A rear automobile lamp detecting clamp of an automobile lamp air tightness detecting machine

A technology for detecting fixtures and rear lights, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem that it is impossible to detect all unqualified products, and there is no such airtightness Problems such as airtightness detection and waste of labor costs, etc., to achieve effective and rapid airtightness detection, reduce labor costs, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

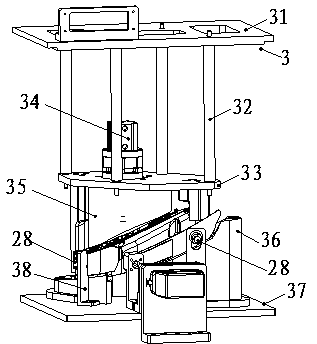

[0008] See figure 1 , The embodiment of the present invention includes:

[0009] A rear lamp detection fixture for a vehicle light airtight tester. The rear lamp test fixture 3 of the vehicle light airtight tester includes four small uprights 32 on the lower surface of the top plate 31 of the rear lamp fixture. The lower end of the small column 32 is connected to the middle template 33, the upper plane of the middle template 33 is equipped with a pressurizing cylinder 34, the lower plane of the middle template 33 is installed with a semi-closed top mold 35, and the lower part of the semi-closed top mold 35 is the left bottom right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com