Safety helmet

A technology for safety helmets and installation parts, which is applied in the field of safety helmets, which can solve the problems of recording production and operation behaviors of people who cannot wear safety helmets, and achieve the effect of avoiding safety accidents and preventing injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

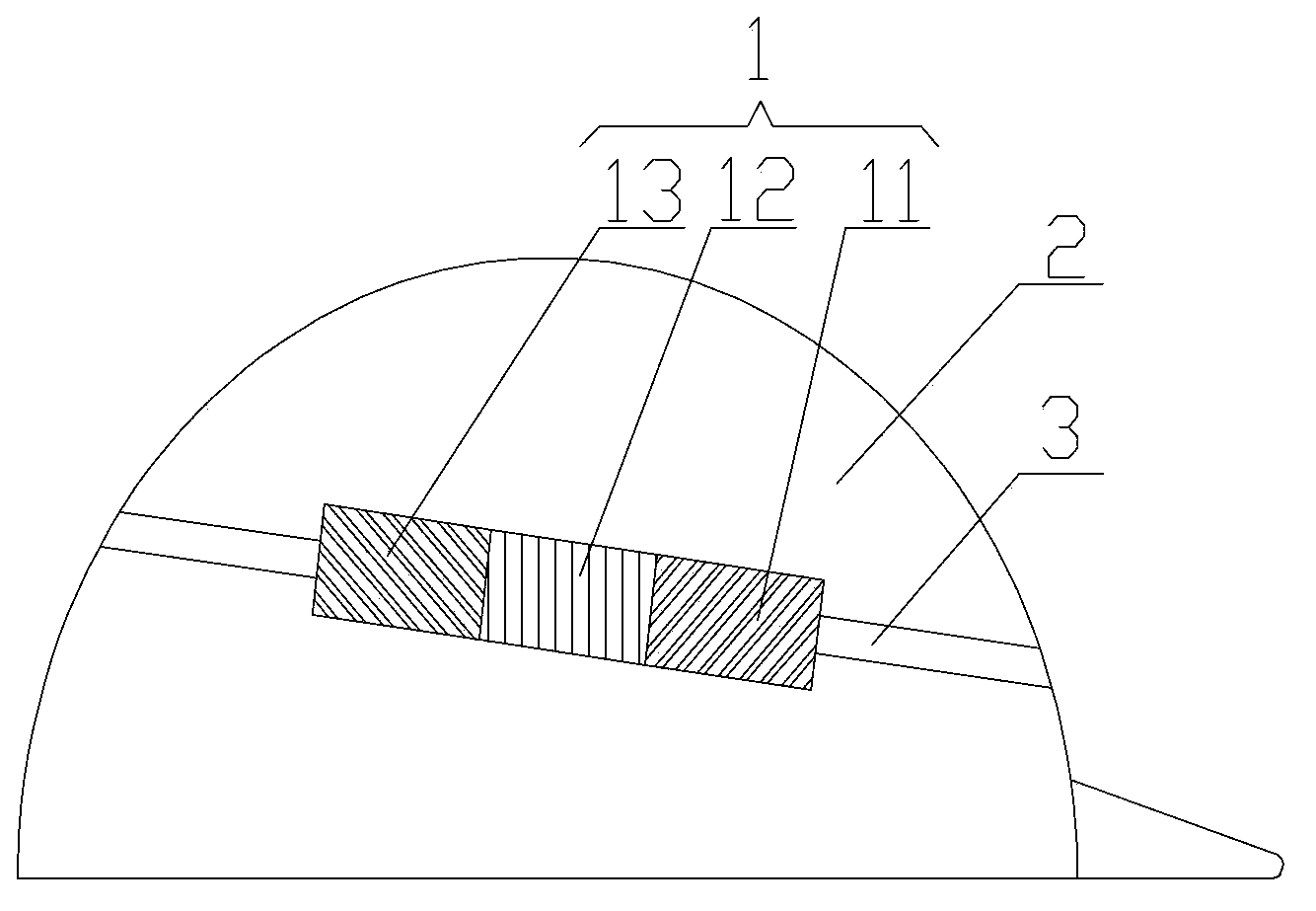

[0023] The invention provides a safety helmet, such as figure 1 As shown, the helmet includes a helmet body 2 and an electronic recording device 1 , and the electronic recording device 1 is installed on the helmet body 2 .

