Light source apparatus and liquid crystal display apparatus

A technology of light source device and light source part, applied in the direction of light source, electric light source, point light source, etc., can solve the problem of uneven brightness, and achieve the effect of reducing the number and expanding the gap interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

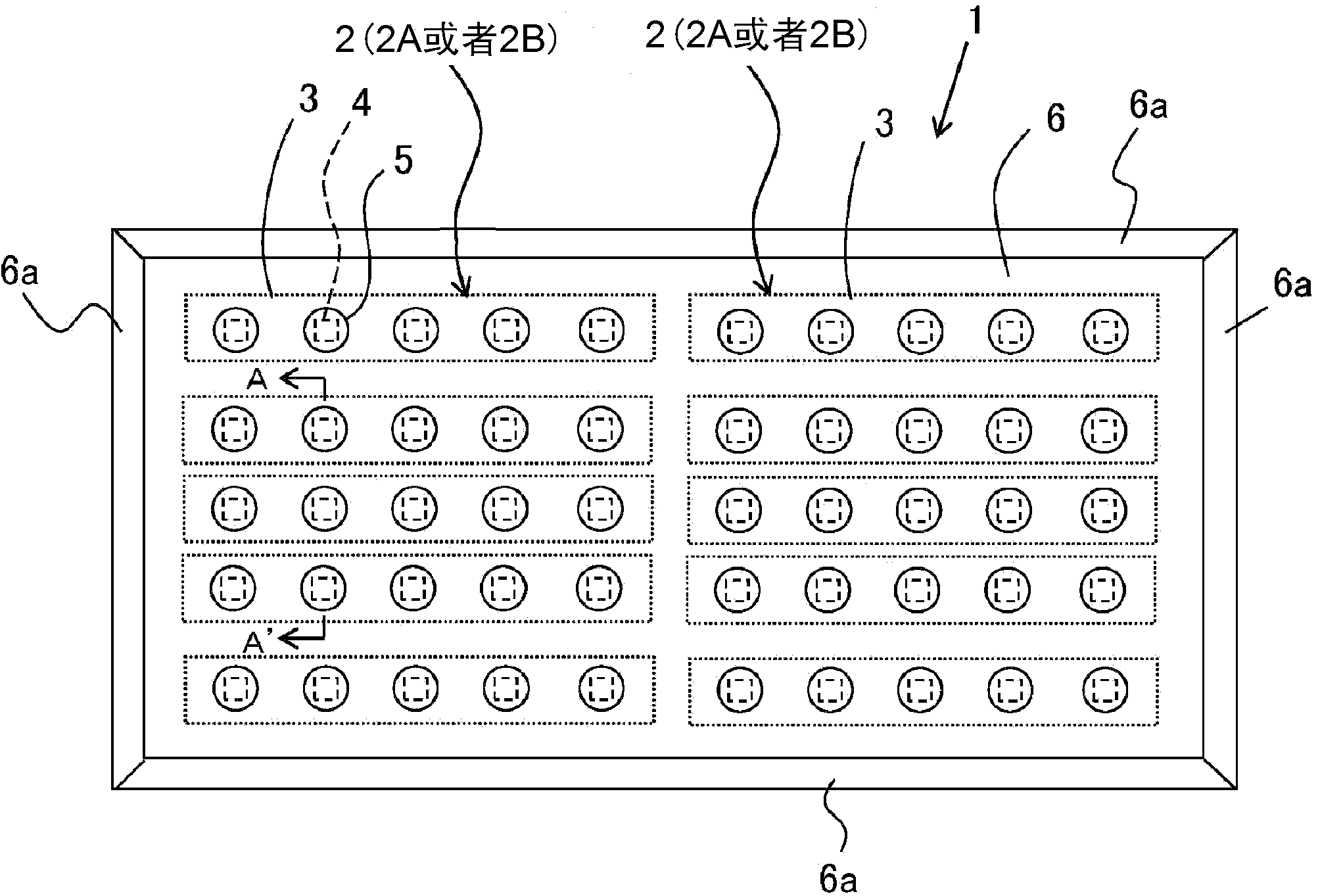

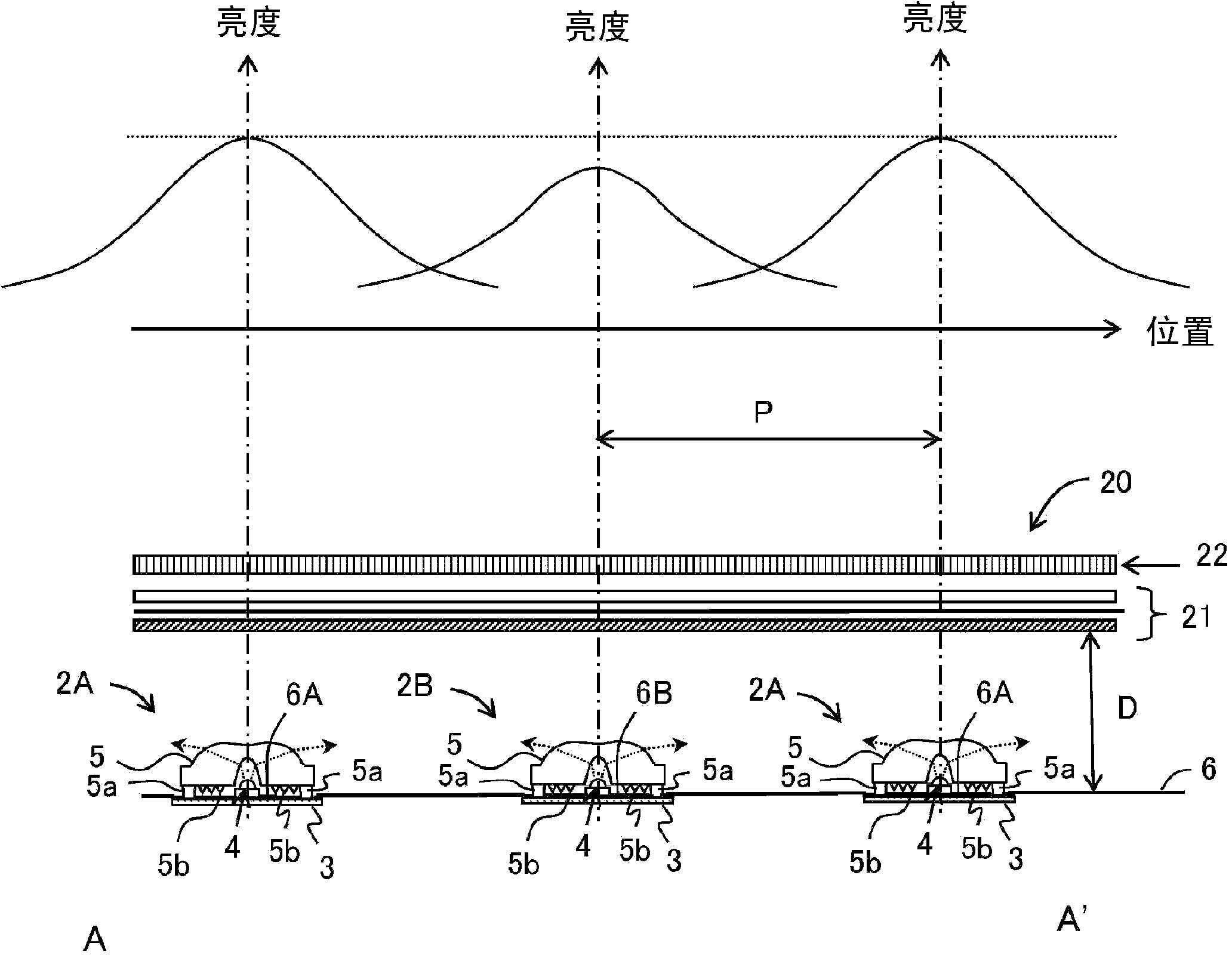

[0079] figure 1 It is a plan view schematically showing an example of the arrangement of LED modules of the LED light source device in Embodiment 1 of the present invention.

