Plane two-freedom-degree nine-rod closed-chain type reach stacker

A degree of freedom, closed-chain technology, applied in the direction of lifting devices, etc., can solve the problems of high maintenance costs, high processing and assembly requirements, and short life, and achieve the effects of reduced weight, small motion inertia, and good stiffness characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

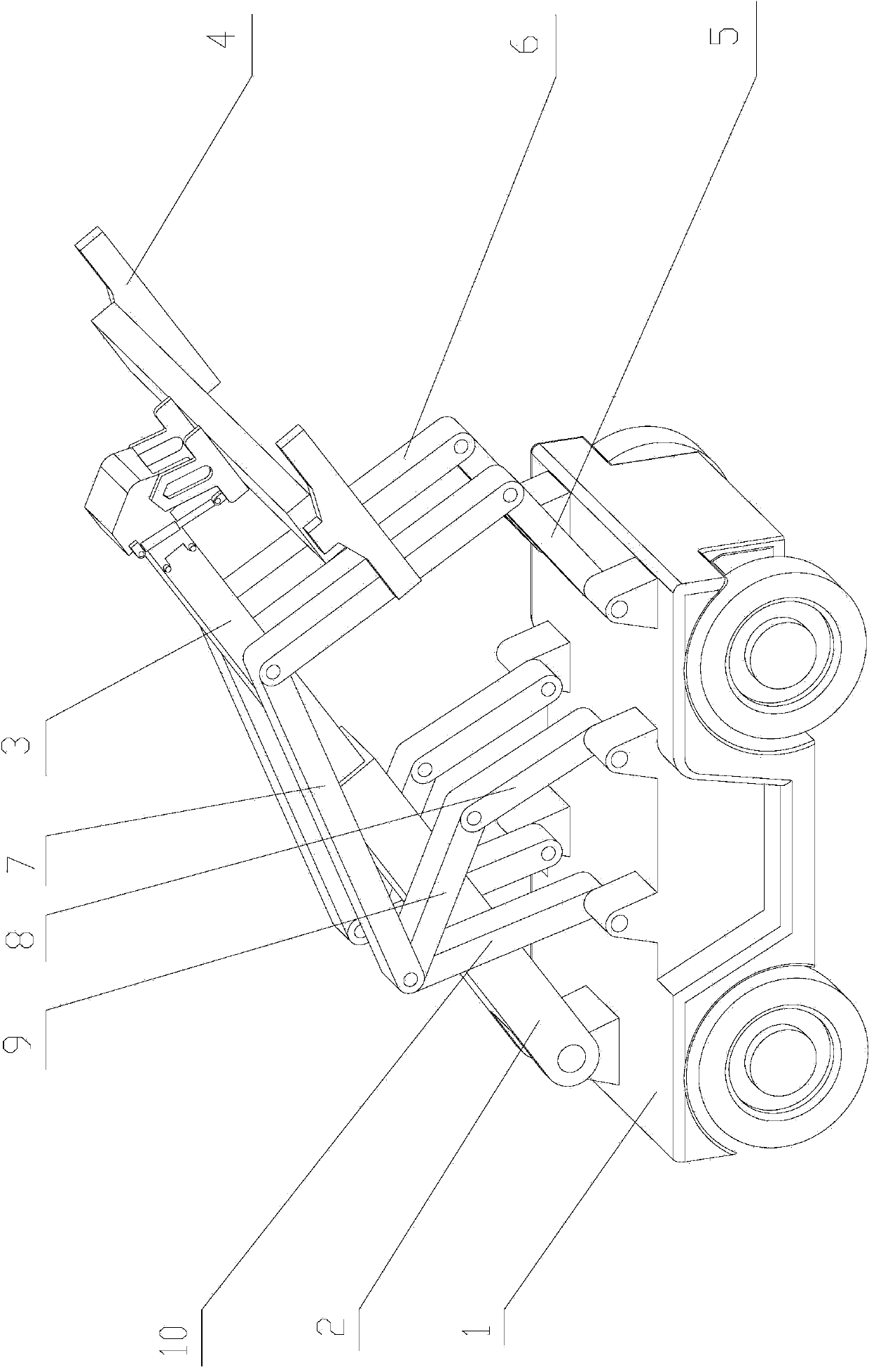

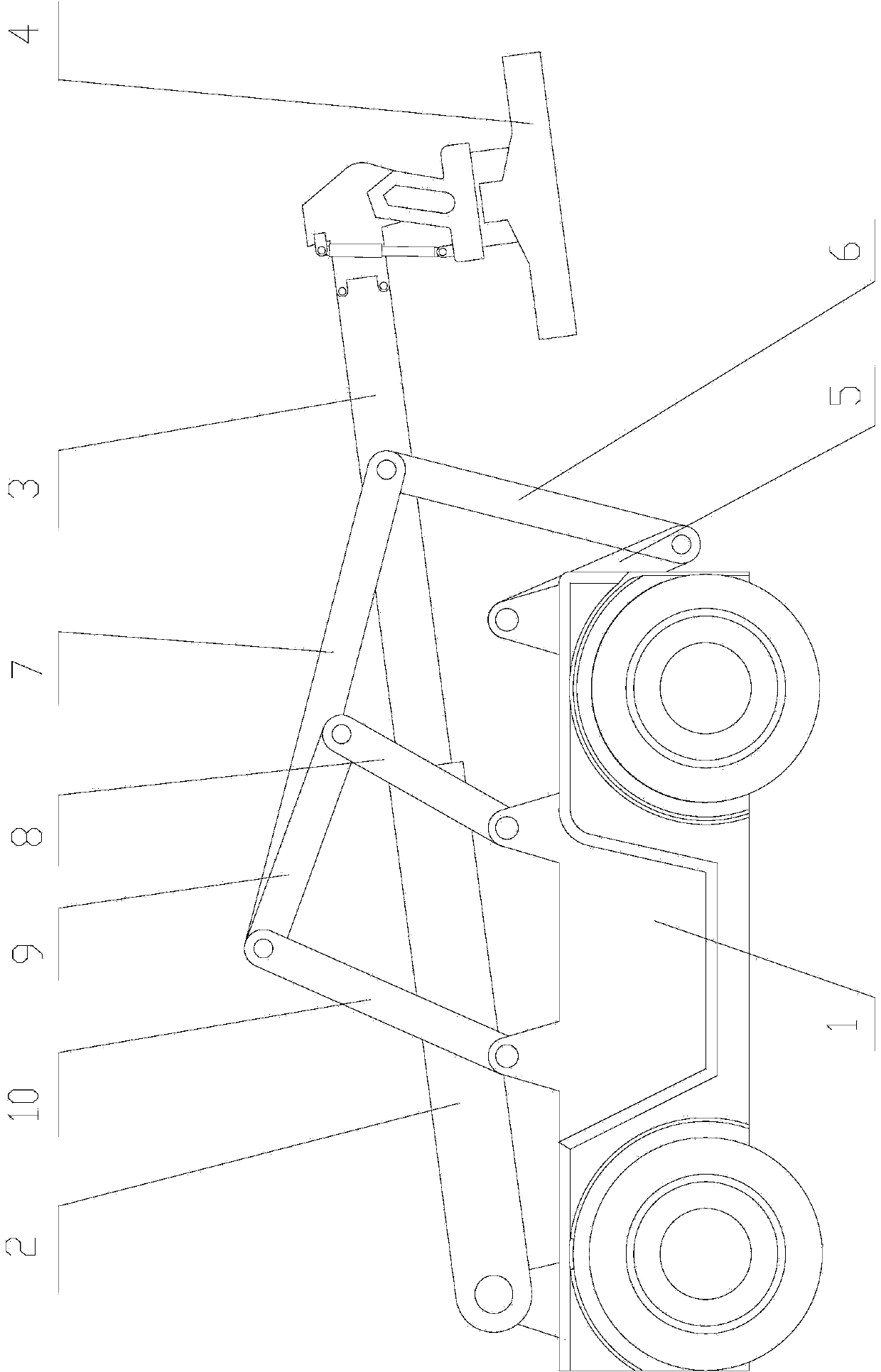

