Automatic punching equipment

A technology for automatic punching and punching, applied in the field of automatic punching equipment, can solve the problems of unstable riveting between the lamp head and the lamp body, the production quality cannot be guaranteed, and the distance between punching points is easy to leak, so as to achieve high-quality production and stable riveting. , The effect of solving the leakage point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

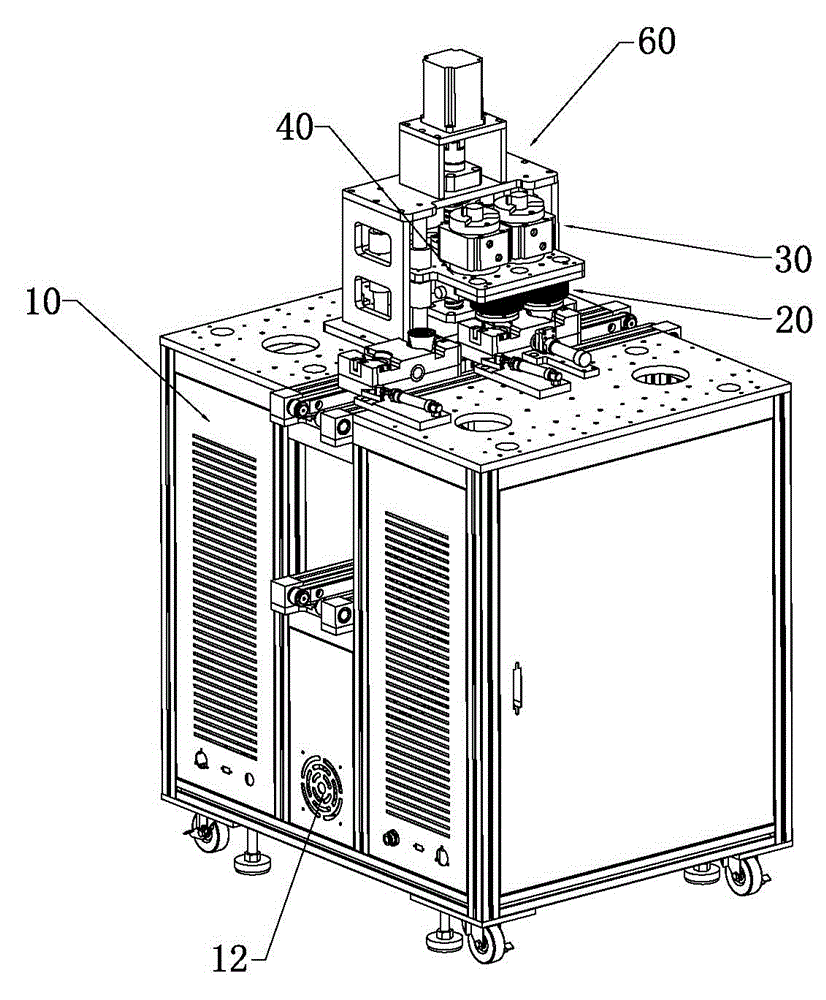

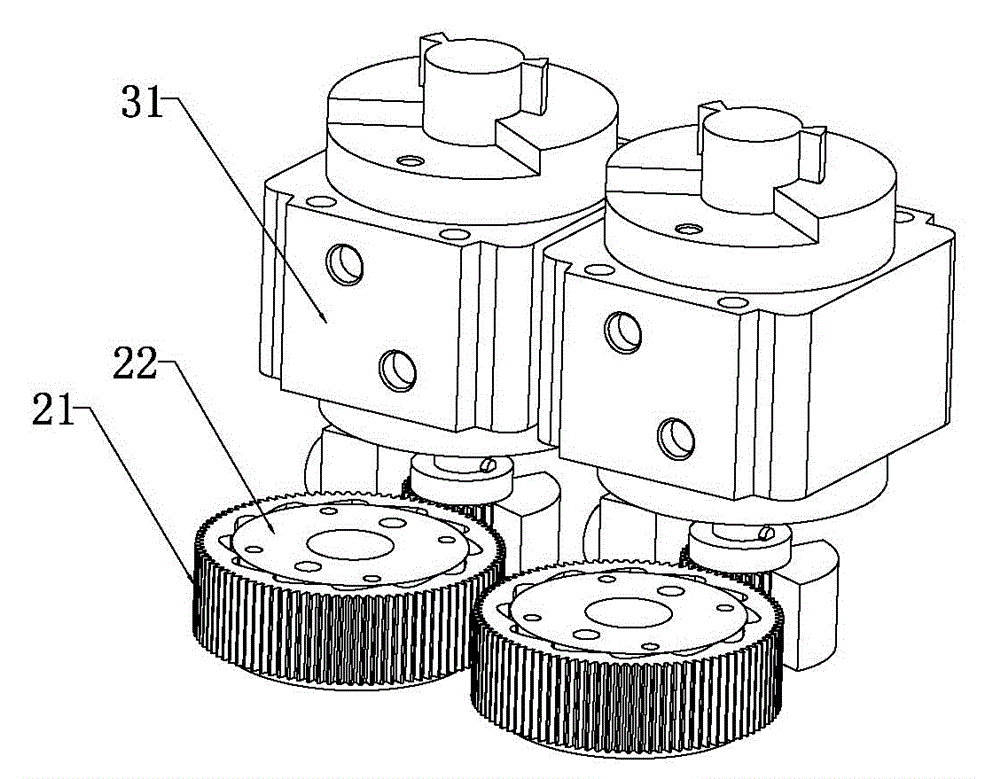

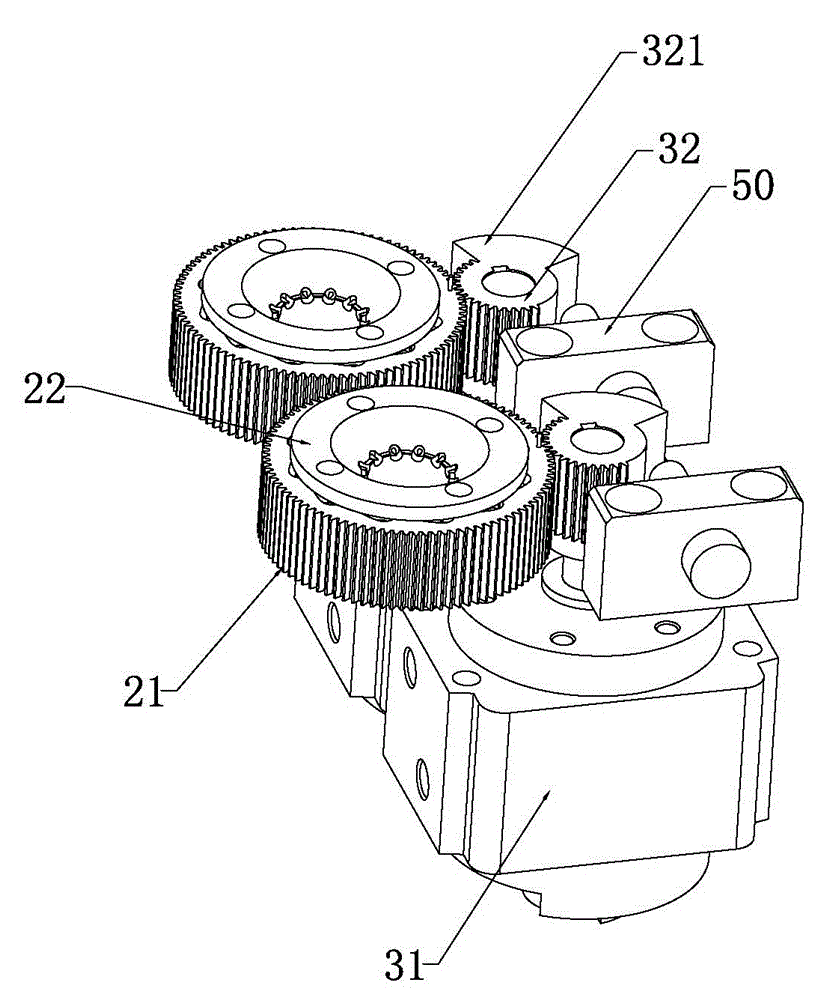

[0040] Such as Figure 1 to Figure 12 As shown, the automatic punching equipment of the present invention includes a chassis 10, a punching device 20 is arranged above the cabinet 10, and the punching device 20 includes a punching wheel 21 and a punching sleeve 22, and the top of the cabinet 10 is provided with a The power mechanism 30 that the punching wheel 21 rotates forward and backward, the punching sleeve 22 is arranged in the punching wheel 21, the punching sleeve 22 is provided with several punching needles 23 in a circular radial shape, and the punching needle 23 covers are provided with elastic The element 24 ; the inner edge of the punching wheel 21 is provided with a rolling surface 211 that pushes the punching needle 23 to move radially when the punching wheel 21 rotates, and the outer end of the punching needle 23 abuts against the rolling surface 211 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com