Natural gas pipeline quality detection device

A technology for natural gas pipelines and detection devices, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of complex operation, low work efficiency, inconvenient use, etc. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

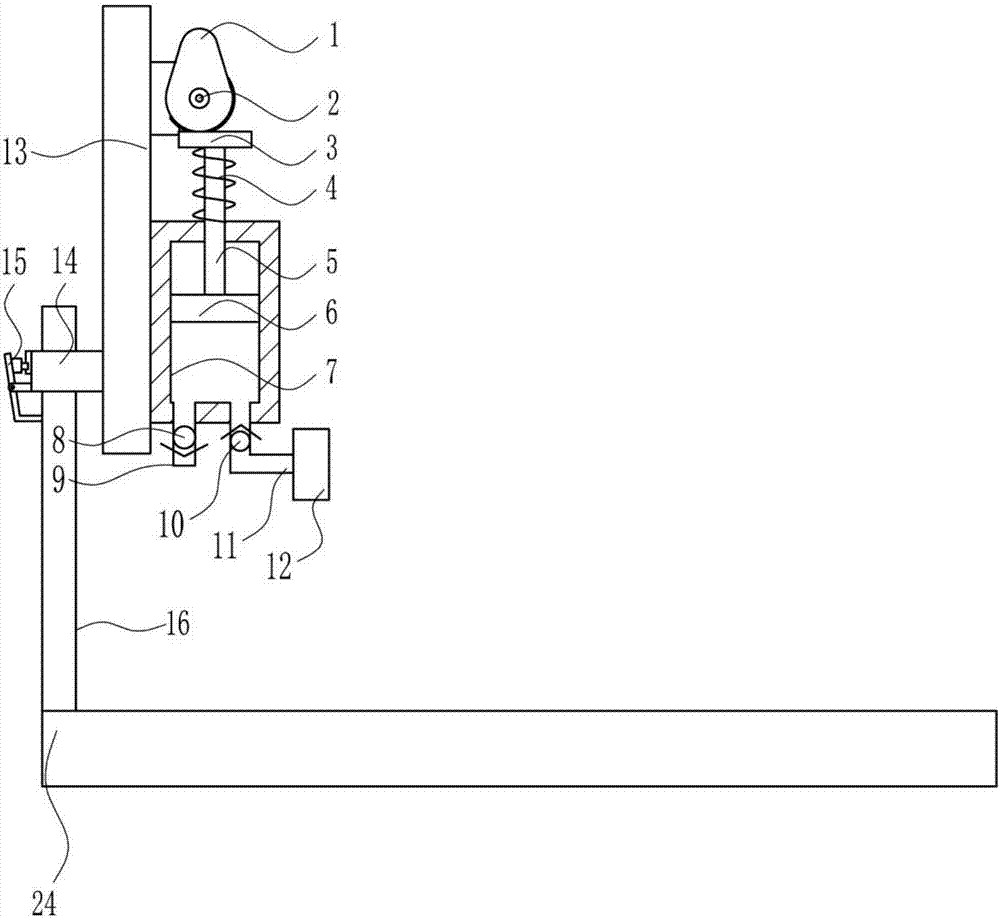

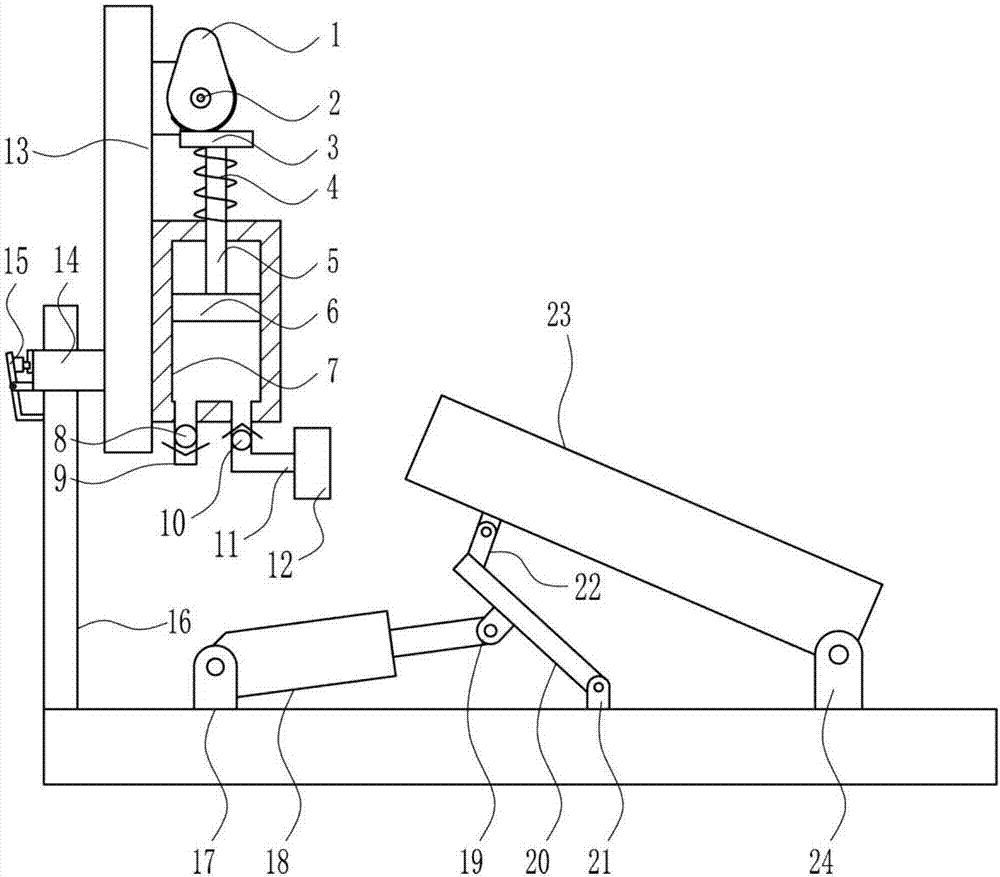

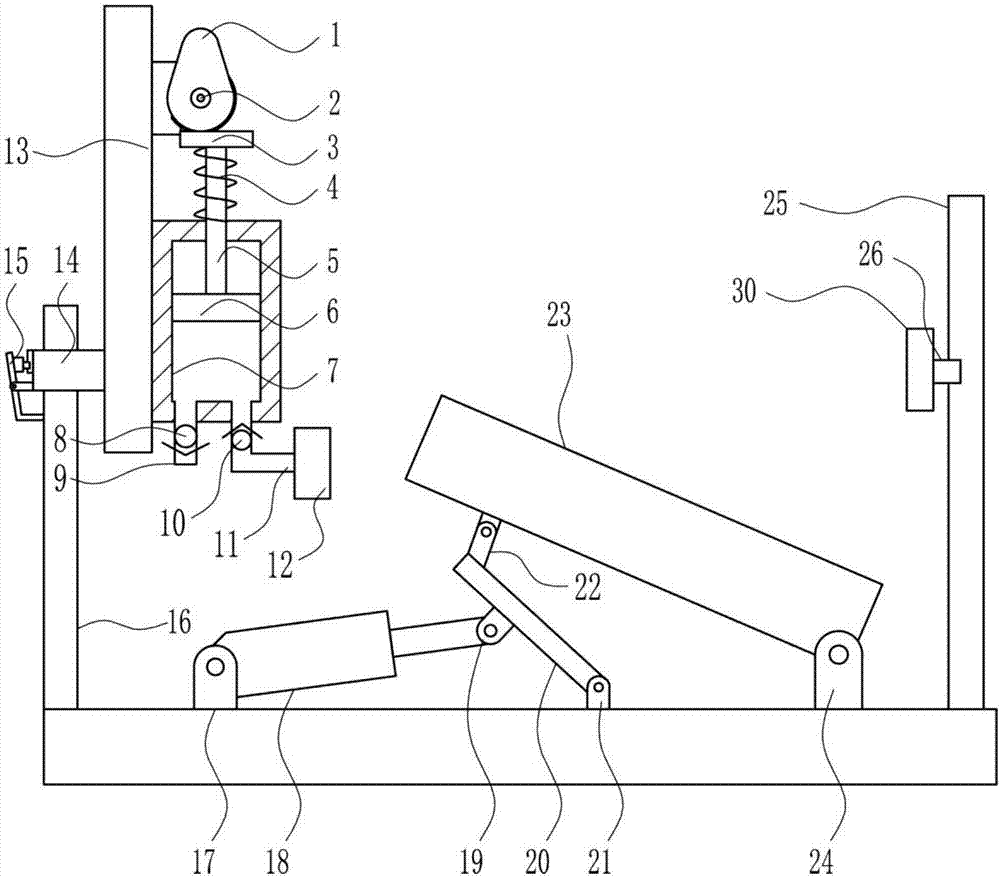

[0026] A natural gas pipeline quality detection device, such as Figure 1-5 As shown, it includes a cam 1, a motor 2, a connecting plate 3, a first spring 4, a lifting rod 5, a piston 6, a cylinder 7, a first one-way valve 8, an intake pipe 9, a second one-way valve 10, an outlet Trachea 11, airtight plug 12, support rod 13, sliding sleeve 14, base plate, locking device 15 and slide bar 16, base plate left upper part is equipped with slide bar 16, slide bar 16 is provided with sliding sleeve 14, and sliding sleeve 14 Locking device 15 is installed on the left side, and support rod 13 is installed on the right part of sliding sleeve 14, and motor 2 is installed on the upper right part of support rod 13, and cam 1 is provided on motor 2, and