Mine cooling system

A mine, temperate zone technology, applied in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc., can solve the problems of low efficiency, huge waste of cooling capacity, complex system, etc., to reduce heat exchange links and reduce inlet air temperature. , the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

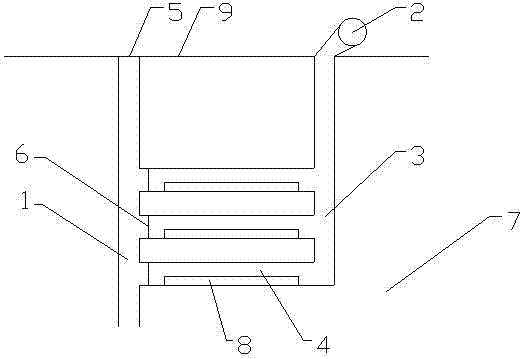

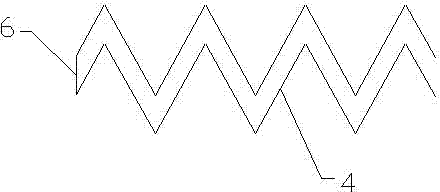

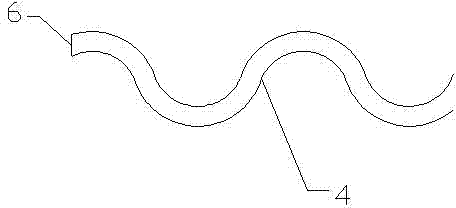

[0028] Accompanying drawing is the specific embodiment of the present invention. Such as figure 1 As shown, this kind of mine cooling system includes an air intake shaft 1 below the ground 9, a cooling air intake shaft 3 is excavated next to the air intake shaft 1, and several cooling air intake shafts are dug horizontally after the cooling air intake shaft 3 is connected to the stratum constant temperature zone 7. Lane 4 communicates with air inlet shaft 1, in order to enhance the cooling effect, a container for adorning ice or spray water pipe 8 can also be added in cooling lane 4; figure 2 and image 3 As shown, the cooling lane 4 can be designed in a wavy or sawtooth shape, so that the hot air can absorb more cold air in the cooling lane 4, and the cooling effect is better; an opening and closing door is installed at the point where the cooling lane 4 communicates with the air inlet shaft 1 6. A fan 2 is provided at the entrance of the cooling air intake shaft 3, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com