Impact test table based on axial loading of wind power high-speed shaft bearing

An axial loading and impact test technology, applied in impact testing, mechanical bearing testing, machine/structural component testing, etc., can solve the problems of inability to simulate bearing impact load, complex implementation of bearing axial loading device, and high cost. The effect of low cost, simple installation and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

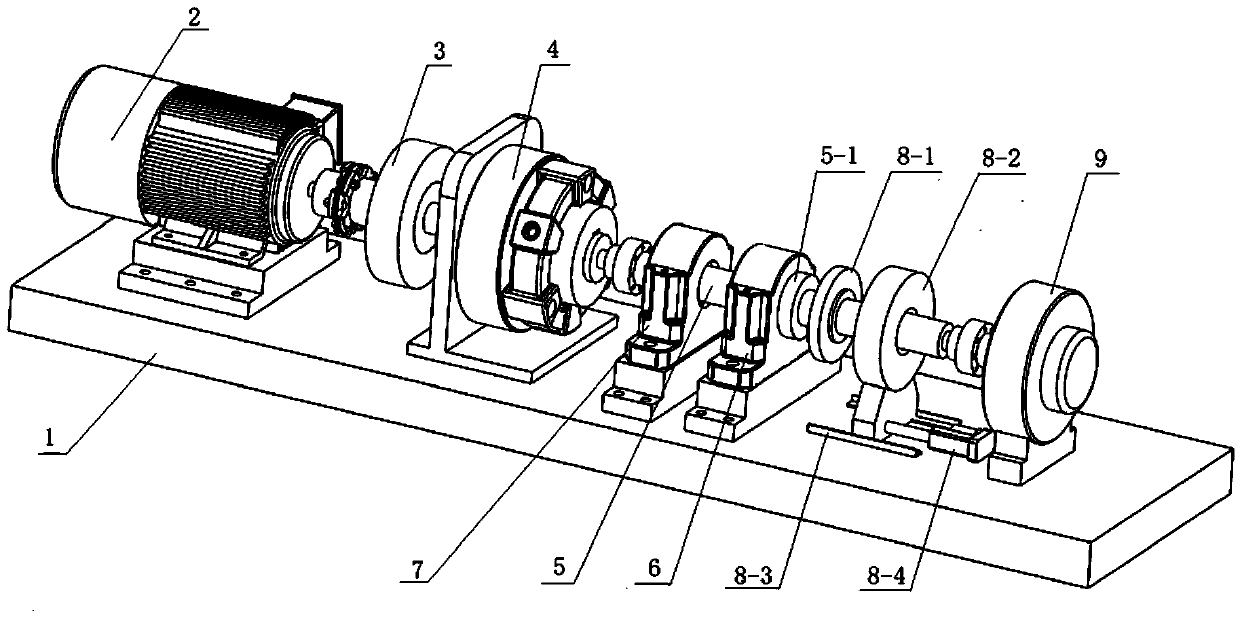

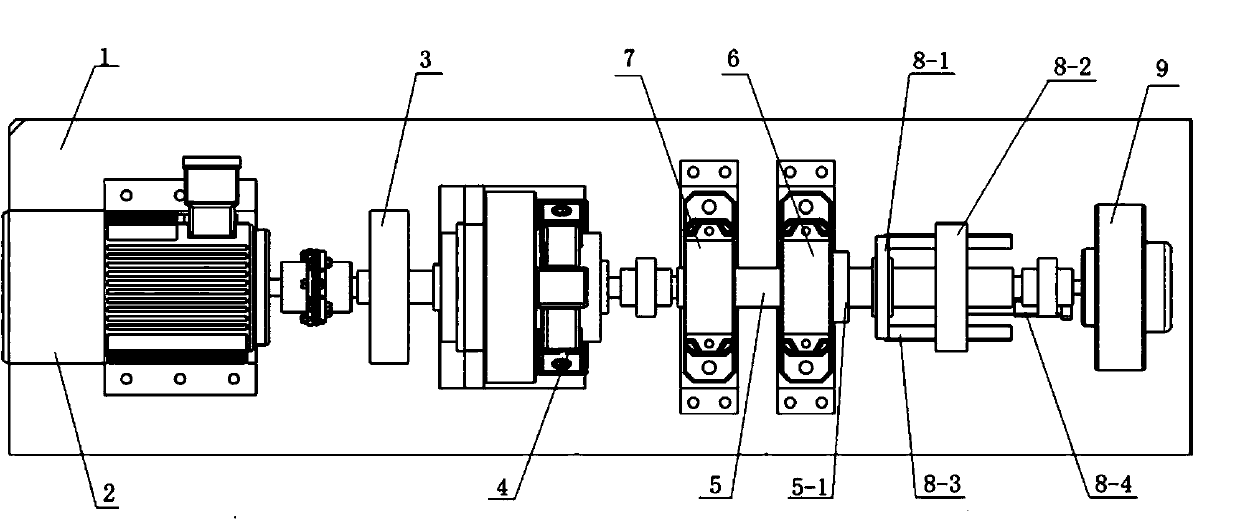

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] refer to figure 1 and figure 2 , an impact test bench based on the axial loading of wind power high-speed shaft bearings, including a base table 1, a driving motor 2, a flywheel 3, a clutch 4, a rotating main shaft 5, a main test bearing 6, an accompanying test bearing 7, and an axial loading device 8 and magnetic powder brake 9,

[0018] The driving motor 2 is a three-phase variable frequency speed regulating motor, which is used as the rotating drive source of the test bench. The motor is selected from Anhui Wannan Motor, model YVF2-90S-4, with a rated power of 1.1kW, a rated speed of 1500rpm, and a frequency conversion range of 5-100Hz , the driving motor 2 is installed on one end of the base platform 1, the output shaft of the driving motor 2 is connected with one end of the central shaft of the flywheel 3 through a diaphragm coupling, the clutch 4 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com