Terminal waterproofing structure of wire harness

A waterproof structure and wire harness technology, applied in the direction of connections, conductors, electrical components, etc. where permanent deformation works, can solve problems such as difficulty in improving sealing performance, difficulty in uniform pressure load, etc., to improve sealing performance, increase contact area, prevent The effect of misplacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

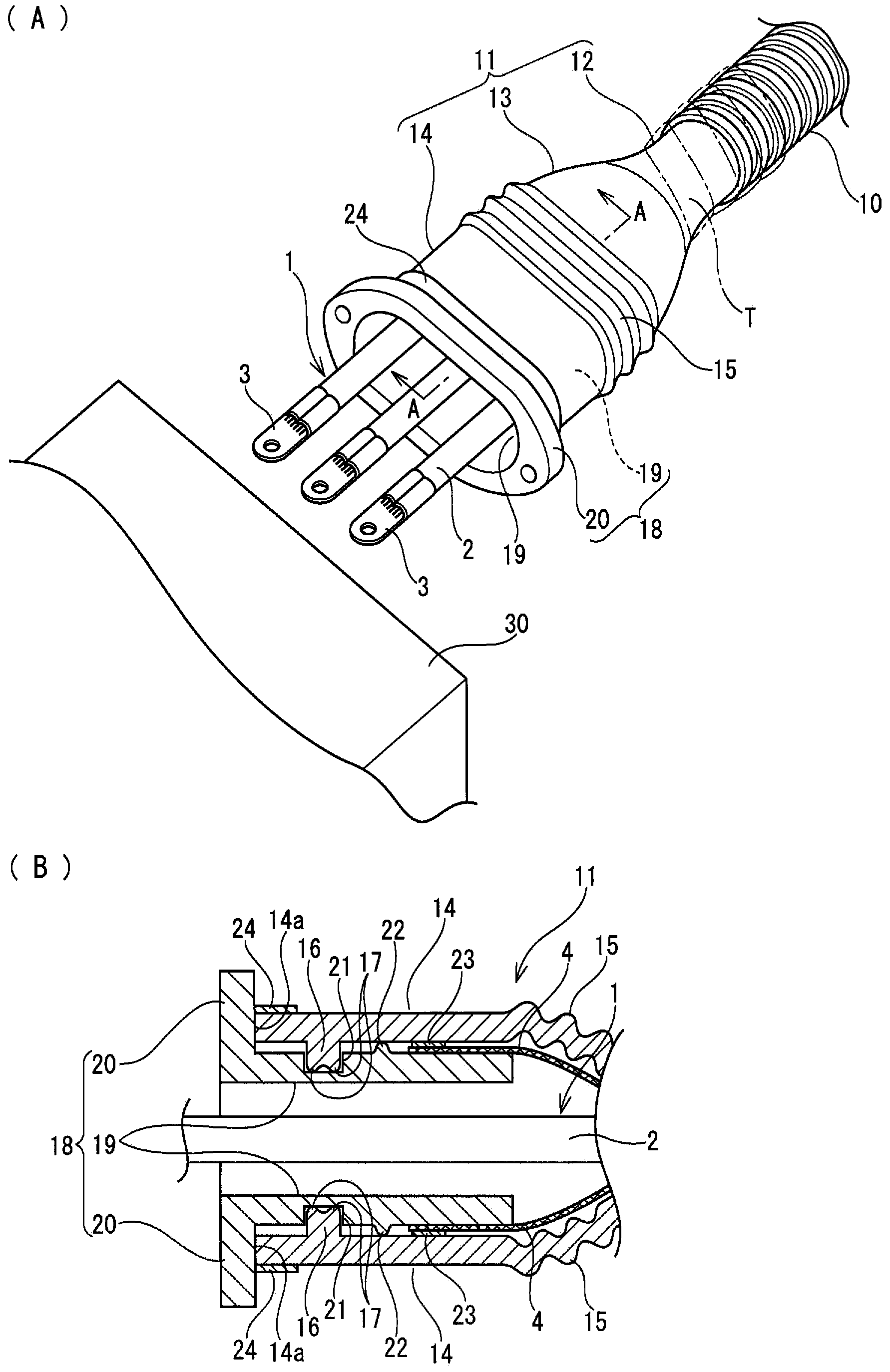

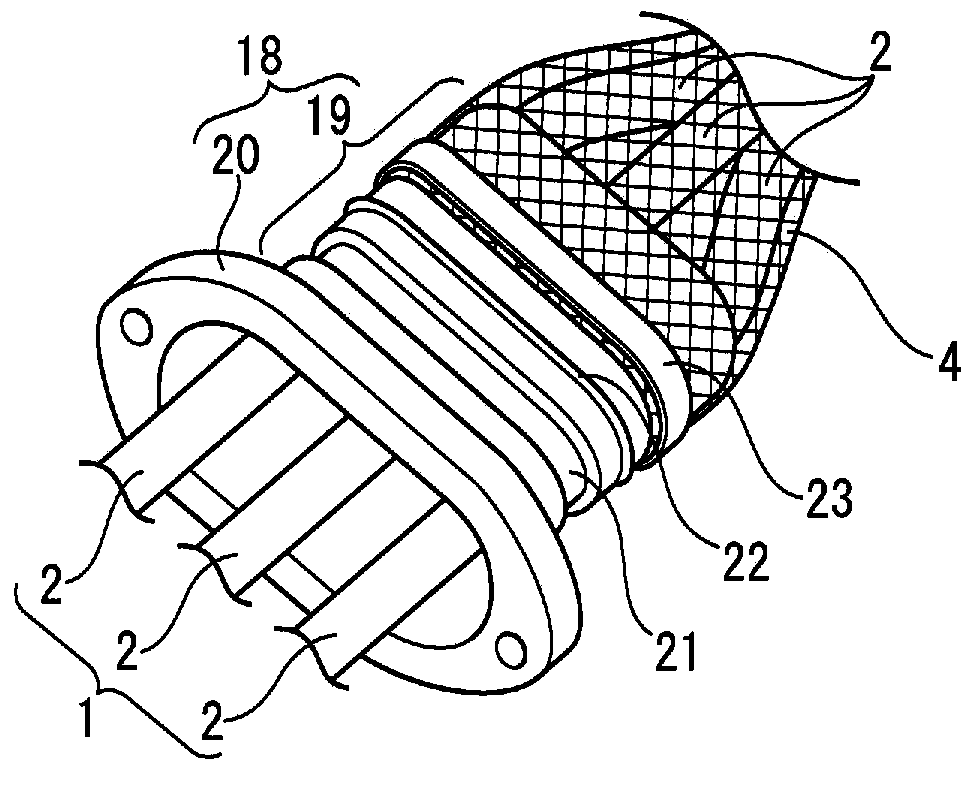

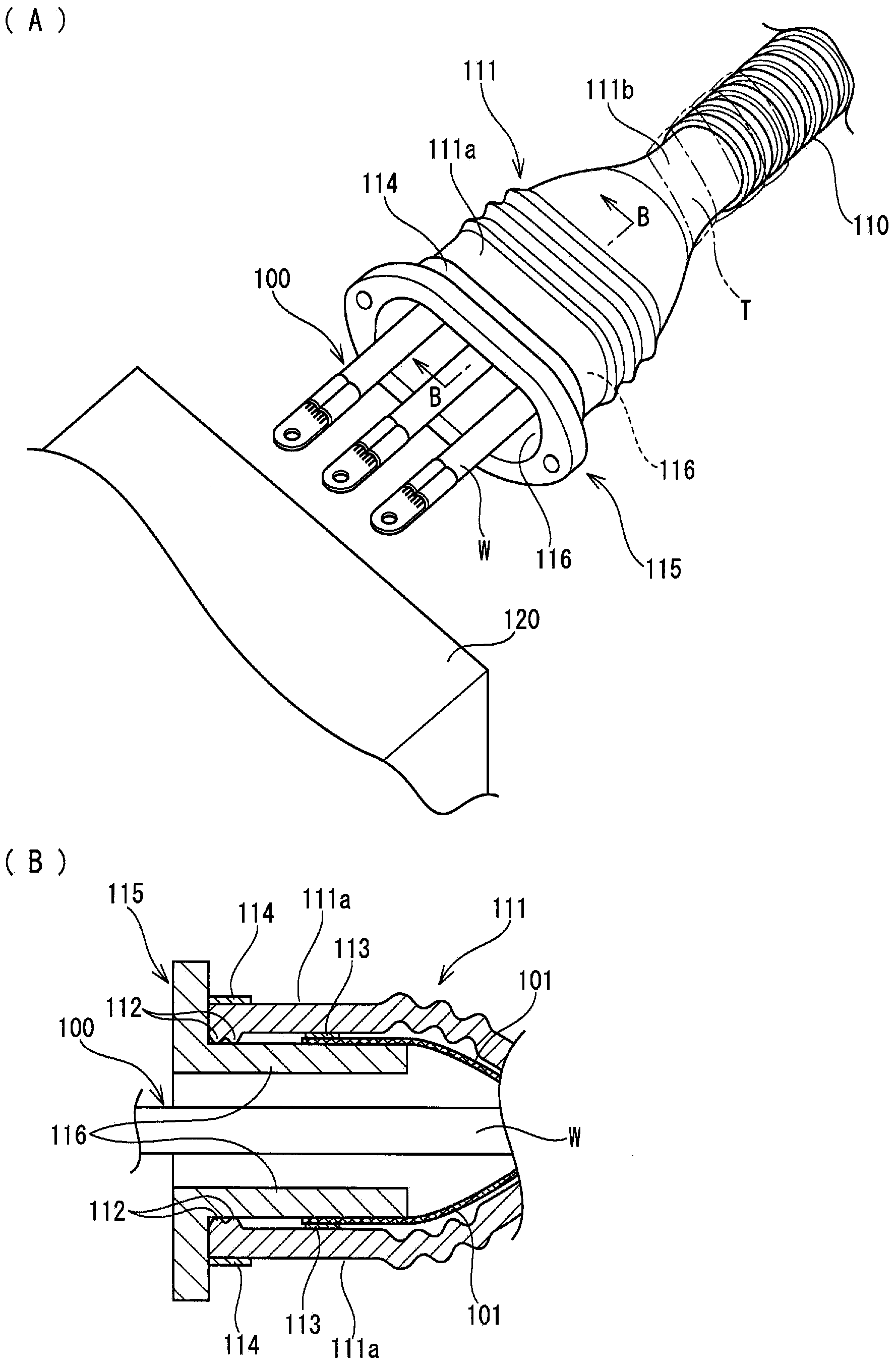

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0028] figure 1 and figure 2 Embodiments of the present invention are shown.

[0029] In this embodiment, a wire harness 1 composed of three insulated covered electric wires 2 is routed between the inverter and the battery (not shown) of the hybrid vehicle, and is routed in the underfloor area of the vehicle body (not shown). , the wire harness 1 is inserted into a metal pipe (not shown) made of aluminum-based metal.

[0030] In the area at both ends where the wire harness 1 is pulled from the underfloor wiring area into the engine room at the front of the vehicle and the compartment at the rear of the vehicle (not shown) to connect to the inverter or the battery, which is the device 30 on the other side, first After the wire harness 1 drawn from the end opening of the metal pipe is inserted through the corrugated tube 10 connected to the end of the metal pipe, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com