Oil scraper ring

A technology for oil scraping rings and working surfaces, which is applied to piston rings, engine components, mechanical equipment, etc., can solve problems such as increased wear of cylinder liners, and achieve the effects of reduced structural height, small weight, and small frictional power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

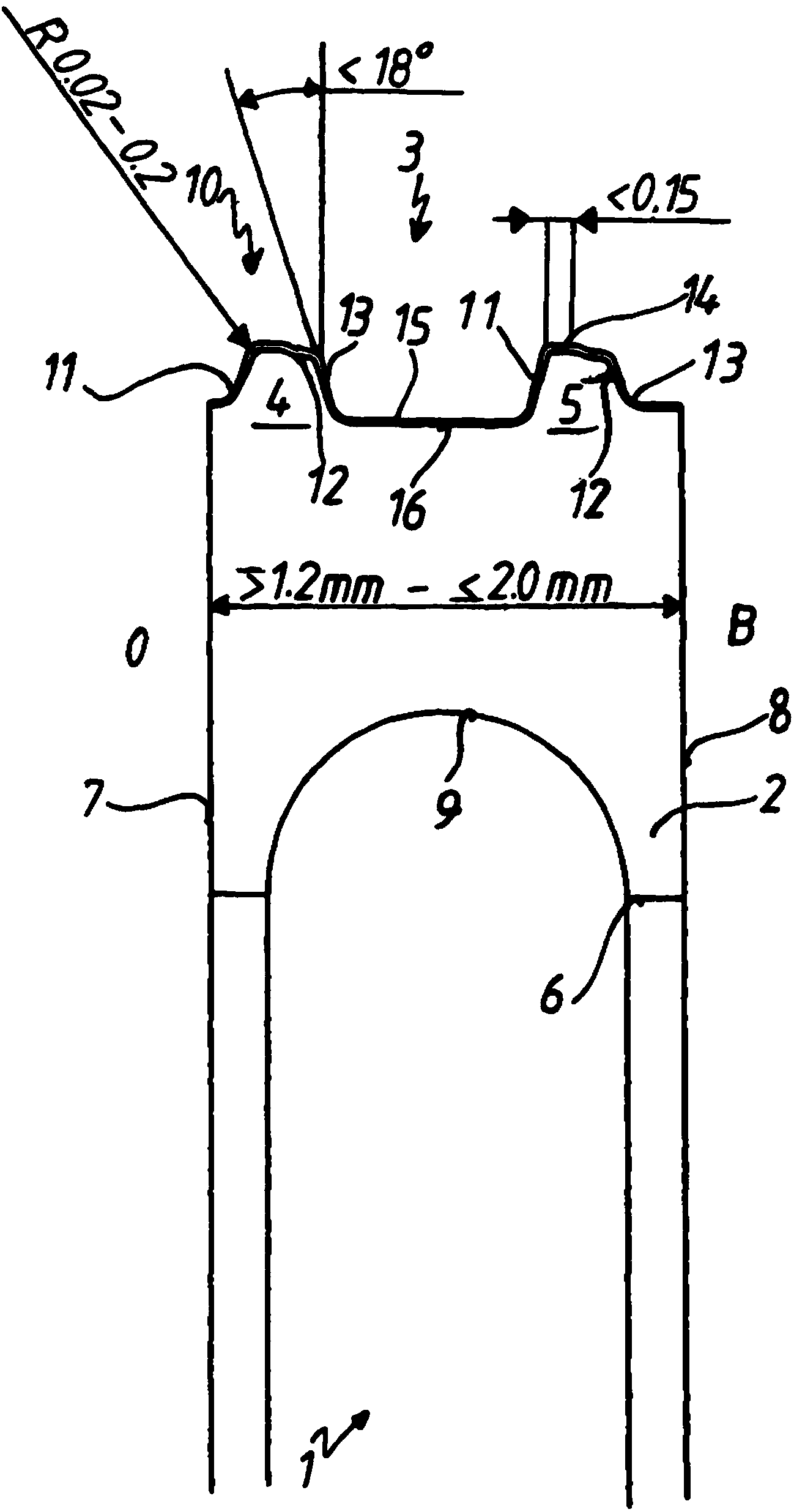

[0018] The single figure shows an oil control ring 1 with a base body 2 having a radially outer running surface 3 . The working surface lands 4 , 5 extend radially outward from the basic body 2 . Base body 2 also includes an inner peripheral surface 6 as well as a lower side 7 and an upper side 8 . The lower side 7 is assigned to the area O on the oil supply chamber side, and the side 8 is assigned to the area B on the combustion chamber side. A circumferential groove 9 is introduced in the region of the inner circumferential surface 6 for receiving a spring washer not described further. The working surface lands 4 , 5 taper radially towards their end 10 facing the corresponding working surface not further described, tapering conically from the base body 2 forming sides 11 , 13 at a side angle <18° , where the free ends 10 of the working surface lands 4, 5 are provided with a bevel 12 starting from the area O on the oil chamber side toward the area B on the combustion chambe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap