Filtering apparatus for edible oil pre-squeezing technology

A filter cavity and cylinder technology, which is applied in the field of continuous production of edible oil processing and pre-pressing process, can solve the problems of unclean filtering of fine solid particles, abnormal operation of crude oil pump, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

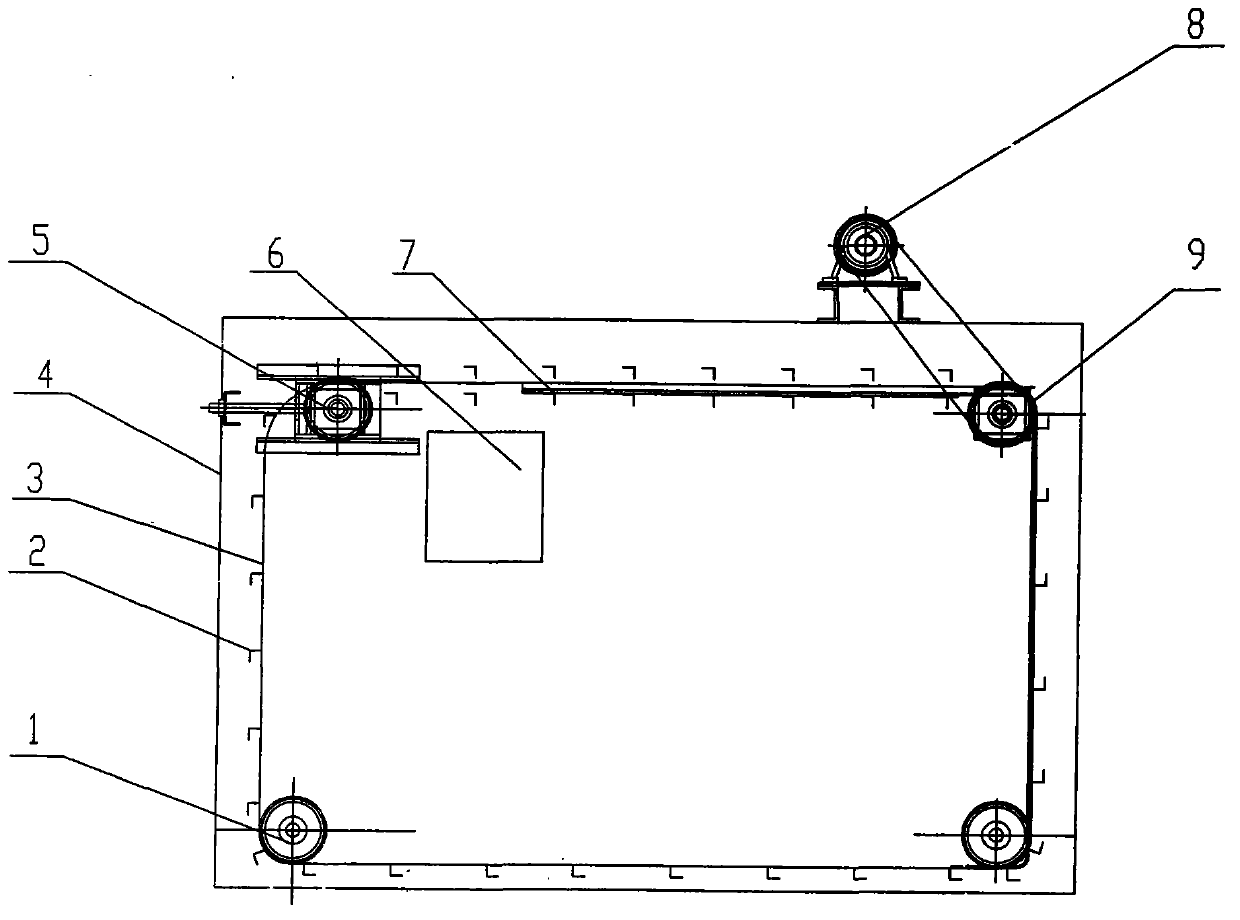

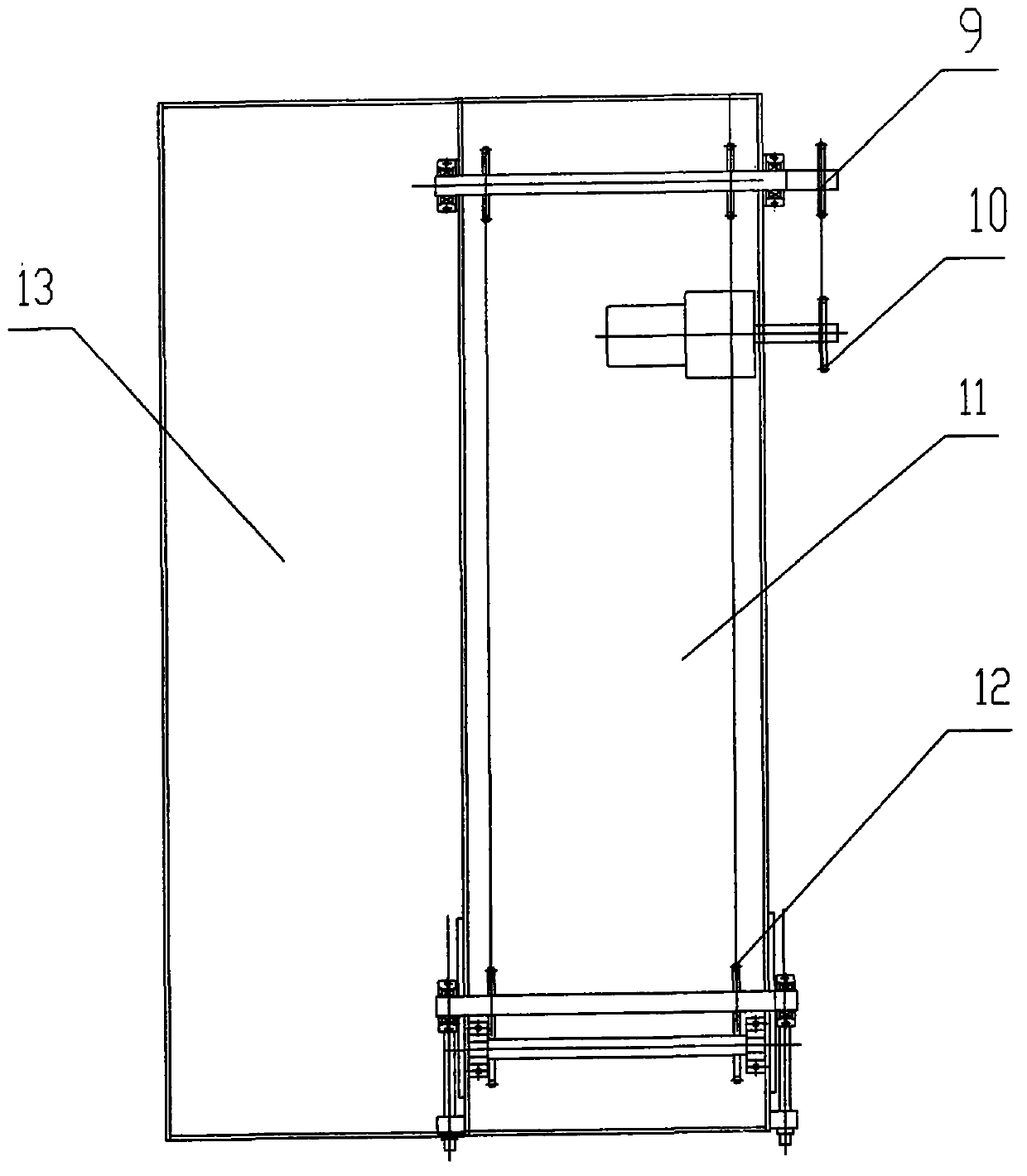

[0009] The products involved in this project, such as figure 2 As shown, the cylinder is divided into two connected chambers through the partition, the filter chamber 11 and the settling chamber 13; the turbid crude oil from the transport enters the filter chamber 2, and when the solid particles reach a certain height after precipitation, such as figure 1 The shown motor reducer 8 adopts a chain transmission mode to drive the driven sprocket 9 at an ultra-low speed; so that the solid particles fall into the groove of the scraper, and when the solid particles are transported to the filter plate 7 through the transmission of the chain, due to the design of the sieve plate 7 There are gaps; due to the slow running speed of the chain 3, the solid particles containing edible oil are separated from the oil residue; the edible oil falls into the filter chamber 11, and the oil residue is discharged from the discharge port 6 and transported to the oil press by other conveying equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com