Marine center type multi-layer hard seal butterfly valve

A hard seal, marine technology, applied in the direction of shaft seal, lift valve, valve details, etc., can solve the problems of short service life, easy leakage, poor sealing performance of sealing ring, etc., and achieve long service life, small wear and good sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

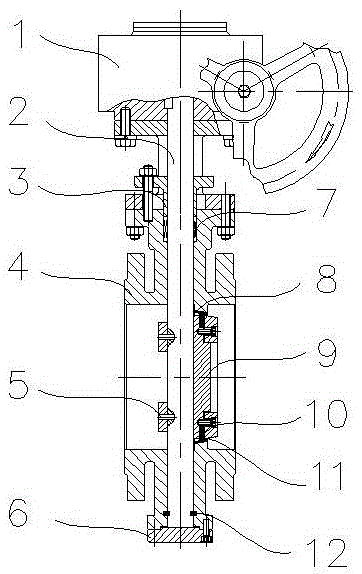

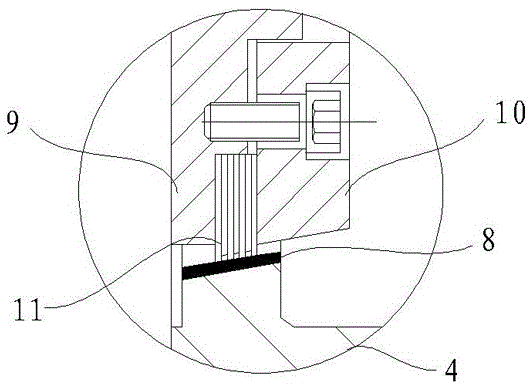

[0015] Embodiment one, such as Figure 1 to Figure 2 As shown, a marine center type multi-layer hard-sealed butterfly valve is used for marine and ocean-going ships, including a driving part 1, a valve body 4, a valve stem 2 and a disc plate 9. The driving part can be worm gear transmission, electric, pneumatic, etc. Mechanism, the valve stem passes through the valve body, the outer end of the valve stem is connected with the driving part, the disc plate is located in the valve body, one side of the disc plate is fixed on the valve stem with cylindrical pin 5, and the other side of the disc plate is fixedly connected with a sealing Ring 11, the sealing ring is pressed by the pressure plate 10 and fixed on the disc plate by screws. The inner wall of the valve is a conical inclined surface, the large end of the conical inclined surface faces the valve stem, and a layer of wear-resistant metal layer 8 with uniform thickness is welded on the inner wall of the valve. The circumfer...

Embodiment 2

[0016] Embodiment 2, the thickness of the metal sheet forming a sealing pair with the inner wall of the valve gradually increases from the side close to the valve stem to the side away from the valve stem. All the other structures and methods of use are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com