Anti-dropping transmission shaft assembly for positive displacement motor

A technology of screw drilling tools and drive shafts, which is used in the drilling driving device, drilling equipment, earth-moving drilling and other directions in the wellbore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

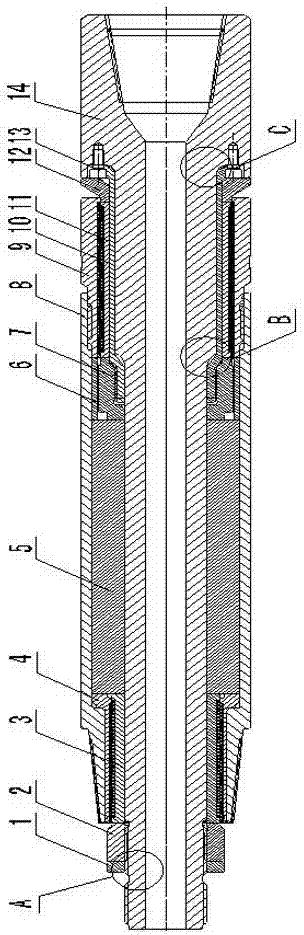

[0011] As shown in the figure, an anti-dropping drive shaft assembly for screw drilling tools is mainly composed of upper radial bearing inner sleeve 3, upper radial bearing outer sleeve 4, thrust bearing 5, upper bearing shell 8, lower bearing shell 9, and The radial bearing inner sleeve 11 and the transmission shaft 14 are composed. The upper radial bearing inner sleeve 3 and the upper radial bearing outer sleeve 4 are arranged at the front end of the transmission shaft 14, the thrust bearing 5 is arranged in the middle of the transmission shaft 14, and the upper bearing shell 8 is arranged in the thrust On the surface of the bearing 5, the lower radial bearing inner sleeve 11 is arranged at the rear of the transmission shaft 14, the lower bearing shell 9 is located outside the lower radial bearing inner sleeve 11 and connected to the upper bearing shell 8, between the thrust bearing 5 and the lower bearing shell 9 Set the thrust ring 6, set an upper anti-drop nut 2 in front o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com