cylinder body 7 is installed on the lower right part of support rod 13, and cylinder The piston 6 is slidingly arranged in the body 7, the lifting rod 5 is installed on the top of the piston 6, the connecting plate 3 is installed on the top ...

Embodiment 2

[0028] A natural gas pipeline quality detection device, such as Figure 1-5 As shown, it includes a cam 1, a motor 2, a connecting plate 3, a first spring 4, a lifting rod 5, a piston 6, a cylinder 7, a first one-way valve 8, an intake pipe 9, a second one-way valve 10, an outlet Trachea 11, airtight plug 12, support rod 13, sliding sleeve 14, base plate, locking device 15 and slide bar 16, base plate left upper part is equipped with slide bar 16, slide bar 16 is provided with sliding sleeve 14, and sliding sleeve 14 Locking device 15 is installed on the left side, and support rod 13 is installed on the right part of sliding sleeve 14, and motor 2 is installed on the upper right part of support rod 13, and cam 1 is provided on motor 2, and cylinder body 7 is installed on the lower right part of support rod 13, and cylinder The piston 6 is slidingly arranged in the body 7, the lifting rod 5 is installed on the top of the piston 6, the connecting plate 3 is installed on the top ...

Embodiment 3

[0031] A natural gas pipeline quality detection device, such as Figure 1-5As shown, it includes a cam 1, a motor 2, a connecting plate 3, a first spring 4, a lifting rod 5, a piston 6, a cylinder 7, a first one-way valve 8, an intake pipe 9, a second one-way valve 10, an outlet Trachea 11, airtight plug 12, support rod 13, sliding sleeve 14, base plate, locking device 15 and slide bar 16, base plate left upper part is equipped with slide bar 16, slide bar 16 is provided with sliding sleeve 14, and sliding sleeve 14 Locking device 15 is installed on the left side, and support rod 13 is installed on the right part of sliding sleeve 14, and motor 2 is installed on the upper right part of support rod 13, and cam 1 is provided on motor 2, and cylinder body 7 is installed on the lower right part of support rod 13, and cylinder The piston 6 is slidingly arranged in the body 7, the lifting rod 5 is installed on the top of the piston 6, the connecting plate 3 is installed on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com