Novel twistable flapping wing structure and flapping wing twisting method

A wing structure and a new type of technology, applied in the field of bionic aircraft, can solve the problems of increased consumption, increased wing complexity and burden, poor control efficiency, etc., and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

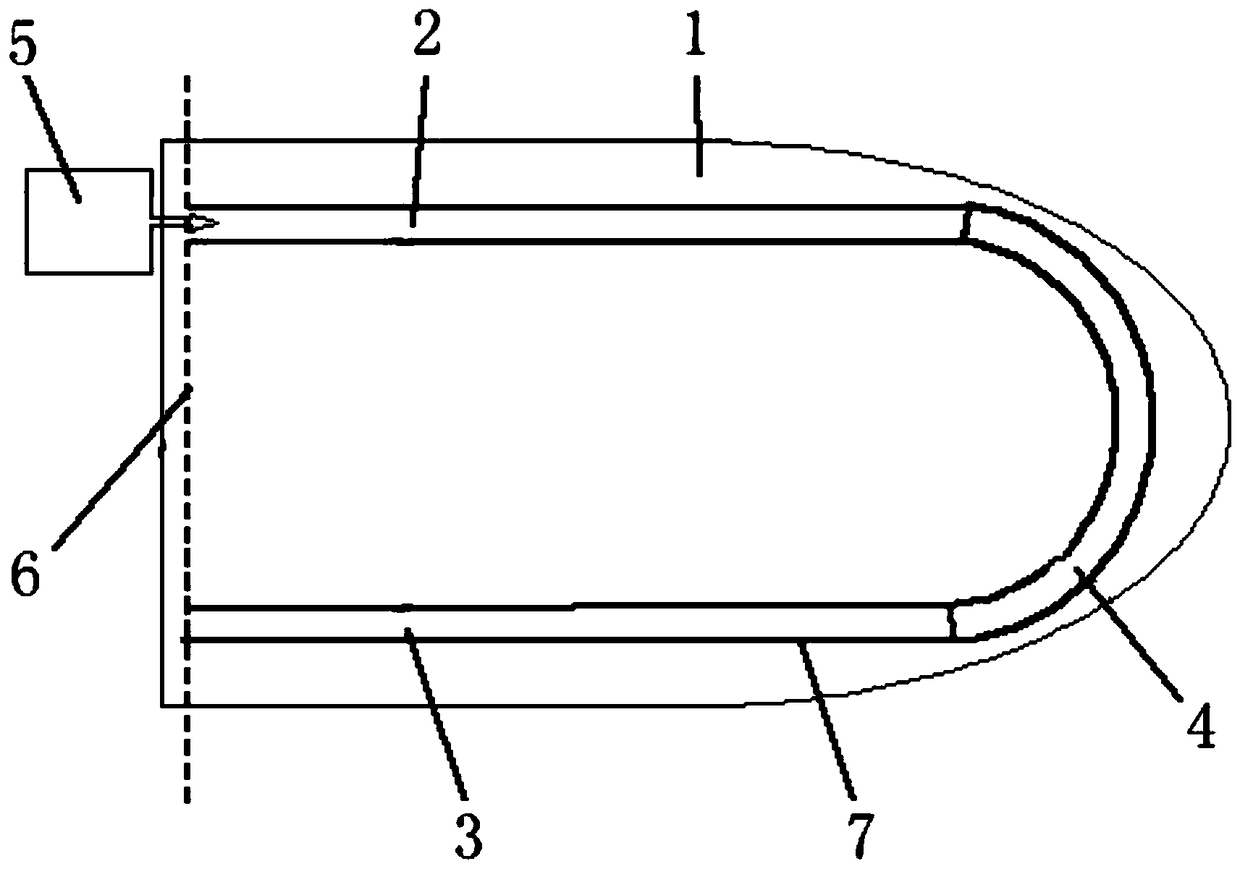

[0075] A new type of twistable flapping wing structure, including wings, pipes, and pumps. The root of the wing is a flapping shaft, and the wings perform flapping vibration around the flapping shaft. The pipeline is located inside the wing, and the pipe Including an inflow section, a connection section and an outflow section, the pump communicates with the pipeline, and the pump circulates the fluid in the pipeline.

[0076] The ducts are arranged spanwise inside the wing.

[0077] The inflow section is located at the leading edge of the wing.

[0078] The outflow section is located at the trailing edge of the wing.

Embodiment 2

[0080] A flapping wing twisting method adopts a twistable flapping wing structure, the twistable flapping wing structure includes wings, pipes, and pumps, the root of the wing is a flapping wing shaft, and the wings perform flapping vibration around the flapping wing shaft , the pipeline is located inside the wing, the pipeline includes an inflow section, a connection section and an outflow section, the pump communicates with the pipeline, and the pump circulates the fluid in the pipeline.

[0081] The ducts are arranged spanwise inside the wing.

[0082] The inflow section is located at the leading edge of the wing.

[0083] The outflow section is located at the trailing edge of the wing. The torsion frequency is automatically matched with the flapping frequency.

[0084] Turn on the pump to circulate the fluid in the pipeline, so that the twist can be generated during the flapping process.