[0024] The helmet body 2 can protect the wearer's head from impact objects, and the electronic recording device 1 can record the wearer's operation behavior. Moreover, since the electronic recording device 1 is installed on the helmet body, the electronic recording device can realize the real-time recording of the wearer's operation behavior, which is beneficial to find the safety loopholes in the production by analyzing the operation records, and avoid the occurrence of safety accidents .

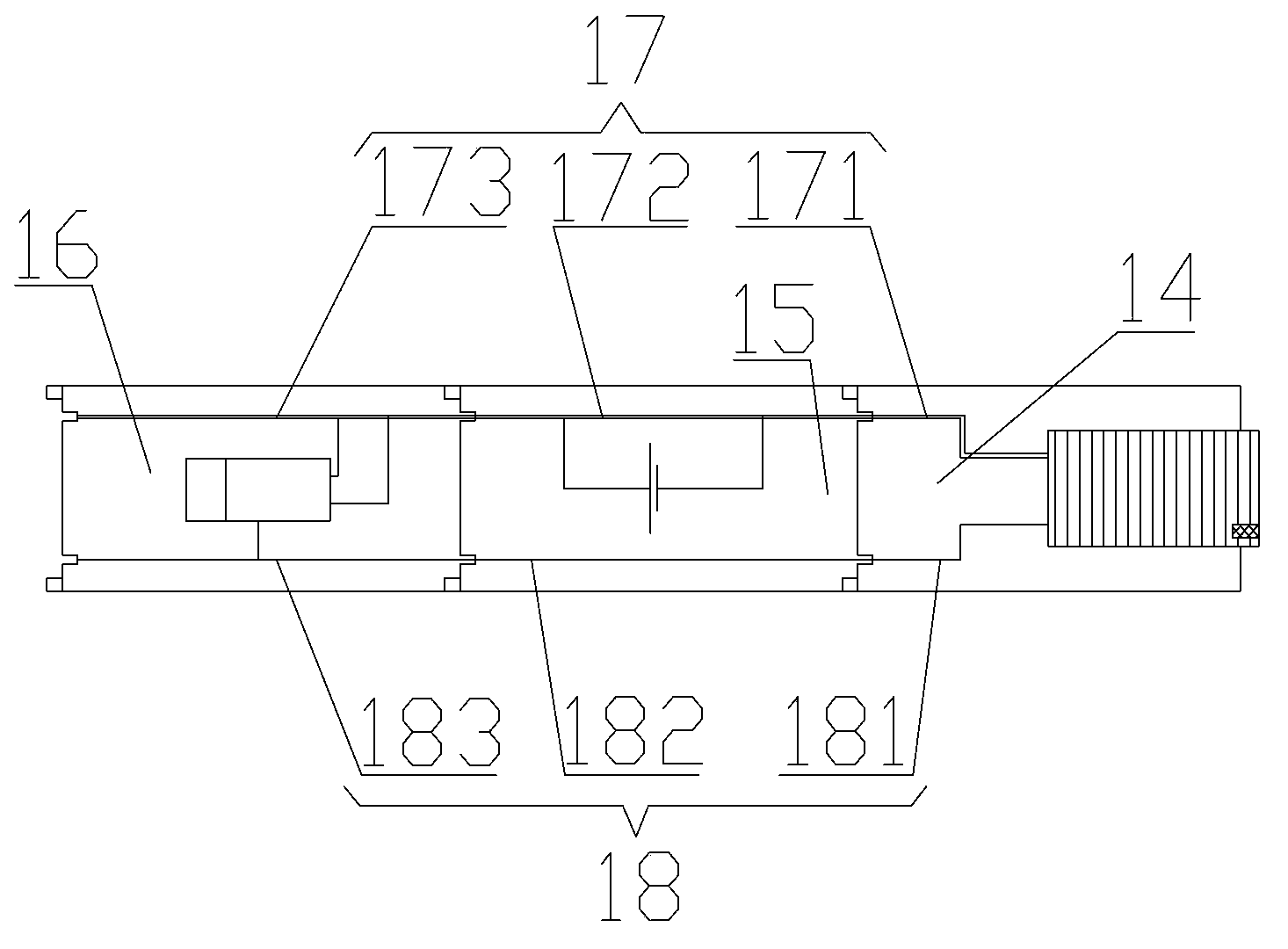

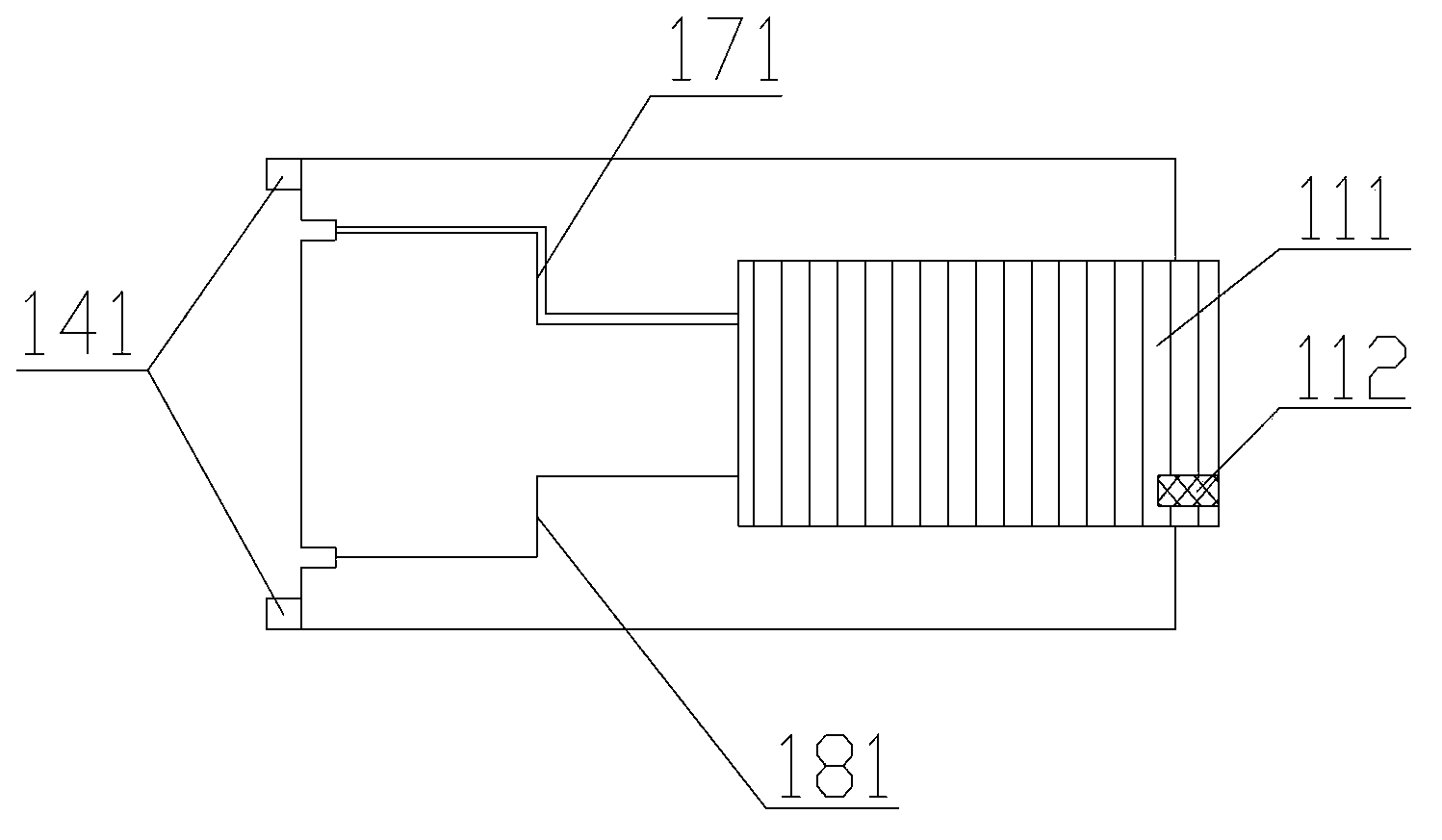

[0025] Preferably, the helmet furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com