Single-core optical cable for indoor and outdoor jumper wires and preparing method thereof

A single-core optical cable and jumper technology, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of high cost, unsatisfactory waterproof performance, flame retardancy performance, and unsatisfactory bending and tensile strength, so as to prevent damage and achieve good performance. The effect of bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

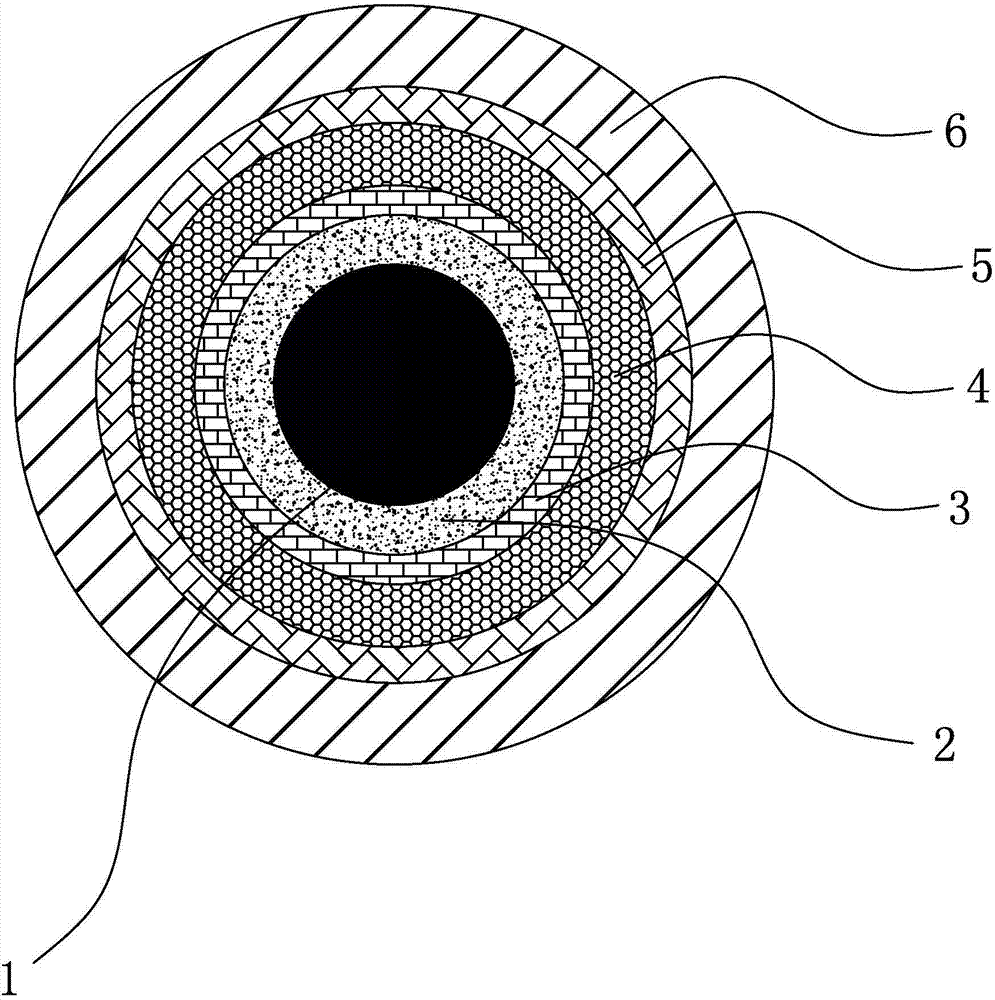

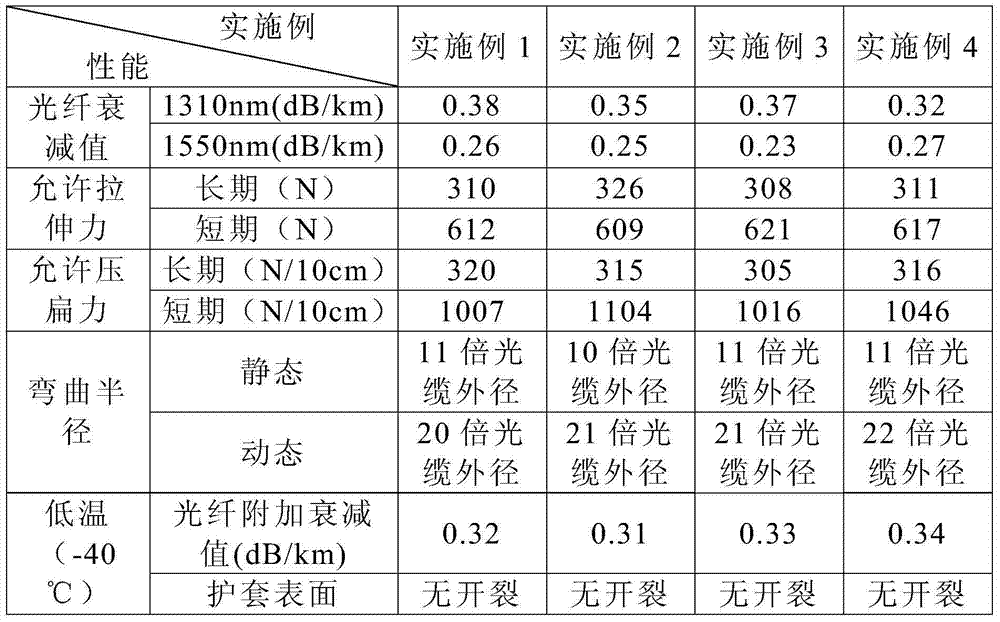

[0027] First, select the G.657 bend-insensitive optical fiber, and then use an extruder to coat the outer surface of the optical fiber with LSZH material with a pH weight of 4.8, a conductivity weight of 9.2 μs / mm, and a minimum light transmittance of 75%. The tight cladding layer with a thickness of 0.3mm is wrapped around the outer surface of the tight cladding layer with a second water-blocking reinforcement layer with a thickness of 0.1mm made of water-blocking aramid yarn. Surface coating PH weighted value is 4.8, conductivity weighted value is 9.2μs / mm, the minimum light transmittance is 75% LSZH material made of 0.45mm thick inner sheath, the outer surface of the inner sheath is wrapped around The first water-blocking reinforcing layer with a thickness of 0.15mm is made of water glass yarn, and finally, the outer surface of the first water-blocking reinforcing layer is coated with a PE material with an oxygen index of 33 through an extruder and an outer layer with a thic...

Embodiment 2

[0029] First, select the G.657 bend-insensitive optical fiber, and then use an extruder to coat the outer surface of the optical fiber with a PVC material with a pH weighted value of 5.0, a conductivity weighted value of 8.5 μs / mm, and a minimum light transmittance of 78%. The tight cladding layer with a thickness of 0.25 mm is wrapped around the outer surface of the tight cladding layer to form a second water-blocking reinforcement layer with a thickness of 0.15 mm, and the outer surface of the second water-blocking reinforcement layer is formed by an extruder. Coating PH weighted value is 5.2, conductivity weighted value is 8.8μs / mm, and the inner sheath is made of TPU material with a minimum light transmittance of 80% and a thickness of 0.35mm. The outer surface of the inner sheath is wrapped to block water The first water-blocking reinforcing layer with a thickness of 0.2mm is made of glass yarn, and finally the outer surface of the first water-blocking reinforcing layer is...

Embodiment 3

[0031]First, select the G.657 bend-insensitive optical fiber, and then use an extruder to coat the outer surface of the optical fiber with Nylon material with a pH weighted value of 5.0, a conductivity weighted value of 9.0 μs / mm, and a minimum light transmittance of 79%. A tight cladding layer with a thickness of 0.35mm is wrapped around the outer surface of the tight cladding layer to make a second water-blocking reinforcing layer with a thickness of 0.2mm, and the second water-blocking reinforcing layer is formed by an extruder. The surface coating has a PH weighted value of 5.3, an electrical conductivity weighted value of 8.5μs / mm, and a minimum light transmittance of 82%. The inner sheath is made of PPO material with a thickness of 0.55mm, and the outer surface of the inner sheath is wrapped to block water. The first water-blocking reinforced layer with a thickness of 0.2mm is made of glass yarn, and finally the outer surface of the first water-blocked reinforced layer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com