End-free reinforcing shield receiving structure and receiving method

A receiving structure and shield technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of shield tunnel staggering, high construction risk, and damage in the receiving section, and achieve good economic and social benefits. The effect of shield receiving technology and strong implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

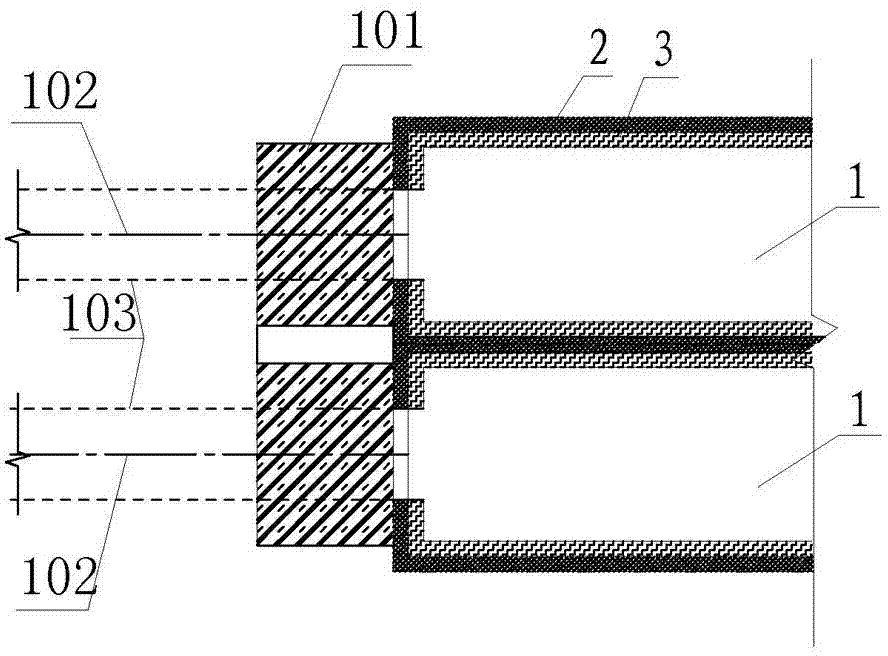

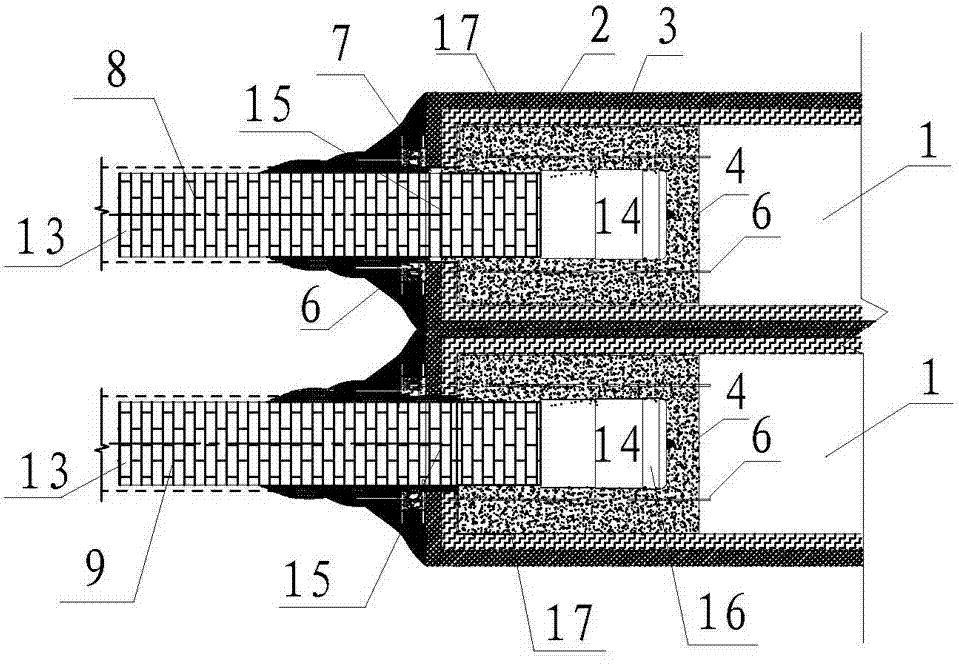

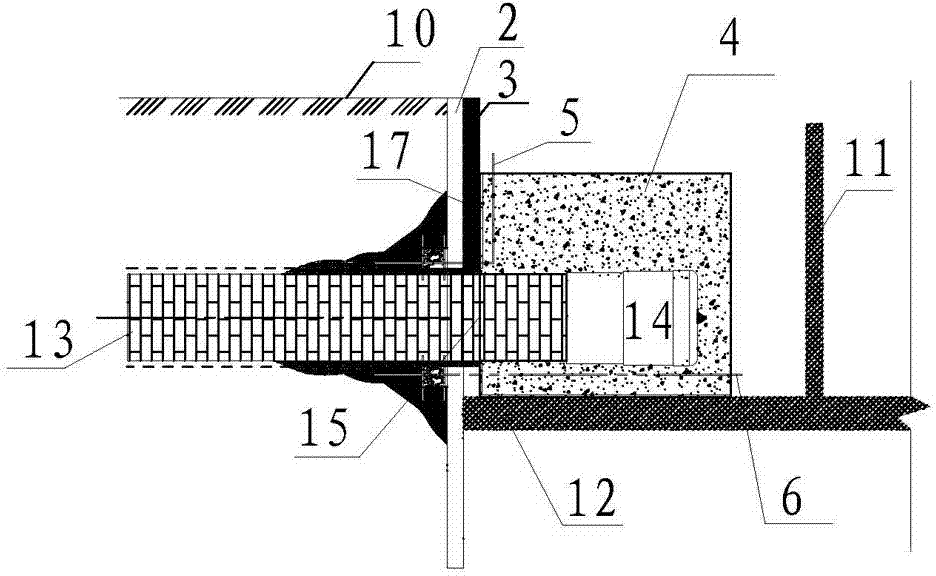

[0021] Such as figure 1 The plane plan for the reinforcement of the receiving end of the conventional shield cannot be implemented if the underground pipelines are dense, or the traffic and other factors remain unchanged, such as figure 2 , 3 As shown, it is the receiving structure of the shield without end reinforcement of the present invention, which includes a shield receiving shaft 1 with a receiving shaft enclosure structure 2 and a receiving shaft structural wall 3 two-layer enclosure arranged on the outside of the two openings 7, and the receiving shaft The structural wall 3 is inside the receiving well enclosure structure 2, and it is characterized in that: the cover hole 7 in the shield receiving well 1 is poured with a cube-shaped plain concrete block 4, and the strength label of the plain concrete block 4 is C10. And the length of the plain concrete block 4 along the longitudinal direction of the line is the length of the shield machine 14 + 4 meters, the length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com