[0085] Evaluation Test One

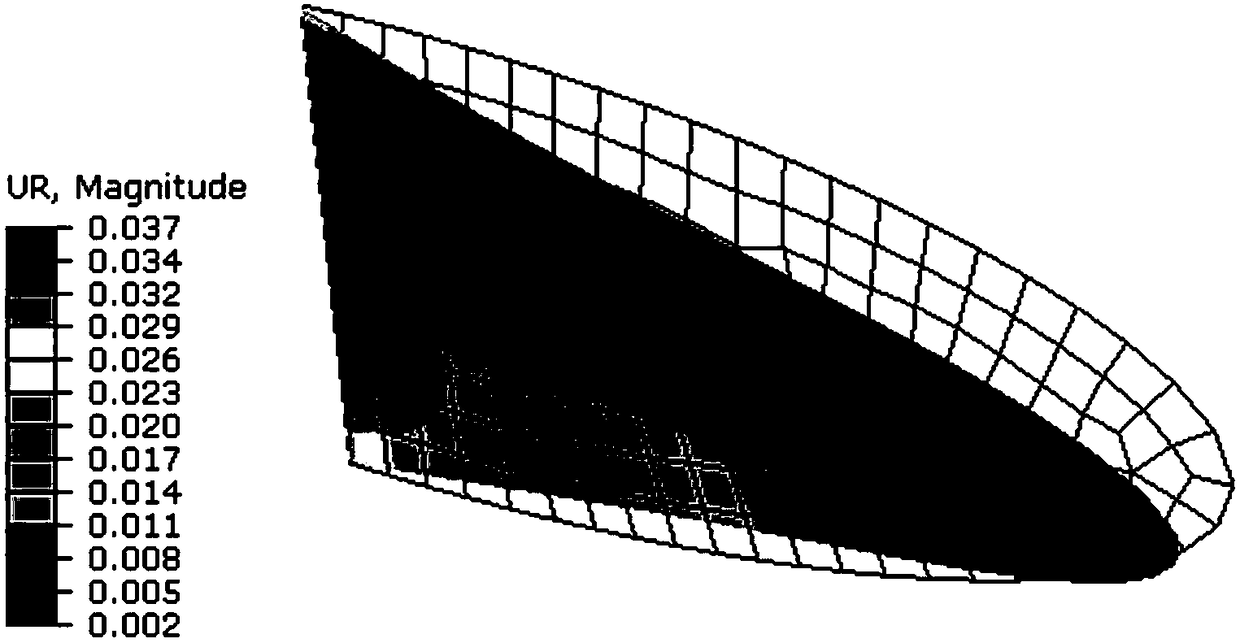

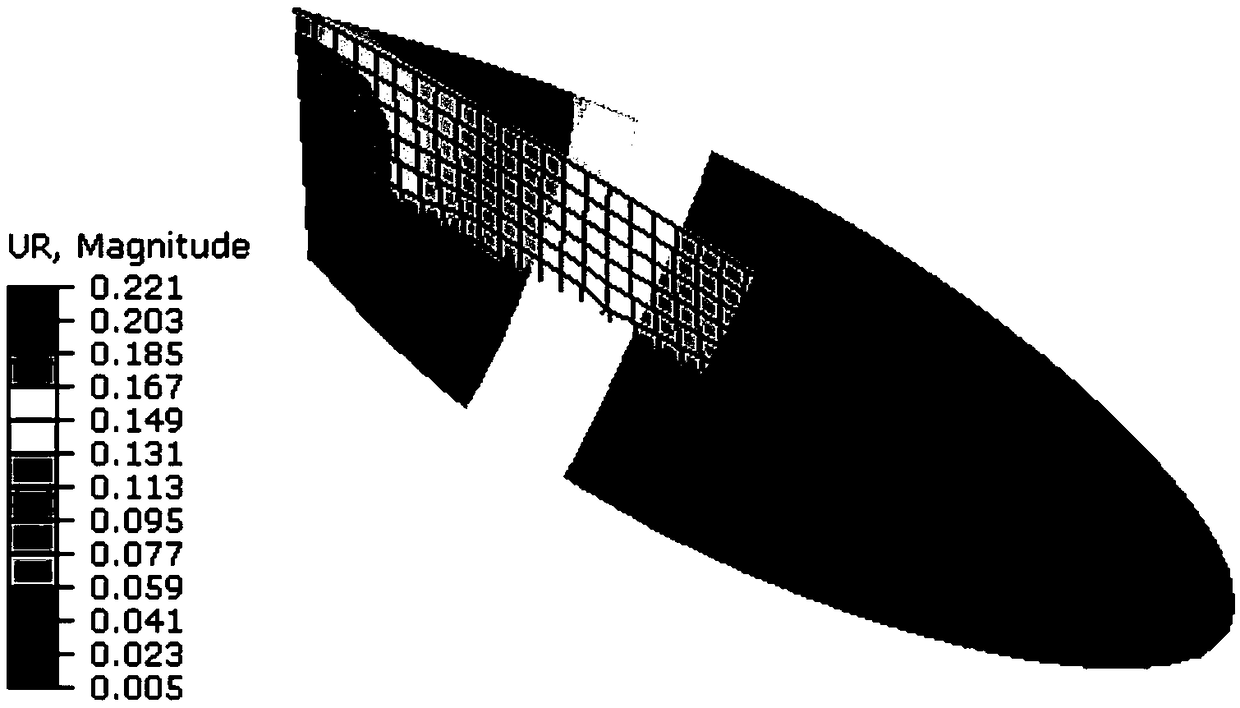

[0086] The finite element software Abaqus is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com