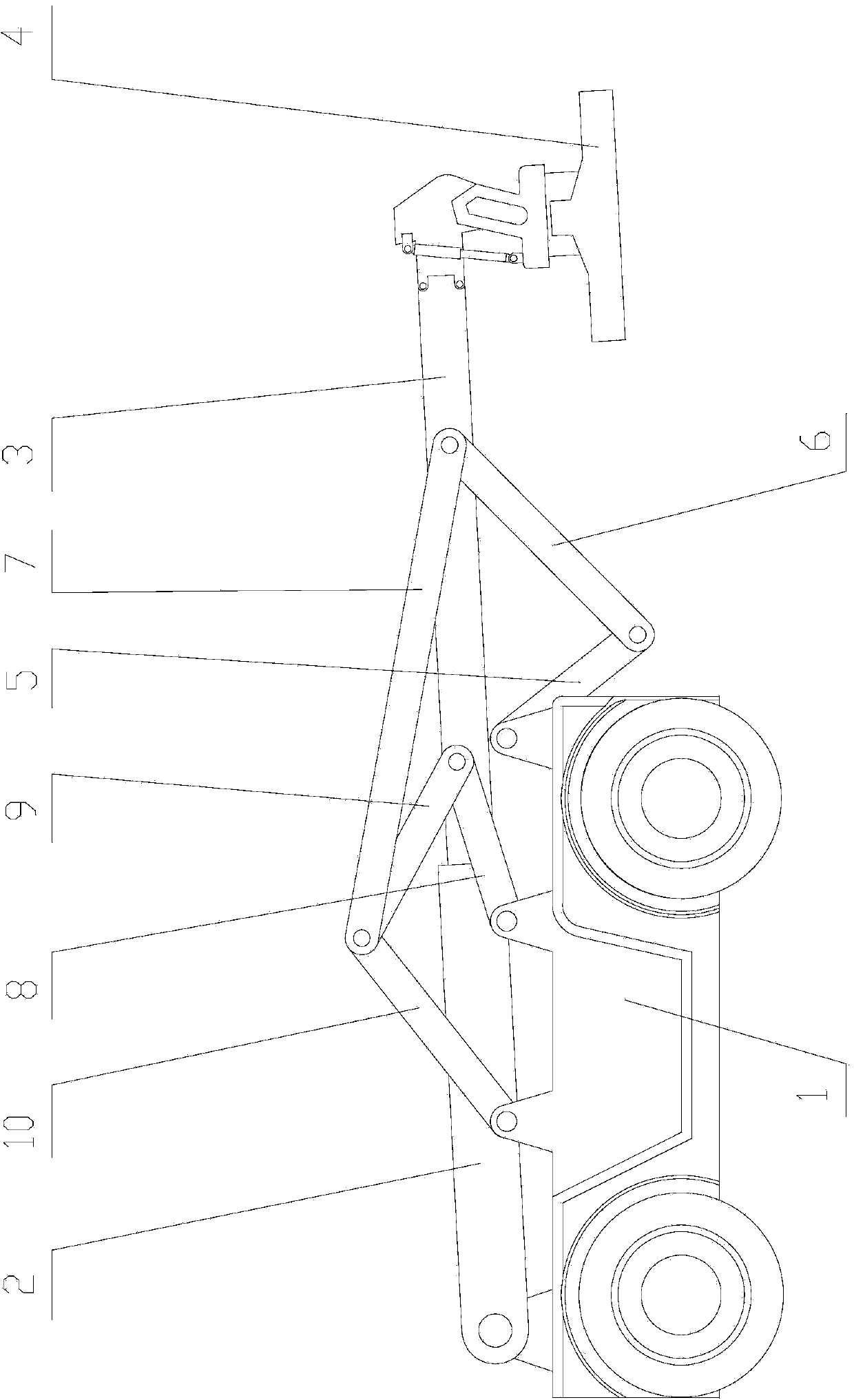

[0017] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0018] The plane two-degree-of-freedom nine-rod closed-chain container front-handling crane of the present invention includes a boom provided on the basis of a vehicle frame 1 and a boom elevating and telescoping mechanism.

[0019] The boom includes a rotating arm 2 and a telescopic arm 3, the lower end of the rotating arm 2 is hinged at the rear of the vehicle frame 1, and the telescopic arm 3 is mounted on the rotating arm 2 through a sliding pair, in a specific way Among them, both the rotating arm 2 and the telescopic arm 3 are made of square steel pipes, and the telescopic arm 3 slides and fits inside the rotating arm 2 at the upper opening of the rotating arm 2, and the clamping device 4 for grabbing the container is arranged at the front end of the telescopic arm 3, Such as figure 1 shown.

[0020] The lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com