[0080] exist figure 1 Among them, the LED light source device 1 of Embodiment 1 is composed of a plurality of LED modules 2, and usually has multiple rows, but here, for convenience, five rows are arranged in the lateral direction, and each row is arranged with two rectangular modules on the left and right. In addition, among the rectangular LED modules 2 of 5 rows in the horizontal direction, in order to improve the brightness of the central part of the screen, although not explicitly shown here, the rectangular LED modules 2 of 3 rows in the center are arranged so that The longitudinal arrangement gaps are tight, and the LEDs 4 on the central side are relatively close.

[0081] Each LED module 2 has a printed wiring board surface 3, and a plurality (here, five) of LEDs 4 connected in series mounted...

Embodiment approach 2

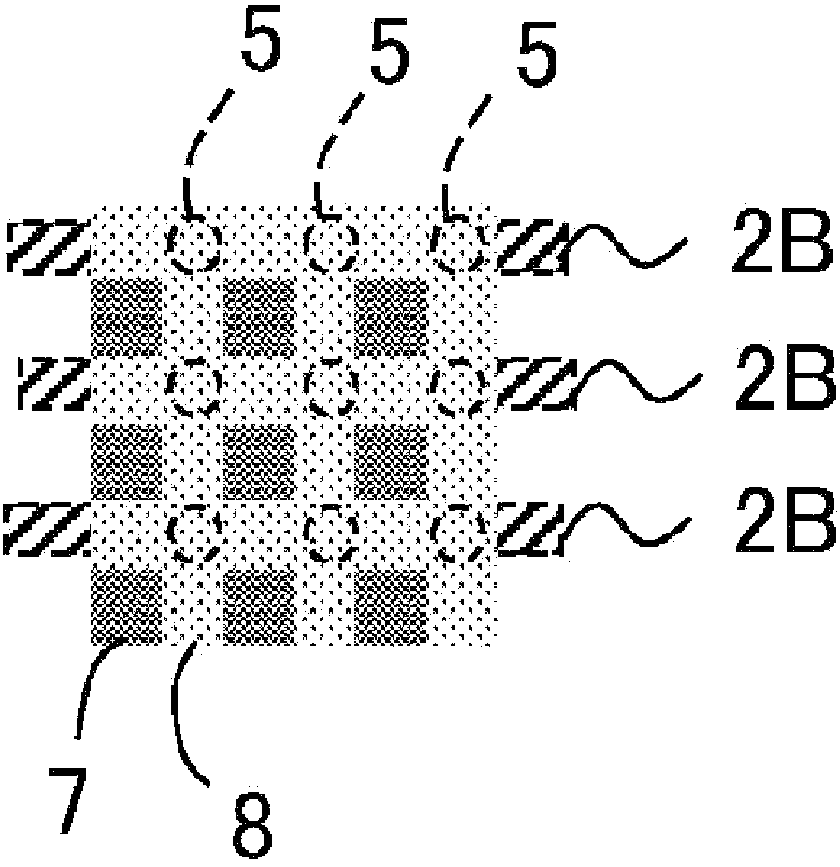

[0104] In the first embodiment described above, the case where a plurality of light source units are arranged in a matrix form in the row direction and the column direction in plan view is described, and luminance peaks are alternately arranged for each row and each column. A light source unit with a high contrast ratio between light and dark and a light source unit with a low peak brightness and a small contrast difference between light and dark are described. In the case of a high light source unit with a narrow light distribution angle (light directivity) and a light source unit with a low luminance peak and a wide light distribution angle (light directivity).

[0105] That is, compared with the case of the first embodiment described above, the point of difference is that in the first embodiment described above, the light source unit with a high luminance peak value and a large contrast difference between light and dark and the light source unit with a low peak luminance val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com