Car body longitudinal beam local reinforcement structure

A technology for local reinforcement and car body, applied in the field of auto parts, which can solve the problems of integration of reinforcement schemes and vehicle fatigue damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

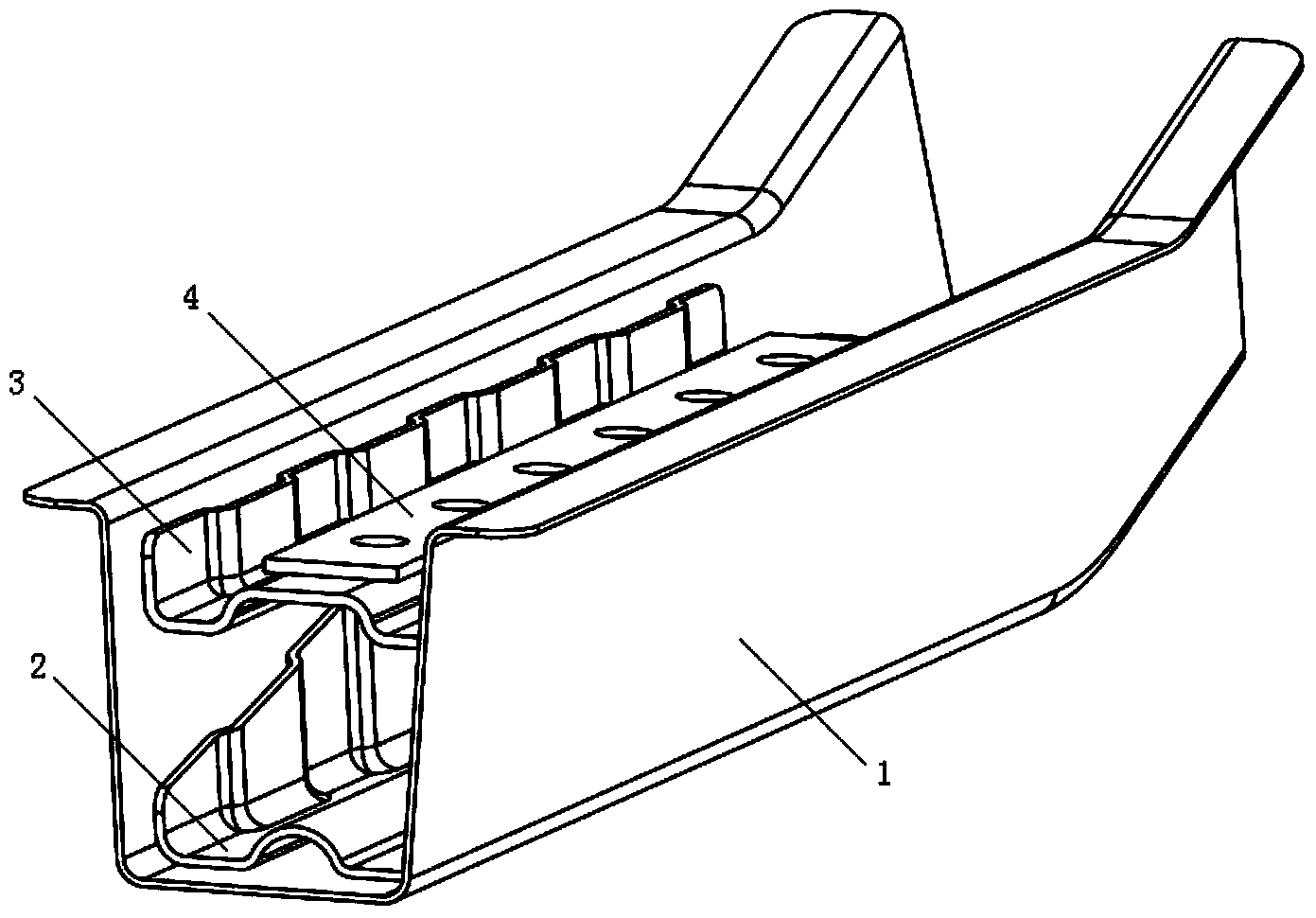

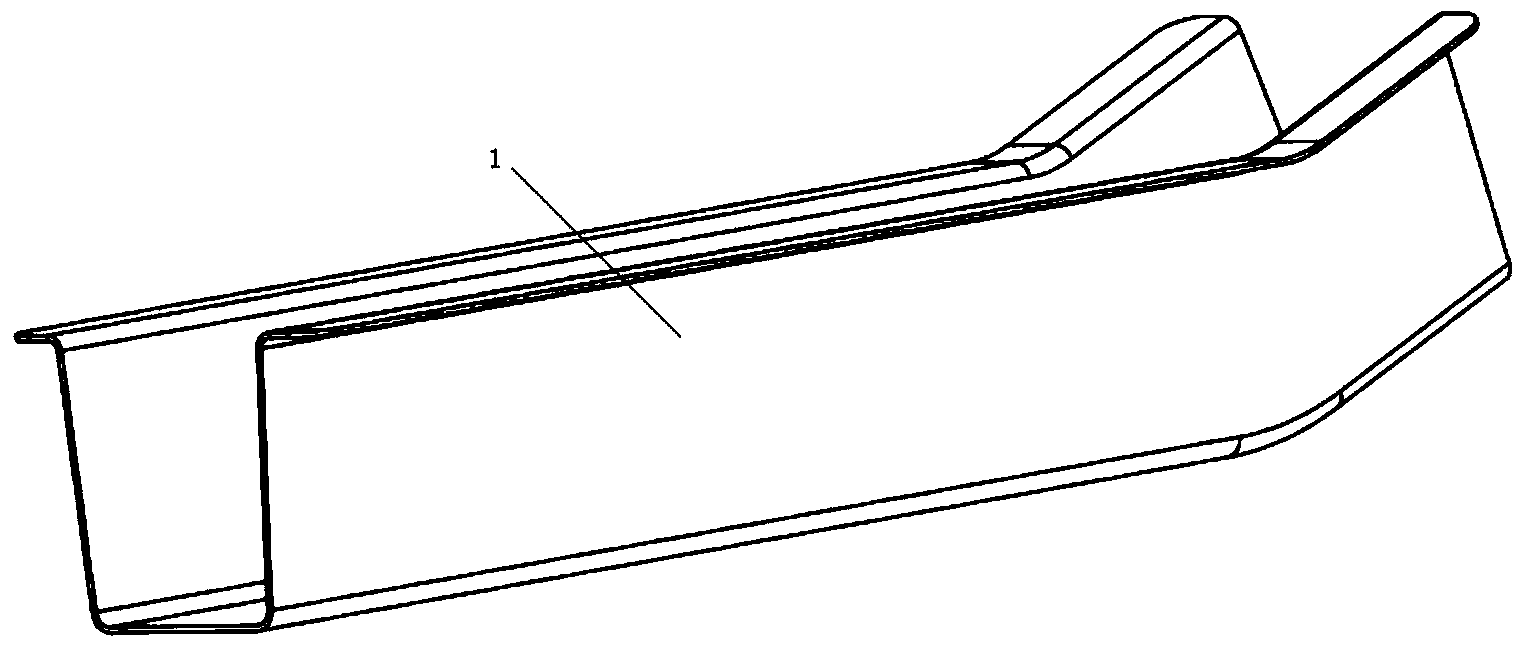

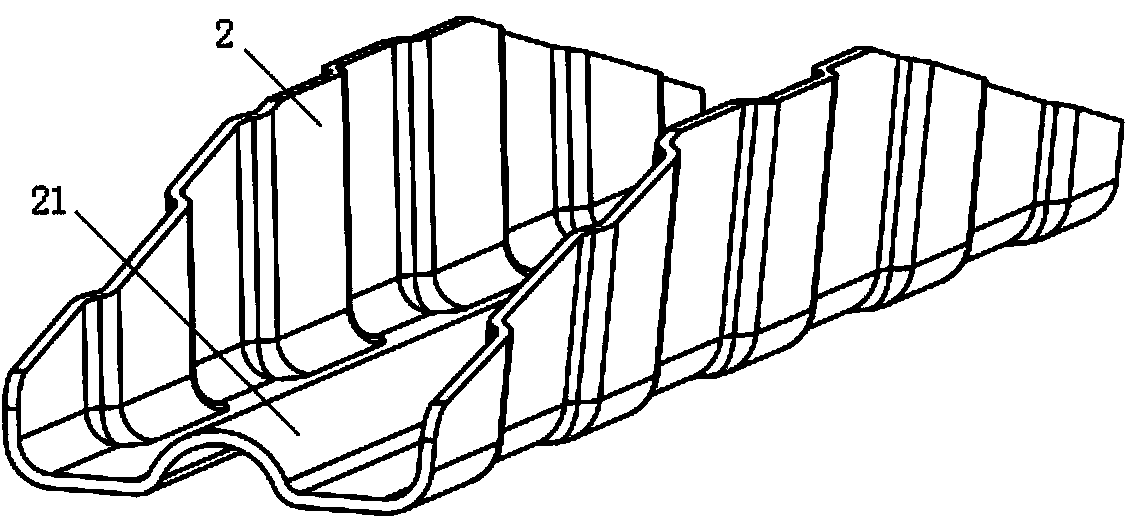

[0024] Such as Figure 1-9 as shown, figure 1 is a structural schematic diagram of the present invention; figure 2 is the schematic diagram of the structure of the longitudinal beam of the vehicle body; image 3 is the structural diagram of the lower liner; Figure 4 is the structural schematic diagram of the upper liner; Figure 5 is the schematic diagram of the structure of the reinforced plate; Figure 6 It is a structural schematic diagram of the cross section of the present invention; Figure 7 is the top view of the lower liner; Figure 8 is the cross-sectional view of the lower liner; Figure 9 is a cross-sectional view of the top liner.

[0025] A car body side beam local reinforcement structure, including a U-shaped body side beam 1, a car body side beam local reinforcement structure, including a lower liner 2, an upper liner 3, two lengths of the lower liner 2 The sides are respectively welded on both sides of the bottom of the U-shaped groove of the longitu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap