System and method for detecting instantaneity of industrial control system

A technology of industrial control system and detection system, applied in the direction of electrical testing/monitoring, etc., can solve the problem of low accuracy and achieve the effect of overcoming real-time evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned objectives, features and advantages of the present invention more obvious and understandable, the technical solutions of the present invention will be further detailed in conjunction with the accompanying drawings. Description.

[0024] The present invention provides a system and method for detecting the real-time performance of an industrial control system, which can specify a specific range of the industrial control system, or a specific process control loop for measuring delay time and real-time performance, and can effectively evaluate the quality of the industrial control system.

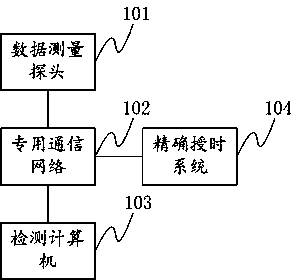

[0025] A real-time detection system for industrial control systems, including:

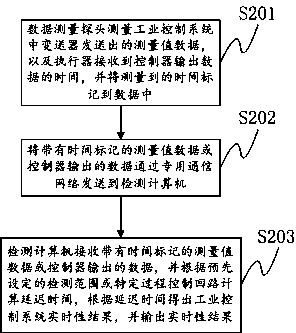

[0026] The data measuring probe 101 is used to measure the measured value data sent by the transmitter in the industrial control system, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com