Oil dipstick tube plugging mechanism

An oil dipstick and pipe sealing technology, which is used in pipe components, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of troublesome sealing experiments, unsatisfactory results, and no blocking mechanism, and achieves convenient operation and blocking. The effect of tight and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

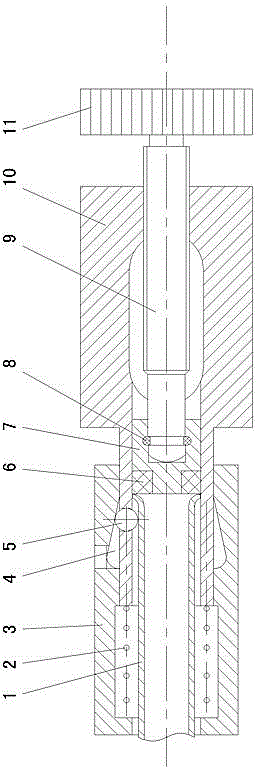

[0008] Such as figure 1 Shown: 1 is the oil dipstick tube of automobile engine. This mechanism includes a front cover body 3 and a rear cover body 10. The front part of the rear cover body 10 is inserted into the hole of the front cover body 3, and a spring 2 is arranged between the front end of the rear cover body 10 and the inner end surface of the front cover body 3. , the inner side of the rear part of the front cover body 3 is processed with an annular groove 4, the annular groove 4 is located on the outer side of the front part of the rear cover body 10, the diameter of the annular groove 4 gradually decreases from the front end to the rear end, and there is a hole in the front part of the rear cover body 10 , the steel ball 5 is located in the hole, the inner hole of the rear sleeve body 10 is threadedly connected with the screw rod 9, the front end of the screw rod 9 is connected with the indenter 7 through the snap ring 8, and the indenter 7 is set on the front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com