Gunpowder actuator unlocking device

An unlocking device and actuator technology, which is applied in the direction of weapon types, projectiles, offensive equipment, etc., can solve the problems of large volume, large power consumption, sudden change in output load, etc., and achieve simple principle, large initial locking force, and easy unlocking reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

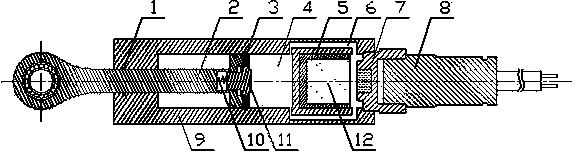

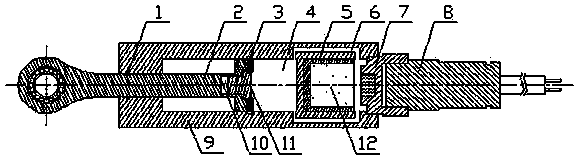

[0015] Attached below figure 1 , 2 The present invention is described in detail:

[0016] A gunpowder actuator unlocking device, which includes an actuator housing 9, a load piston 2 connected to the rear end of the actuator housing 9, and the front end of the actuator housing 9 is connected to an electric firing tube 8 through a partition 7 ; A grain column 12 is arranged in the actuator casing 9, and the grain column coating 5 is wrapped around the grain column 12;

[0017] An unlocking piston 11 is connected to the end face of the loading piston 2 through a spring 10, and the limit ball 3 is located between the outer edge of the loading piston 2 and the inner edge of the actuator housing 9; The area between them is the power chamber 4, and the air source channel 6 is between the powder coating 5 and the inner edge of the actuator shell 9;

[0018] The cross-sectional area of the end face of the unlocking piston 11 is smaller than that of the middle section of the unloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com