Large-breadth seamless splicing method and system for laser processing

A technology of seamless surface splicing and laser processing, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of affecting processing efficiency, galvanometer empty running, discontinuous processing pattern, etc., to improve efficiency, Guaranteed quality and speed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

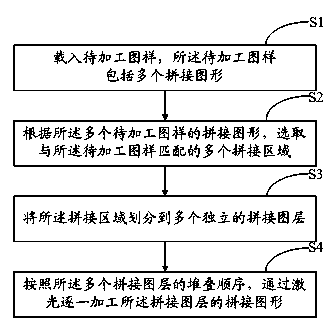

[0037] Such as figure 1 As shown, in one embodiment of the present invention, the method for large-format seamless splicing for laser processing includes the following steps:

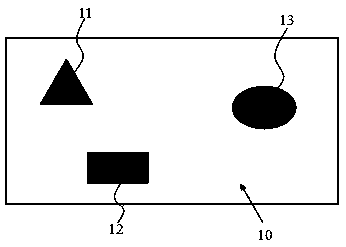

[0038] S1. Load the pattern to be processed, the pattern to be processed includes a plurality of spliced graphics.

[0039] Specifically, the pattern to be processed that needs to be identified is loaded, and the pattern to be processed includes a plurality of mosaic patterns. The type of the mosaic pattern is not specifically limited, and may include one type of mosaic pattern or multiple types of mosaic patterns. There is no specific li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com