A kind of super low temperature resistant fully synthetic diesel engine oil and its preparation method

A fully synthetic, diesel engine technology, used in the petroleum industry, lubricating compositions, base materials, etc., to achieve excellent ultra-low temperature unbounded startability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of ultra-low temperature resistant fully synthetic diesel engine oil, comprising the following steps:

[0033] 1) Under the catalytic polymerization of toluene, alkylbenzene and polymer binary ethylene propylene hydrocarbon are stirred and reacted at 80-110°C for 2-4 hours to obtain base oil;

[0034] 2) Stir molybdenum anti-wear energy-saving agent and dispersant at 40-60°C for 1-2 hours, then add boronized ashless dispersant, anti-oxidant and anti-corrosion agent and detergent and stir at 40-60°C for 1-2 hours 2 hours, get compound additive;

[0035] 3) Stir the base oil obtained in step 1 and the composite additive obtained in step 2 at 30-50°C for 1-2 hours, and perform coarse and fine filtration to obtain super low-temperature resistant fully synthetic diesel engine oil.

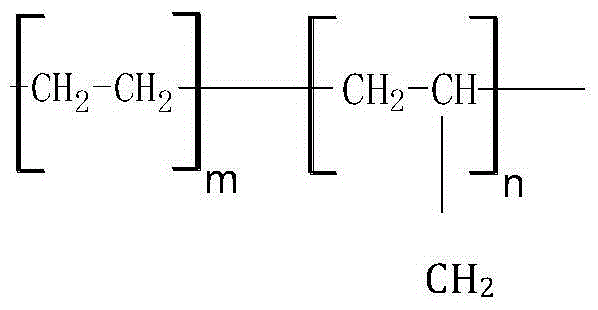

[0036] Among them, the polymer binary ethylene propylene hydrocarbon is a binary ethylene propylene rubber obtained by copolymerization o...

Embodiment 1

[0039] The invention provides a super low temperature resistant fully synthetic diesel engine oil, which consists of the following components in parts by weight:

[0040] 80 parts of alkylbenzene, 2 parts of polymer binary ethylene propylene hydrocarbon, 2 parts of toluene, 3 parts of high alkali value synthetic calcium sulfonate, 2.5 parts of monoalkenyl succinimide, 1.5 parts of thiadiazole derivatives, boron 3.5 parts of chemical ashless dispersant, 1.8 parts of molybdenum dialkyldithiophosphate.

[0041] Diesel engine oil preparation method:

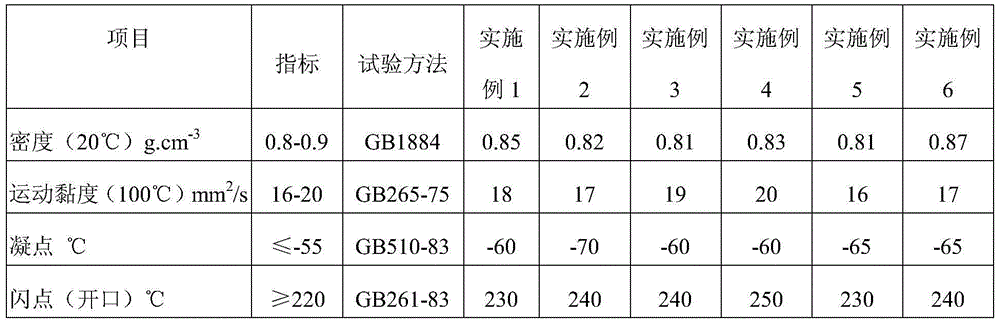

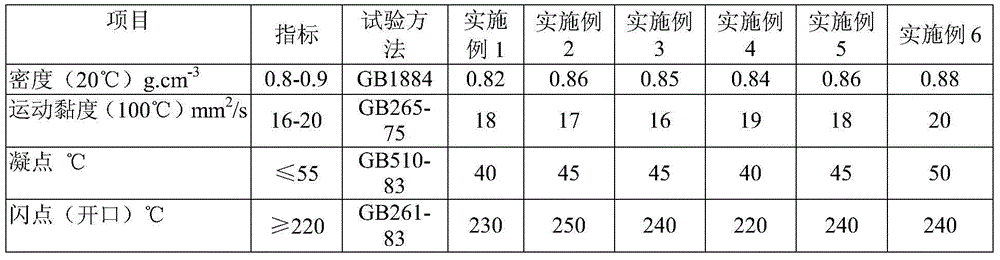

[0042] 1) Mix the high-molecular binary ethylene propylene hydrocarbon with alkylbenzene in an enamel reaction kettle, drop toluene into it with a dropper, and react under toluene catalytic polymerization at 95°C for 3 hours, then vacuum extract the toluene to obtain the base oil; the index detection results of base oil are as shown in table 1;

[0043] 2) Stir dialkylmolybdenum dithiophosphate and monoalkenyl succinimide at 50°C f...

Embodiment 2

[0050] The invention provides a super low temperature resistant fully synthetic diesel engine oil, which consists of the following components in parts by weight:

[0051] 75 parts of alkylbenzene, 1 part of polymer binary ethylene propylene hydrocarbon, 1 part of xylene, 2 parts of calcium alkyl salicylate, 2 parts of polyisobutylene bis-succinimide, 1 part of zinc salt of sulfur phosphorus secondary alcohol , 3 parts of boride ashless dispersant, 0.5 parts of sulfur phosphorus nitrogen molybdenum complex.

[0052] Diesel engine oil preparation method:

[0053] 1) Mix the high-molecular binary ethylene propylene hydrocarbon with alkylbenzene in an enamel reaction kettle, drop xylene into it with a dropper, under the catalytic polymerization of toluene, stir and react at 110°C for 2 hours, and then vacuum extract the toluene to obtain Base oil; each index detection result of base oil is as shown in table 1;

[0054] 2) Stir the sulfur phosphorus nitrogen molybdenum complex wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com