A control method for front and rear blocking of electric locomotive train tubes

A control method and technology for electric locomotives, applied in the direction of hydrostatic brakes, hydrodynamic brakes, pneumatic brakes, etc., can solve the problems of asynchronous brake relief, incomplete train braking, and abnormal discharge of relay valves for heavy-duty machines. Wind and other issues to achieve the effect of ensuring braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

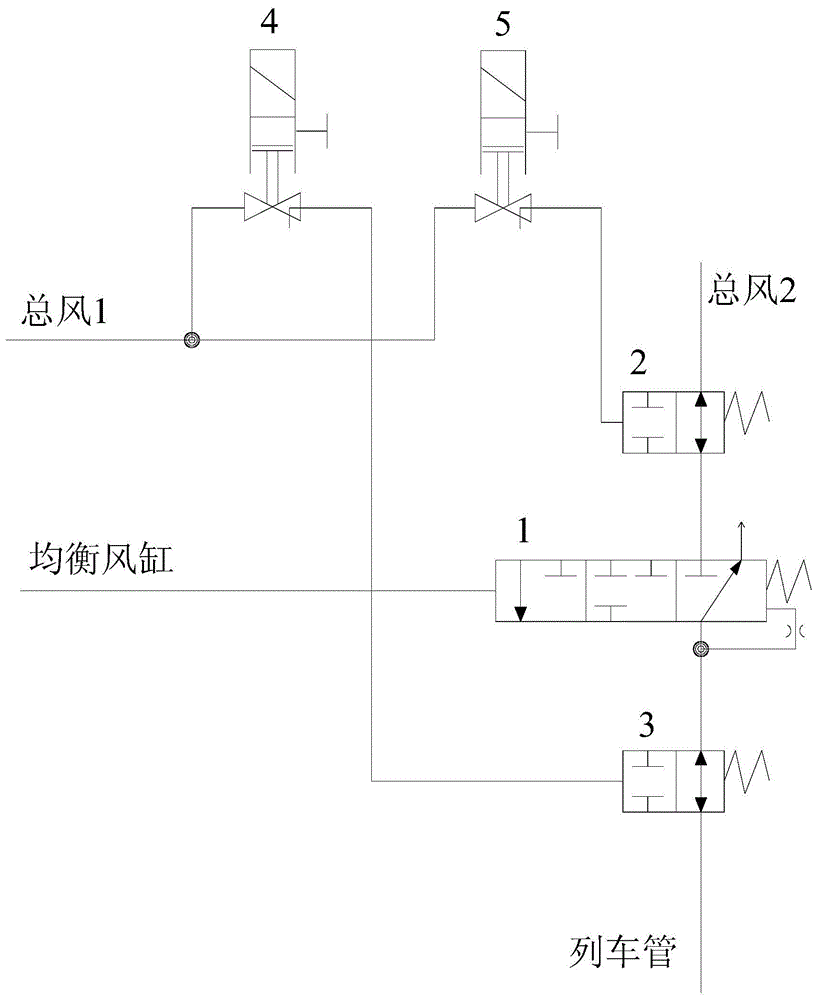

[0022] The core of the invention lies in disclosing a control method for front and rear blocking of train pipes of electric locomotives, which can accurately and reliably control the air filling and exhausting actions of train pipes of electric locomotives.

[0023] For ease of understanding, the technical terms involved in this solution are explained as follows:

[0024] Total air source: from the main air cylinder, which stores the compressed air generated by the air compressor, and all places on the vehicle that need compressed air must use the air from the main air cylinder.

[0025] Equilibrium air cylinder: the pressure vessel directly controlled by the automatic brake valve, and through the pressure change of the equalization air cylinder, the action of the relay valve is controlled, so that the pressure of the train pipe changes accordingly.

[0026] Relay valve: the purpose is to transfer the compressed air from the main air source to the train pipe to pressurize it; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com