A tool for automatic welding of thick-walled hollow rods

An automatic welding and hollow rod technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as length dimensional tolerance, achieve the effect of compensating length dimensional tolerance, improving work efficiency, and improving the degree of welding automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

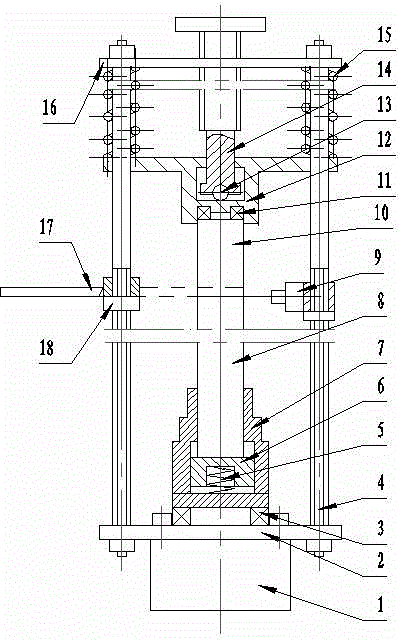

[0011] A tooling for automatic welding of thick-walled hollow rods, consisting of a servo motor 1, a lower support plate 2, a lower thrust bearing 3, a column 4, a lower compensation spring 5, a spring sleeve 6, a three-jaw chuck 7, and a long hollow rod 8. Welding gun assembly 9, short hollow rod 10, upper thrust bearing 11, floating pressure sleeve 12, steel ball 13, screw rod 14, upper compensation spring 15, upper support plate 16, positioning plate assembly 17, limit nut 18 It is composed of 18 links.

[0012] Among them, the upper support plate 16, the lower support plate 2 and the column 4 are used as the basic frame for the installation of each link of the tooling, and are also the load-bearing frame for axially clamping the weldment. The servo motor 1 is located at the bottom of the lower support plate 2, and one end of the long hollow rod 8 is connected to the servo motor 1 through the three-jaw chuck 7, and the servo motor 1 drives the three-jaw chuck 7 and the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com