Anti-collision valve for fore peak

A forepeak tank and anti-collision technology, applied in the direction of valve lift, valve details, valve device, etc., can solve problems such as time-consuming, inconvenient use, troublesome opening or closing, etc., to improve safety, improve work efficiency, and avoid waste The effect of the itinerary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

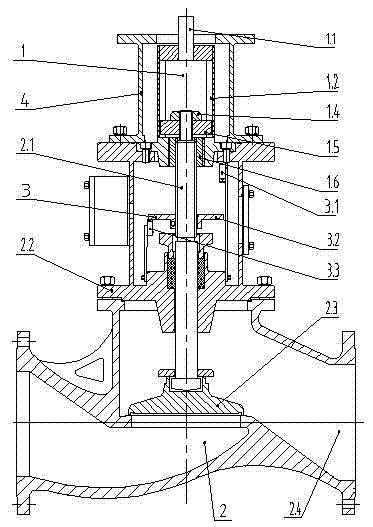

[0018] The fore peak tank anti-collision valve shown in the accompanying drawings includes a screw-type stop valve 2, an executive drive structure 1, and a stroke control mechanism 3; the screw-type stop valve 2 includes a valve stem 2.1, a valve cover 2.2, a valve disc 2.3, a bushing 1.6 and The valve body 2.4; the bonnet 2.2 is a sleeve-type hollow structure with upper and lower end flanges; the valve stem 2.1 runs through the bonnet 2.2 upwards, and the bushing 1.6 is fixedly connected to the middle part of the upper flange of the bonnet 2.2, and the valve stem 2.1 and the bushing The sleeve 1.6 is threaded; the actuator drive structure 1 is set on the valve cover 2.2, including the spline 1.1, the drive sleeve 1.2, the slider 1.5, and the tightening nut 1.4; the spline 1.1 is fixedly connected to the middle of the upper end of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com