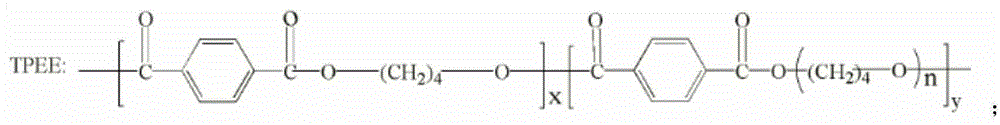

A kind of halogen-free flame-retardant thermoplastic polyester elastomer material and preparation method thereof

A thermoplastic polyester and elastomer material technology, applied in the field of polymer materials, can solve the problems of unimproved and few other properties, and achieve good thermal stability and dimensional stability, reduced smoke emission, and compatibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

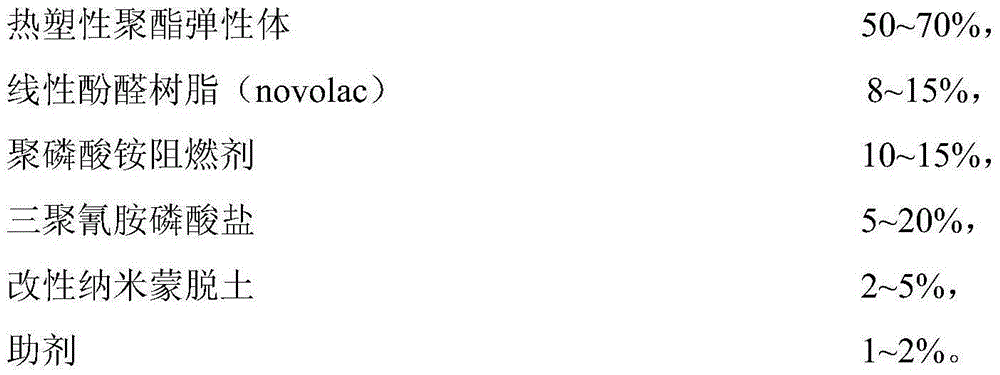

Method used

Image

Examples

Embodiment 1

[0036] Pretreatment: The raw material TPEE (H3030) was vacuum-dried at 100°C for 4 hours to obtain dry TPEE for use.

[0037] The silane coupling agent is used to treat the modified nano-montmorillonite, and the silane coupling agent KH560 is dissolved in ethanol to prepare a solution with a concentration of 0.1% (mass fraction, wt%). At the same time, a small amount of water (silane coupling agent mass 2%) under the condition of high-speed stirring, spray it into a fine mist solution, treat the modified nano-montmorillonite for 30 minutes, dry it in a vacuum oven at 80°C, and grind it before use.

[0038]Mix the dried TPEE and phenolic resin according to the mass percentage ratio, then add ammonium polyphosphate flame retardant, melamine phosphate (BASFMP), modified nano-montmorillonite and additives into the mixer and stir evenly. The ratio is, TPEE is 70%, novolac resin 8%, ammonium polyphosphate flame retardant (grade AP422) 10%, melamine phosphate (BASFMP) 9%, 2% modified...

Embodiment 2

[0042] Pretreatment: The raw material TPEE (H3303) was vacuum-dried at 100°C for 4 hours to obtain dry TPEE for use.

[0043] The silane coupling agent is used to treat the modified nano-montmorillonite, and the silane coupling agent KH560 is dissolved in ethanol to prepare a solution with a concentration of 0.1% (mass fraction, wt%). At the same time, a small amount of water (silane coupling agent mass 2%) under the condition of high-speed stirring, spray it into a fine mist solution, treat the modified nano-montmorillonite for 30 minutes, dry it in a vacuum oven at 80°C, and grind it before use.

[0044] Mix the dried TPEE and phenolic resin according to the mass percentage ratio, then add ammonium polyphosphate flame retardant, melamine phosphate (BASFMP), modified nano-montmorillonite and additives into the mixer and stir evenly. The ratio is, TPEE is 60%, 15% novolac resin, 13% ammonium polyphosphate flame retardant (brand AP420), 5% melamine phosphate (BASFMP), 5% modifi...

Embodiment 3

[0048] Pretreatment: The raw material TPEE (H3303) was vacuum-dried at 100°C for 4 hours to obtain dry TPEE for use.

[0049] The silane coupling agent is used to treat the modified nano-montmorillonite, and the silane coupling agent KH560 is dissolved in ethanol to prepare a solution with a concentration of 0.1% (mass fraction, wt%). At the same time, a small amount of water (silane coupling agent mass 2%) under the condition of high-speed stirring, spray it into a fine mist solution, treat the modified nano-montmorillonite for 30 minutes, dry it in a vacuum oven at 80°C, and grind it before use.

[0050] Mix the dried TPEE and phenolic resin according to the mass percentage ratio, then add ammonium polyphosphate flame retardant, melamine phosphate (BASFMP), modified nano-montmorillonite and additives into the mixer and stir evenly. The ratio is, TPEE is 50%, novolac resin 15%, ammonium polyphosphate flame retardant (grade AP420) 13%, melamine phosphate (BASFMP) 15%, 5% modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com