Membrane surface windowing process for solar cell

A technology of solar cell and window opening technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high initial investment cost of laser equipment, high operating cost of corrosion slurry, etc., and achieve high-efficiency gas corrosion rate, high production capacity, and process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

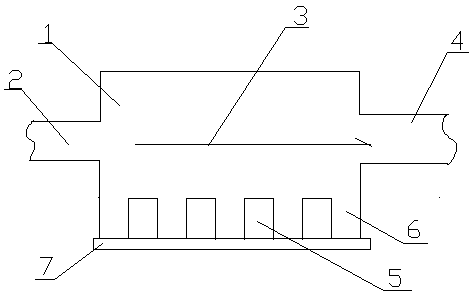

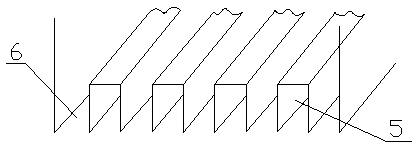

[0012] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention uses the silicon chip 7 coated with SiO2 (or SiNx / Al2O3 / a-Si and other thin films that can play passivation and anti-reflection effects) film. The corrosive gas enters the cavity 1 from the inlet pipeline 2 and comes out from the gas outlet pipeline 4. The gas inlet pipeline 2 and the gas outlet pipeline 4 can be connected and recycled according to the process requirements or not. Such as figure 1 As shown, the window position 6 in the cavity 1 needs to communicate with the internal gas, while the position of the vacuum pipeline 5 is isolated from the cavity 1, and the corrosive gas directly contacts the film surface of the coated silicon wafer 7 through the window position 6 to achieve To react with the membrane surface to remove the membrane surface, the vacuum line 4 sucks the silicon wafer 7 by introducing negative pressure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com