Pneumatic type vibrating screen

A vibrating screen, pneumatic technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of low vibration frequency and low efficiency of vibrating screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

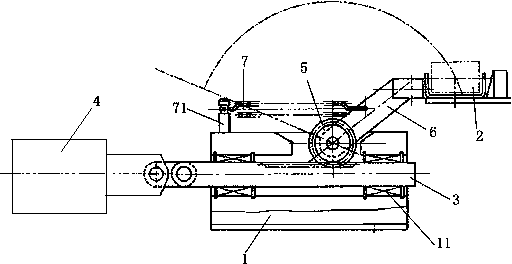

[0010] like figure 1 As shown, the pneumatic vibrating screen of the present invention includes a vertically arranged support 1 and a screen body 2, the side of the support 1 is slidably connected to a rack 3 through a guide bearing 11, one end of the rack 3 and the cylinder 4 The piston rod is fixedly connected; the support 1 is slidingly provided with a gear 5 meshing with the rack 3, and the gear 5 is connected to the screen body 2 through a connecting rod 6; the middle section of the connecting rod 6 is connected with a return spring 7. The return spring 7 is fixed on the top surface of the support 1 through the spring seat 71 .

[0011] When in use, because the cylinder 4 is used as the power source for the vibration of the sieve body 2, the traditional structure of the eccentric wheel driven by the motor is changed, and the optimized structure has the advantages of simple structure and low manufacturing cost. In addition, the expansion and contraction range of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com