Cloud service-based intelligent production system and implementation method

A technology of intelligent production and implementation methods, applied in the fields of instruments, data processing applications, logistics, etc., can solve the problems of inability to understand real-time production information, increase the cost of enterprise personnel, information lag, etc., and achieve automatic production and real-time data access and control. , the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

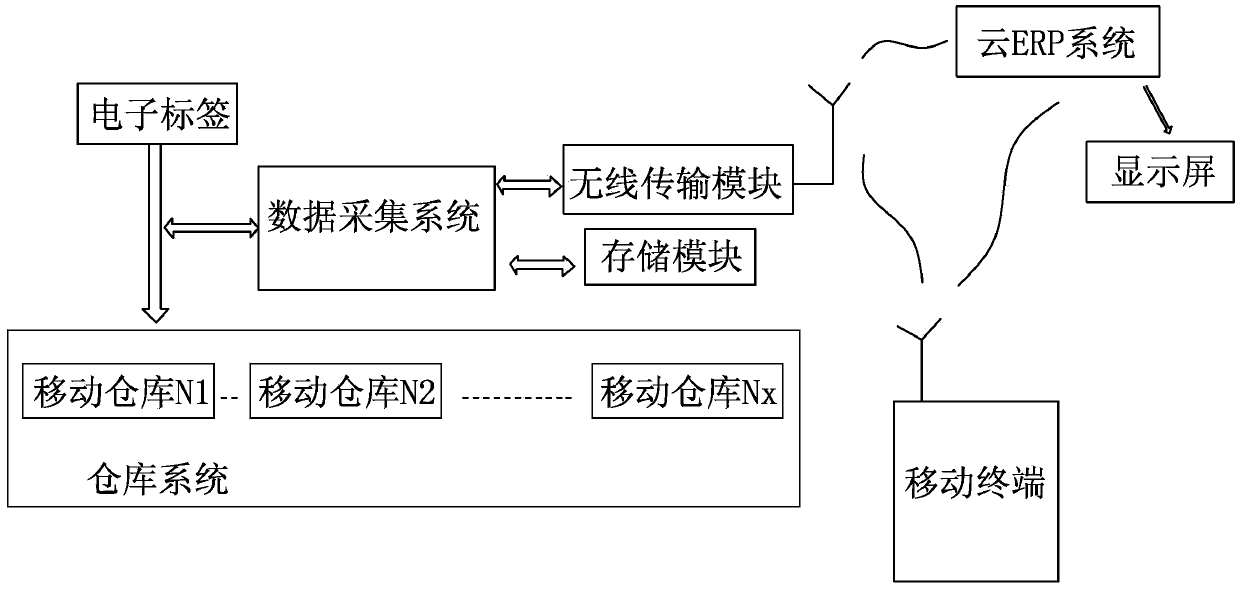

[0020] See figure 1 , is a schematic diagram of the basic principle of the present invention. The present invention includes an electronic label, a data acquisition system, a warehouse system, a cloud ERP system, and a display screen. The warehouse system matches the electronic label. The warehouse system includes a plurality of mobile warehouses, and the data acquisition system collects the electronic labels. The data information is transmitted to the cloud ERP system, and the cloud ERP system is connected to the display screen.

[0021] The data acquisition system can be a FRID, QR code or barcode data acquisition system.

[0022] The data acquisition system is connected to the wireless transmission module and the storage module.

[0023] The cloud ERP system is wirelessly connected to the mobile terminal, and the mobile terminal has an application program for data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com