Packing auger speed changer

A technology of speed changer and winch cage, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. Unsteady disk tension and other problems, to save labor and materials, reduce the probability of broken wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

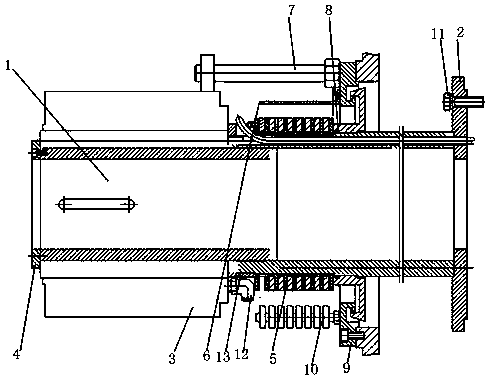

[0014] Such as figure 1 As shown, a kind of twisted cage speed changer according to the present invention includes a twisted cage gearbox body 1, a flange shaft 2 is installed on one end of the twisted cage gearbox body 1, and a rotary air joint 3 is installed on the other end, and through the pressure ring 4 to carry out fixed sealing, install the nine-ring combination slip ring 5 on the right side of the rotary air joint 3, install the guard cover 6 above the nine-ring combination slip ring 5, install the screw rod 7 above the guard cover 6; install the sealing washer 8 on the flange shaft 2, twist A rear cover 9 is installed on the cage gearbox body 1, and the sealing gasket 8 and the rear cover 9 form a rotary sealing package, and a capstan 10 is installed on the rotary sealing package.

[0015] The above-mentioned nine-ring combination slip ring 5 is connected with a sensor; the upper end of the flange shaft 2 is installed with an angleless bolt 11; the rotary air joint 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com