Combination bracket

A technology of combining brackets and fixing holes, which is applied to instrument panels, superstructures, subassemblies of superstructures, etc., and can solve problems such as waste of materials, expensive finished products, and high bracket costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

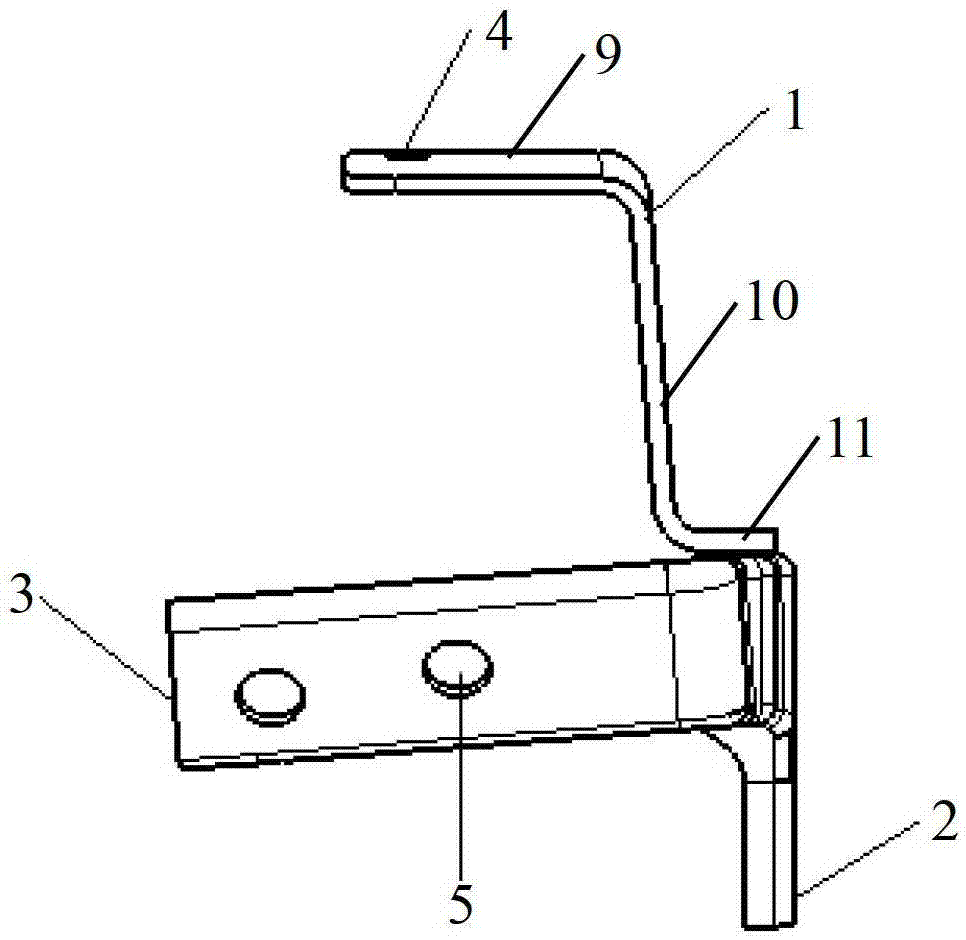

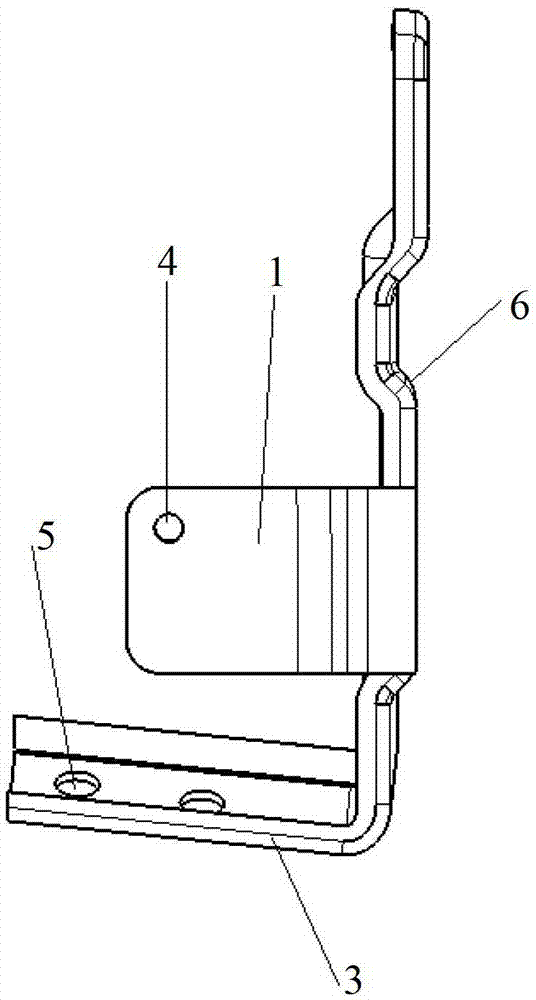

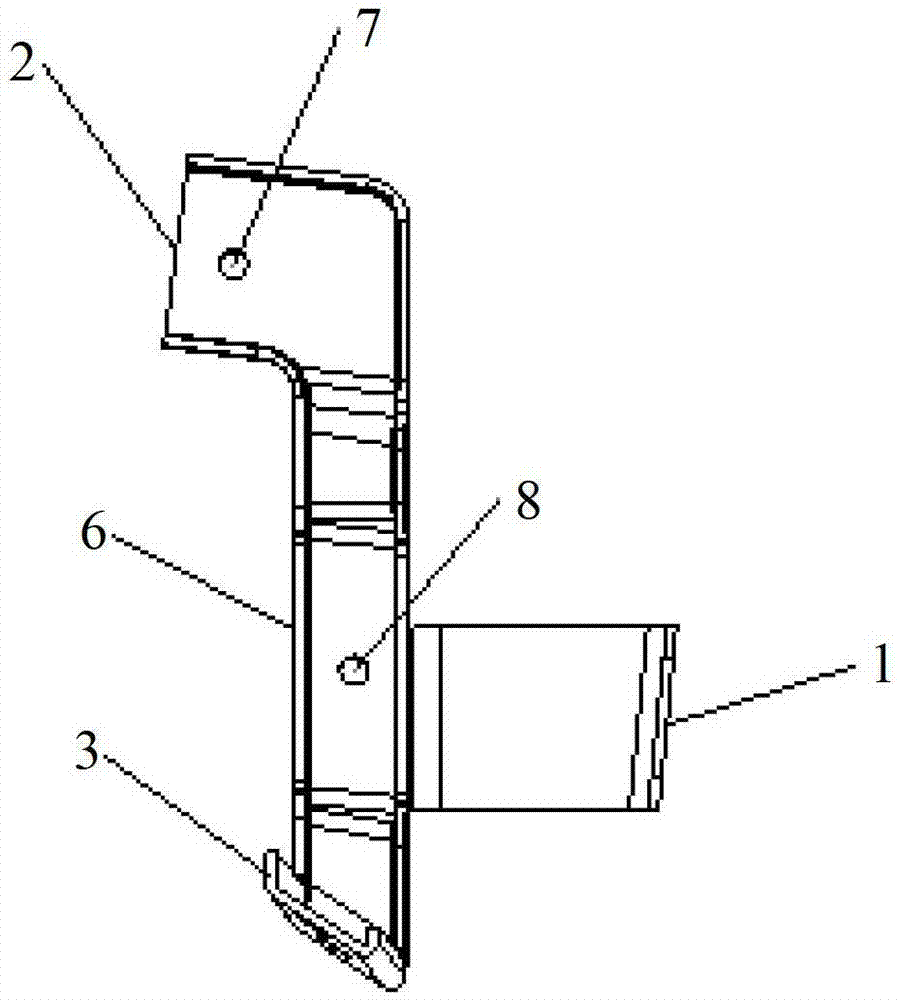

[0021] Figure 1 to Figure 3 The structural schematic diagrams of different sides of the combined bracket of this embodiment are shown respectively, figure 2 yes figure 1 The schematic diagram of the combined bracket after being rotated 90 degrees in the plane perpendicular to the paper, image 3 yes figure 2 Schematic diagram of the combination bracket rotated 90 degrees in the plane of the paper. Referring to the figure, the combined bracket includes two parts, respectively the first bracket 1 and the second bracket, the first bracket 1 is used to fix the sub-dashboard, and the second bracket is installed on the cab floor, on which it is used to fix The sub-dashbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com