Pipe hoop stamping die

A technology of stamping dies and punches, which is applied in the field of molds, can solve problems such as low processing efficiency and lower pass rate, and achieve the effects of improving pass rate, avoiding defective products, and simple processing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

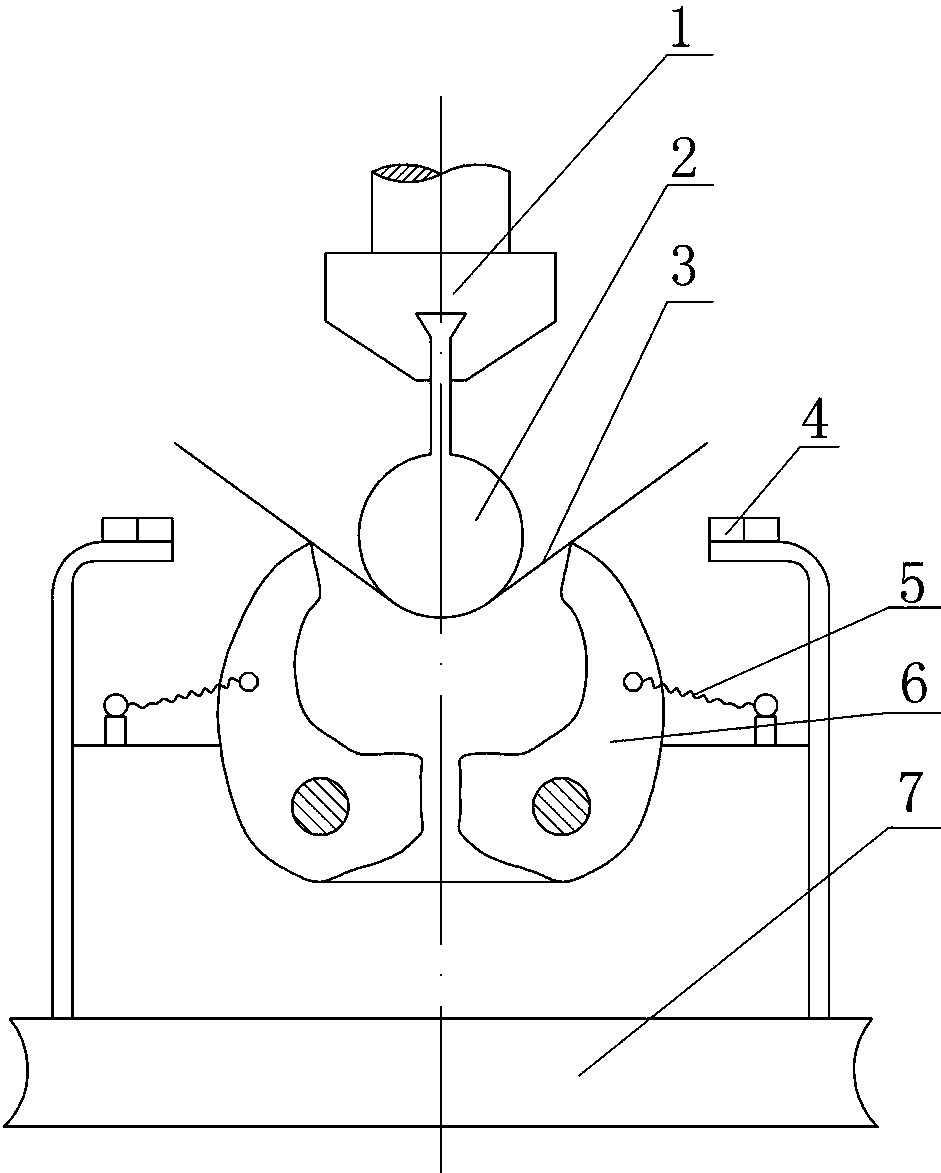

[0009] Such as figure 1 As shown, in the stamping of "Ω"-shaped pipe collar, during the stamping process, the blank 3 is placed in the positioning block 4, and the cylindrical punch 2 on the punch is sleeved on the die handle 1 and punches downward. 6 is hinged on the lower mold base 7, and the cylindrical punch 2 bears against one end of the swinging die 6 so that the swinging die 6 swings to the middle to extrude the blank 3 to form around the cylindrical punch 2; when the cylindrical punch 2 rises , the swinging die 6 returns to the initial position under the action of the elastic restoring force of the spring 5, and removes the formed "Ω"-shaped pipe collar from the cylindrical male die 2.

[0010] What is described above is only the preferred embodiment of the present invention, it should be pointed out that for those skilled in the art, under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com