Knee joint plateau steel plate

A knee joint and steel plate technology, applied in the field of knee joint platform plate, can solve the problems of general support strength, large surgical trauma, limited longitudinal support force, etc., to reduce traumatic arthritis, reduce operation time, and restore flexion and extension function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

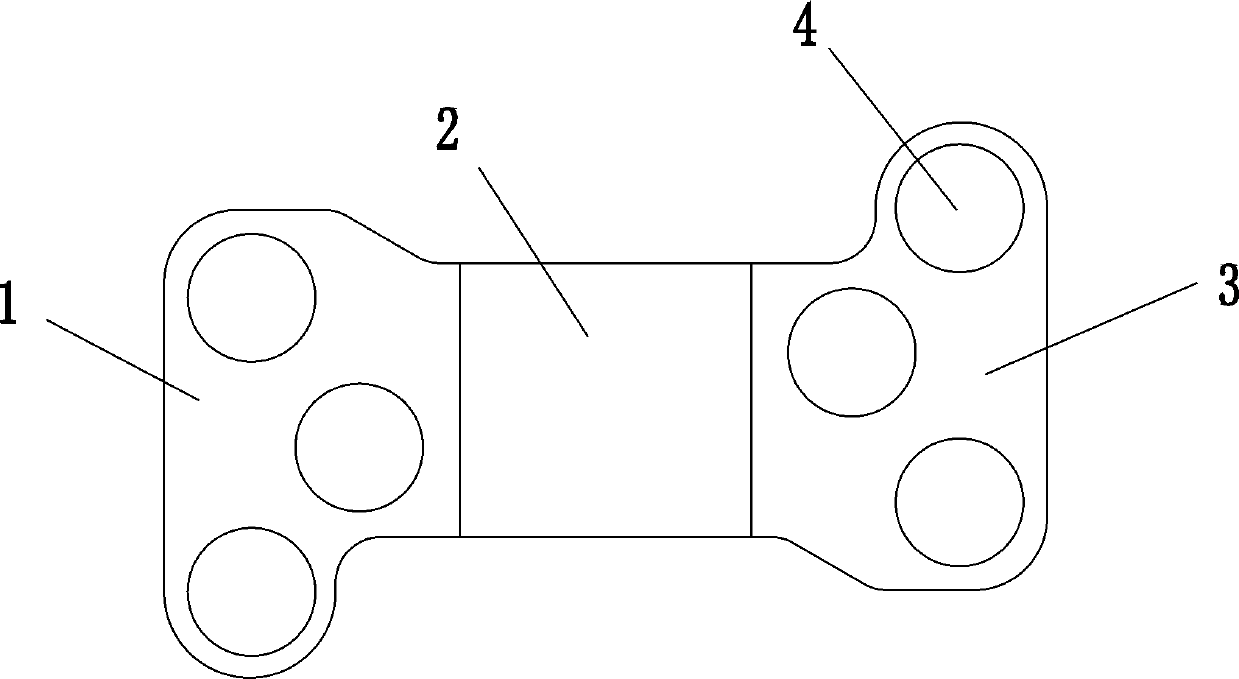

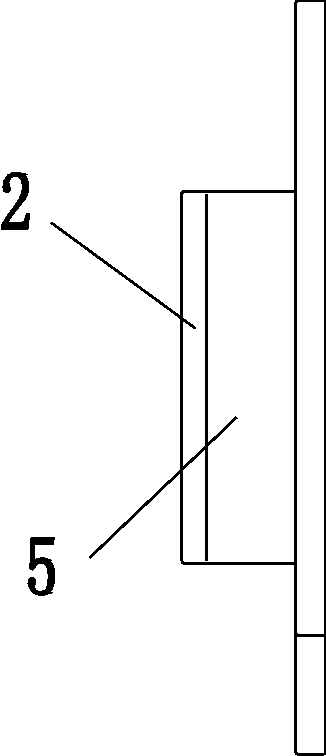

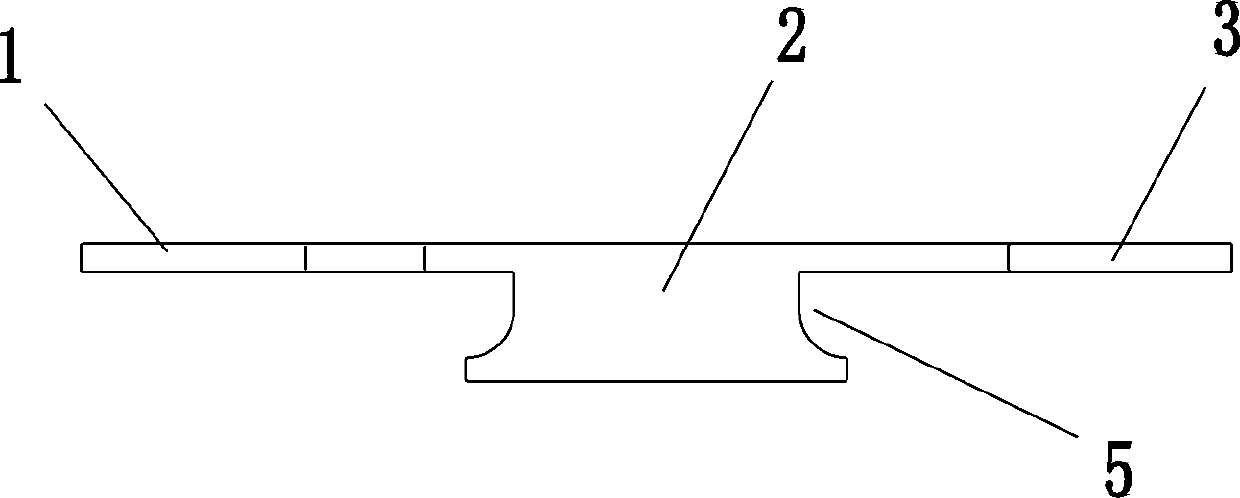

[0016] see figure 1 — Figure 4 , the present embodiment is Z-shaped as a whole, and is composed of a steel plate head 1, a plate body 2 and a steel plate tail 3, and the steel plate head 1 and the steel plate tail 3 are rotationally symmetrical with a rotation angle of 180 degrees, that is, the steel plate head 1 revolves around the central point Rotate 180 degrees to coincide with the tail part 3 of the steel plate. Three through holes 4 are respectively provided on the steel plate head 1 and the steel plate tail 3 . The thickness of the plate body 2 is greater than the thickness of the steel plate head 1 and the steel plate tail 3, the thickness of the steel plate head 1 and the steel plate tail 3 is 1.2 mm, and the thickness of the plate body 2 is 6.0 mm. Both sides of the board body 2 are provided with grooves 5 . Edges of the steel plate head 1 and the steel plate tail 3 are arc-shaped.

[0017] The steel plate head 1, the plate body 2 and the steel plate tail 3 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com