Air tightness test system for top shutter cylinder

An air-tightness testing and shutter technology is applied in the field of air-tightness testing systems for cylinders of roof shutters, which can solve the problems of low efficiency and cumbersome detection process of cylinders of roof shutters, and achieve the effects of improving detection efficiency and simple detection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

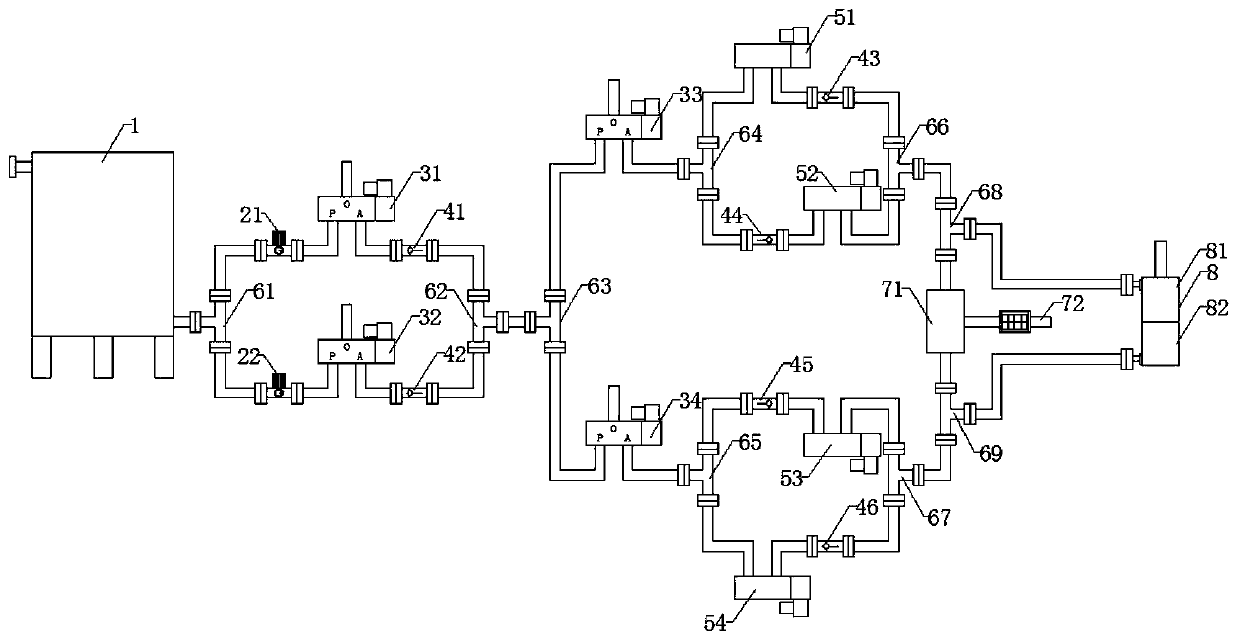

[0014] Such as figure 1 and 2 As shown, a top louver cylinder air tightness testing system includes a high-pressure air source 1, the outlet end of the high-pressure air source 1 is connected to the first pressure regulating valve 21 and the second pressure regulating valve 22 through the first three-way joint 61. The gas end is connected, the gas outlets of the first pressure regulating valve 21 and the second pressure regulating valve 22 are respectively connected with the intake ports of the first two-position three-way solenoid valve 31 and the second two-position three-way solenoid valve 32, the first two The working ends of the position three-way solenoid valve 31 and the second two-position three-way solenoid valve 32 are connected with the intake ports of the first check valve 41 and the second check valve 42 respectively, and the first check valve 41 and the second check valve The outlet end of the valve 42 is connected to the third three-way joint 63 through the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com