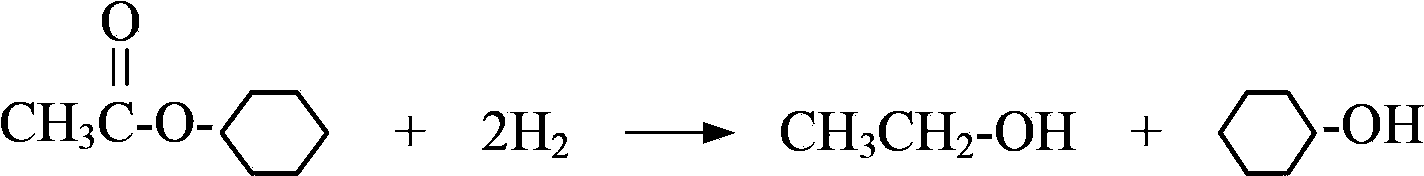

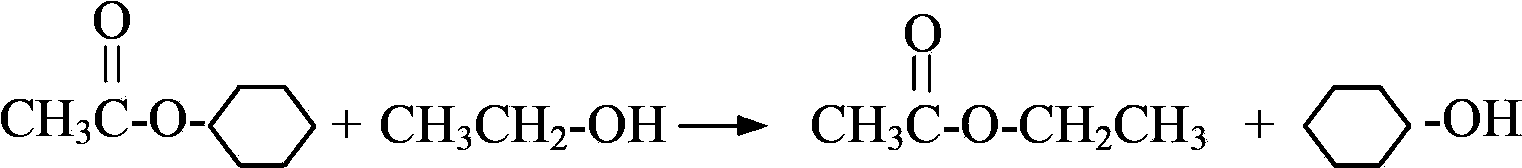

Carboxylic ester hydrogenation catalyst and method for preparing cyclohexanol and ethanol

A technology of hydrogenation catalyst and carboxylate, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., and can solve problems such as no information disclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a kind of preparation method of carboxylic acid ester hydrogenation catalyst, comprising:

[0039] (1) Composite metal oxides are prepared by co-precipitation; the composite metal oxides include (a) copper oxide, (b) zinc oxide, (c) oxidation of one or more metals selected from the following groups substances, aluminum, gallium, tin, titanium, zirconium, chromium, molybdenum, tungsten, manganese, rhenium, lanthanide metals and actinide metals; in the composite metal oxide, component (a) 5-60 parts, component (b) 10-50 parts, component (c) 5-60 parts;

[0040] (2) impregnating the composite metal oxide obtained in step (1) with an aqueous alkali metal hydroxide and / or alkaline earth metal hydroxide solution with a mass fraction of 0.5-5%, and then filtering, drying, and roasting to obtain the product.

[0041] Preferably, component (c) is an oxide of one or more metals selected from the following group: aluminum, gallium, tin, titaniu...

Embodiment 1~6

[0065] Embodiment 1~6 (preparation of catalyst)

[0066] The catalysts of Examples 1 to 6 were prepared according to the following procedure: weigh a certain amount of soluble metal salt according to the formula in Table 1, place it in a 2000mL three-neck flask, add water to dissolve and prepare about 1000mL solution, and install a stirrer and a pH meter on the flask and a thermometer, and place the flask in a temperature-adjustable constant temperature water bath, start stirring, adjust the temperature of the constant temperature water bath, gradually drop a certain concentration of precipitant solution into the flask, control the drop rate of the precipitant aqueous solution, and increase the temperature of the solution. The high temperature is controlled within 1°C. As the pH of the solution increases, precipitation occurs in the solution, and gradually increases as the pH increases. When the pH of the solution reaches the specified value, the dropwise addition of the preci...

Embodiment 7~15

[0067] Examples 7-15 (catalyst evaluation in autoclave)

[0068] Embodiment 7~15 is the cyclohexyl acetate hydrogenation test of the catalyst that carries out example 1~6 in autoclave, test procedure is as follows: get a certain amount of catalyst powder and be placed in 500mL autoclave, add 250g cyclohexyl acetate Hexyl ester, the reaction kettle was closed, replaced with nitrogen three times, hydrogen gas was introduced to a certain pressure, and the temperature was gradually raised. At about 80°C, the pressure in the kettle began to drop, indicating that the catalyst in the kettle began to reduce, and the ester hydrogenation reaction began. Timely Supplement hydrogen to maintain a certain pressure in the reactor, and finally raise the temperature to a given temperature, and maintain the pressure at this temperature for a certain period of time, then stop the reaction, cool down to room temperature, and unload the reaction product and catalyst. Analyze the product compositio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap