Natural cooler for steam exhaust system of continuous casting machine

A natural cooling and steam exhaust technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as ineffective use of heat energy, waste of water resources, hidden safety hazards, etc., to achieve strong versatility and energy saving The effect of water volume and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

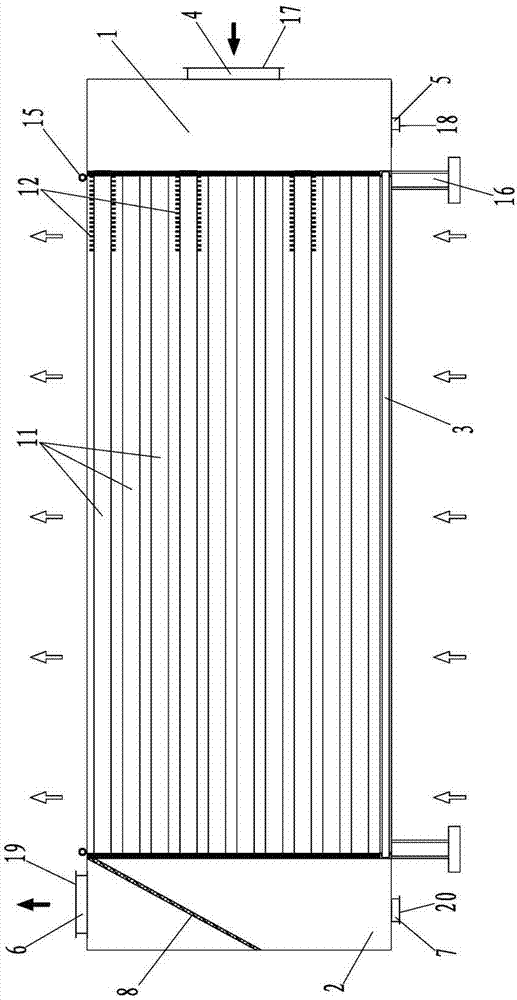

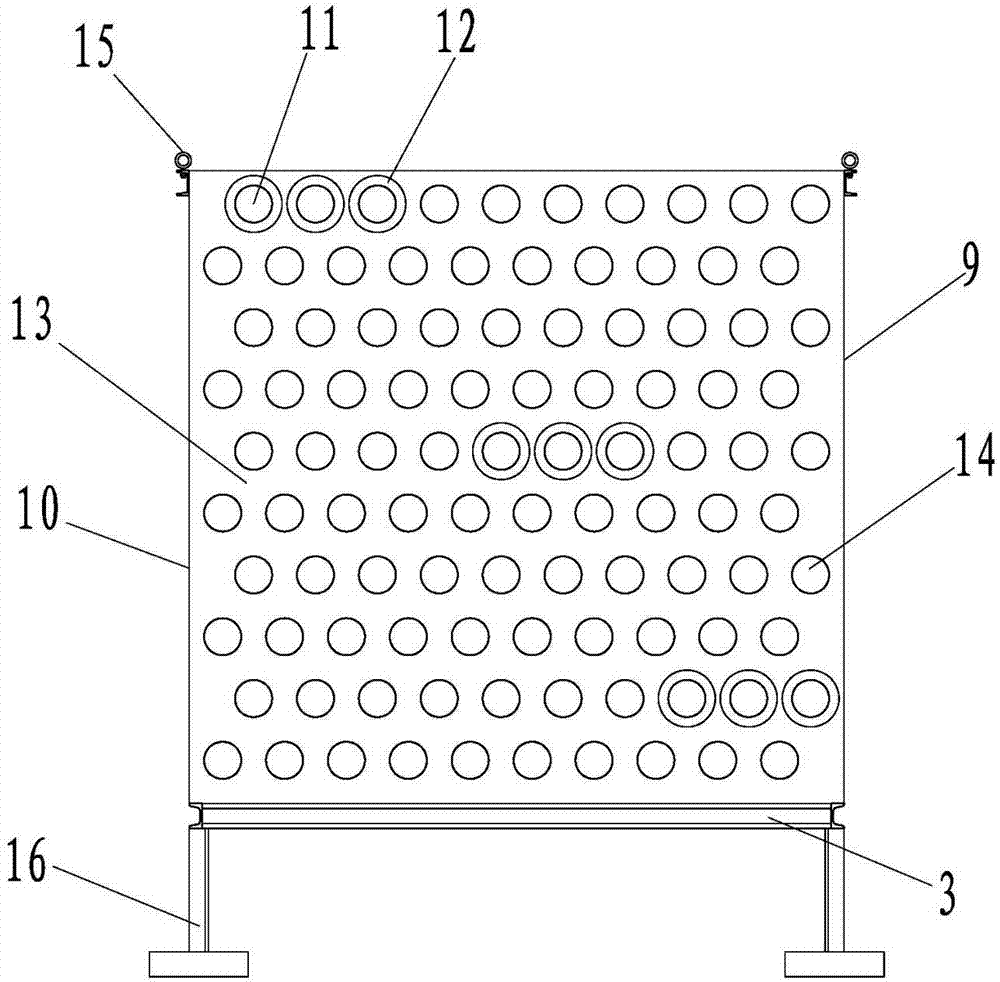

[0018] Such as figure 1 and figure 2 As shown, the natural cooler for the steam exhaust system of the continuous casting machine of the present invention includes right and left air intake boxes 1, exhaust boxes 2 and a hollow rectangular frame welded between the bottoms of the air intake boxes 1 and exhaust boxes 2 3. The right side plate of air intake box 1 is provided with air inlet 4, is provided with the first flange 17 on the air inlet 4, is provided with the first water outlet 5 on its lower plate, is provided with the first water outlet 5 A connection flange 18 . The upper plate of the exhaust box 2 is provided with an exhaust port 6, the exhaust port 6 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com