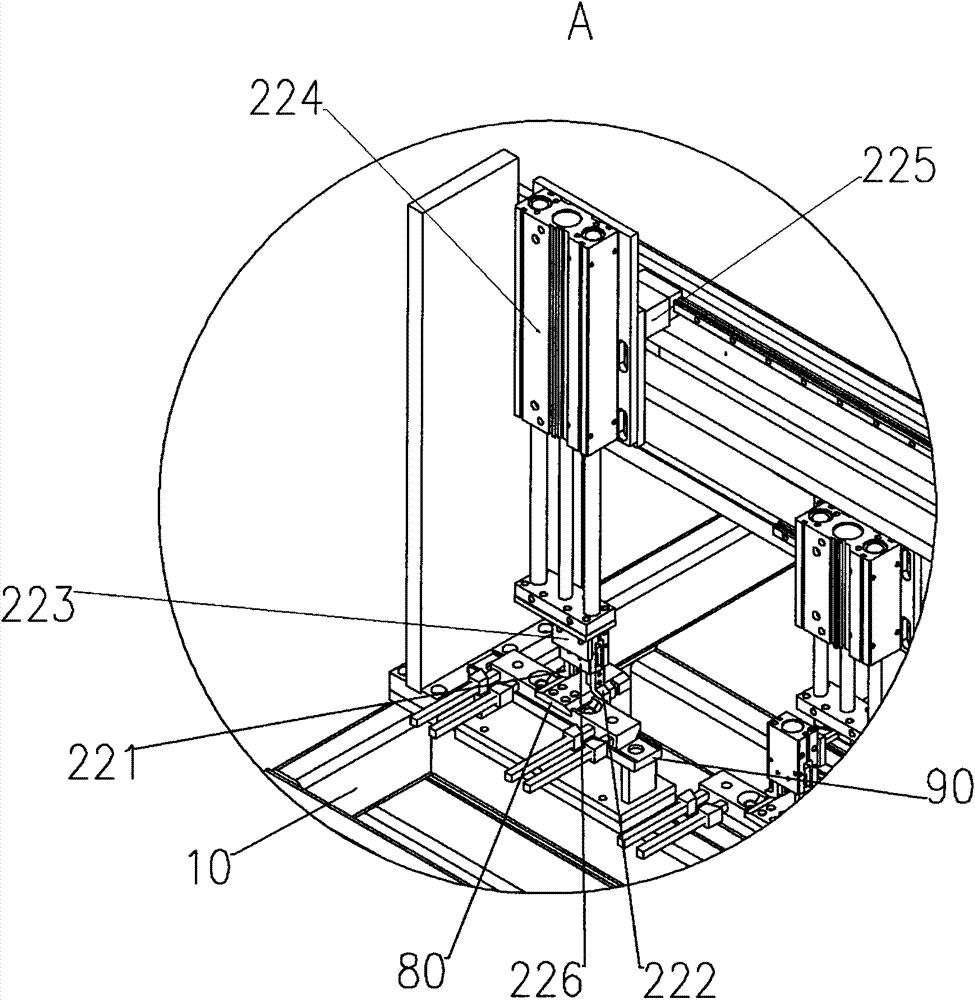

[0028] see figure 1 and figure 2 , the injection molding manipulator equipment of the present embodiment includes a frame 10, a first slide rail 21, a second slide rail 31, a first manipulator device 22, a second manipulator device 32, a first cooling mechanism 41, a second cooling mechanism 42, Push mechanism 60 and demoulding mechanism 50.

[0029] The first manipulator device 22 is arranged on the first slide rail 21;

[0030] The second slide rail 31 is provided with a fixed plate 33 for fixing the second manipulator device 32; the second manipulator device 32 has six, which are fixed on the fixed plate 33 equidistantly in sequence;

[0031] The first cooling mechanism 41 and the second cooling mechanism 42 are sequentially arranged at two positions near the middle of the transverse base of the frame 10;

[0032] There are three push mechanisms 60, which are arranged equidistantly on the three vertical bases of the frame 10 in turn;

[0033] The stripping mechanism 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com