Automatic checkweigher with balance fine adjustment architecture

An automatic detection and balancing technology, applied in the direction of special scales, detailed information of weighing equipment, measuring devices, etc., can solve problems such as inconvenient operation, underweight, overweight, and affecting weighing accuracy, so as to improve maintenance efficiency and convenience The effect of level adjustment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

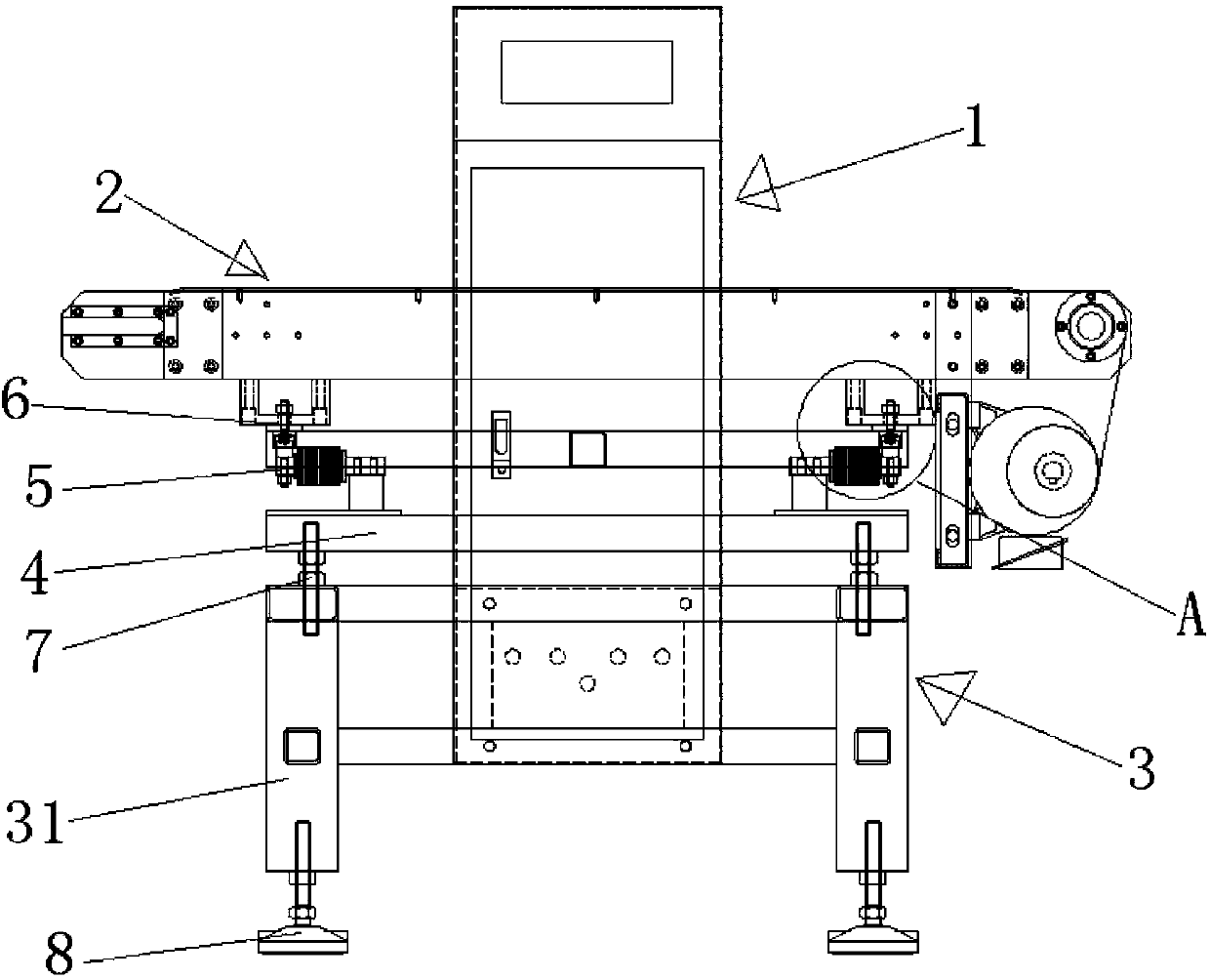

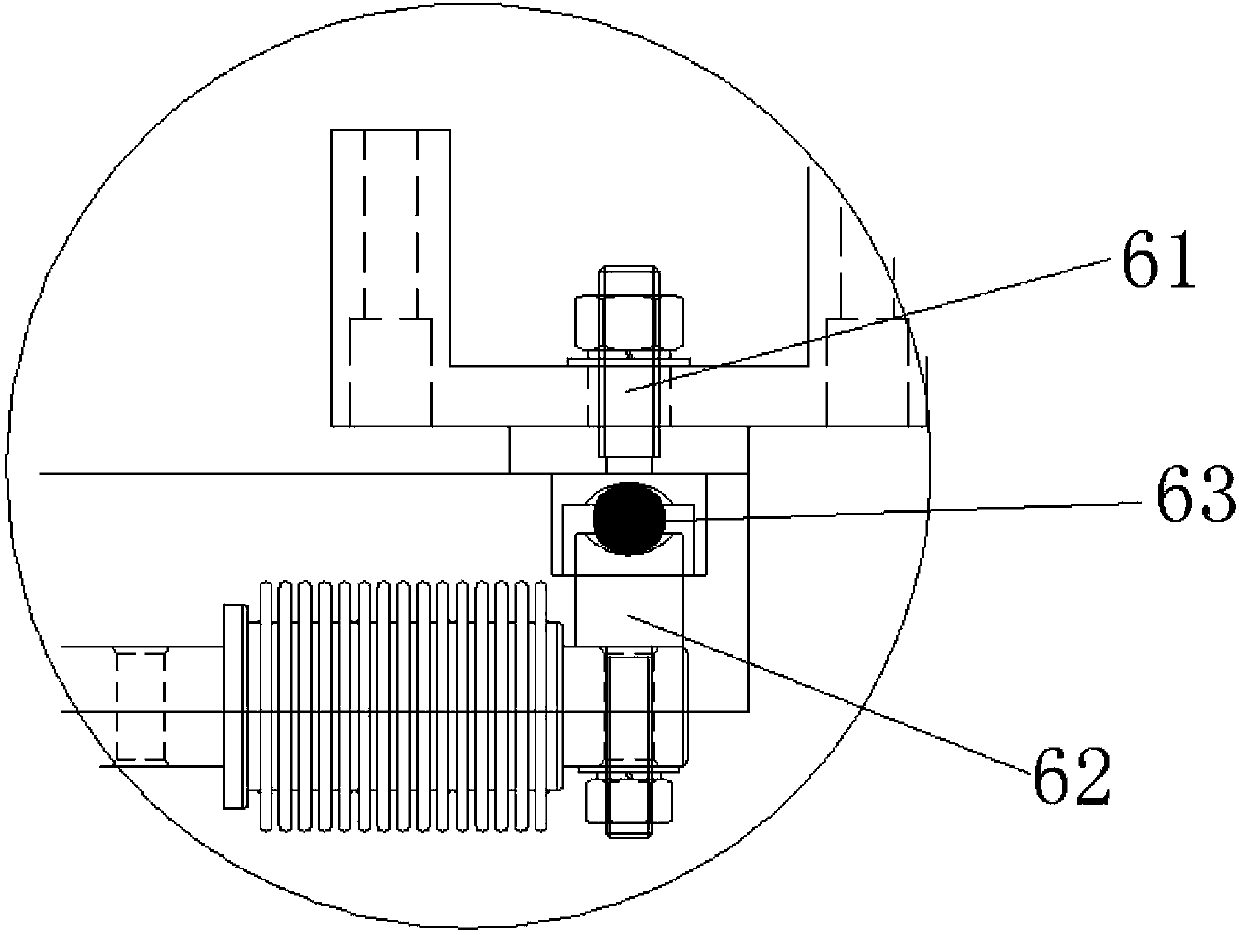

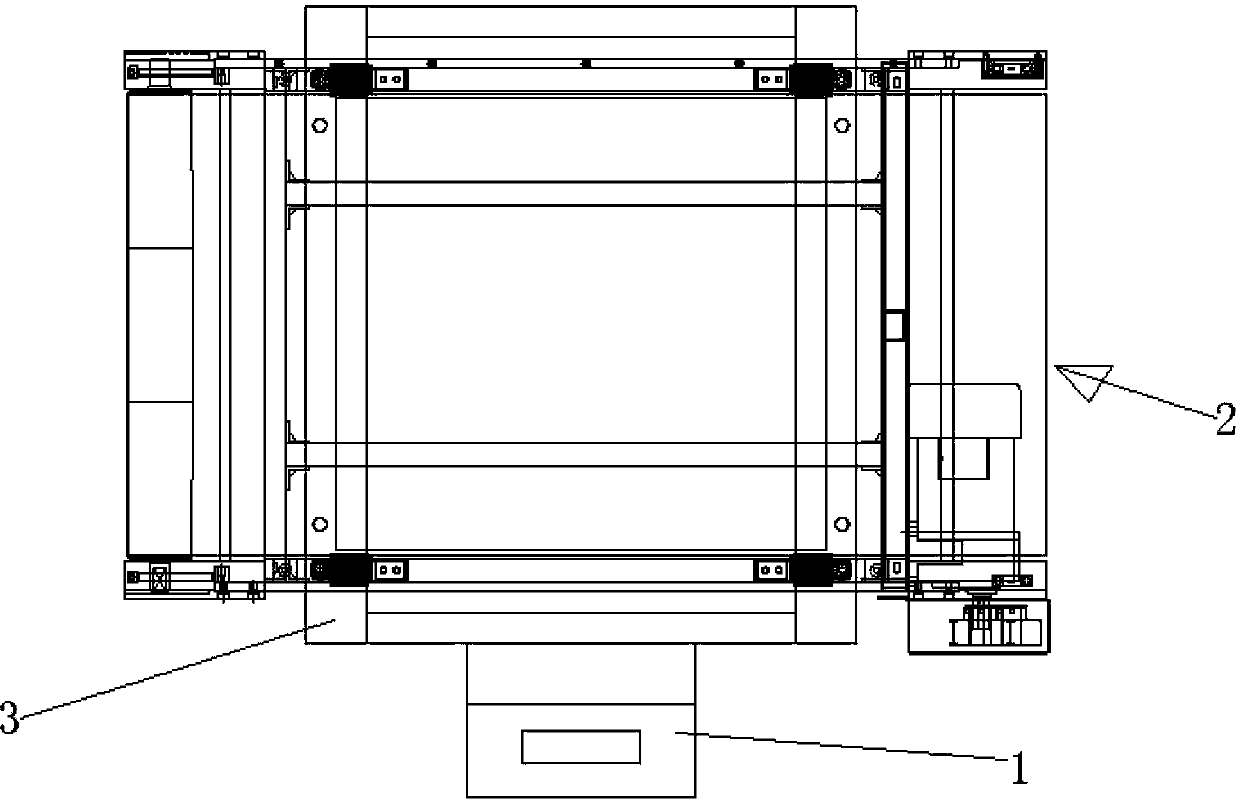

[0022] Such as figure 1 , figure 2 and image 3 As shown, an automatic checkweigher with a balance fine-tuning structure includes an electric box 1, a weighing platform 2 and a frame 3, the weighing platform is horizontally located on the frame, and the electric box is located on the weighing platform. One side of the heavy platform, and fixedly connected with the frame, a balance fine-tuning structure 4 is provided between the frame and the weighing platform, and a balance fine-tuning structure 4 is provided on the side facing the weighing platform. Several load cells 5, the load cells and the weighing table are positioned and connected through the reset mechanism 6, and the load cells are electrically connected to the electric box, and the balance fine-tuning structure can horizontally adjust the scale In this way, the level of the weighing platform can be adjusted more precisely through the balance fine-tuning structure, making the level adjustment of the weighing platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com