Patents

Literature

33results about How to "Save board" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

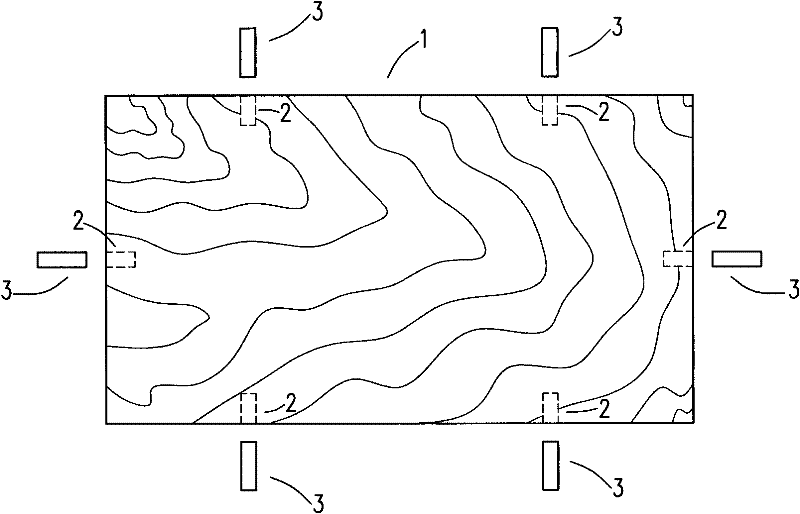

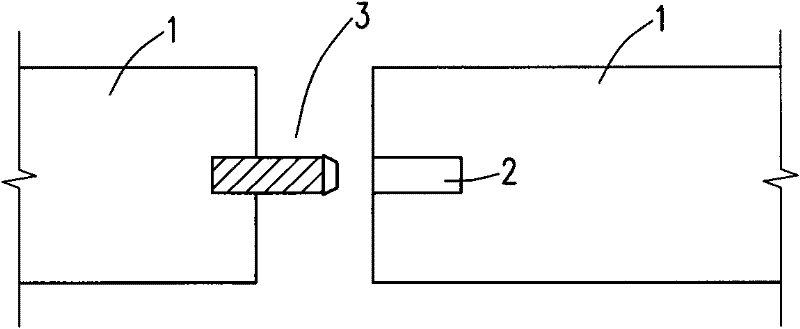

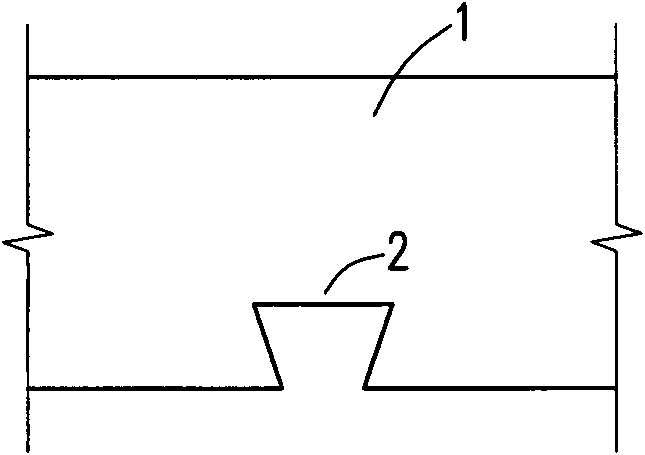

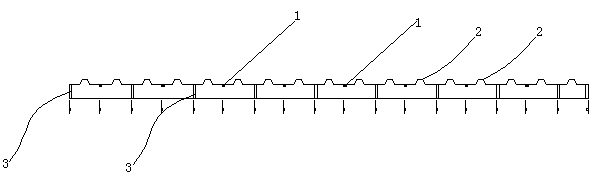

Connecting structure for solid wood floor

The invention relates to a connecting structure for a solid wood floor, which comprises a wood floor, and is characterized in that the end surfaces at the periphery of the wood floor are provided with rabbets, the connecting structure also comprises tenon columns matched with the rabbets. One improvement is that the rabbets are blind holes, the peripheral surfaces of the tenon columns are provided with fastening protruded veins. Another improvement is that the rabbets are dovetail grooves, and the tenon columns are dovetail tenon columns. The invention has the advantages that the structure is simple; the tenon structure does not needed to be integrally processed on the periphery, so the plates can be saved, and the cost is reduced; and no keel is adopted for fixing, so the installation is convenient, the installing cost is low, and the disassembly is convenient.

Owner:JIANGE GOLDSTAR BAMBOO WOOD PRODS

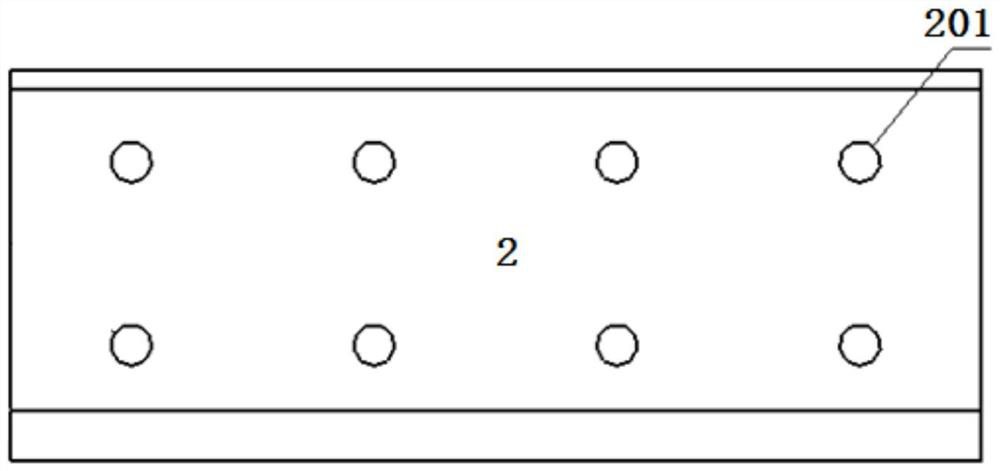

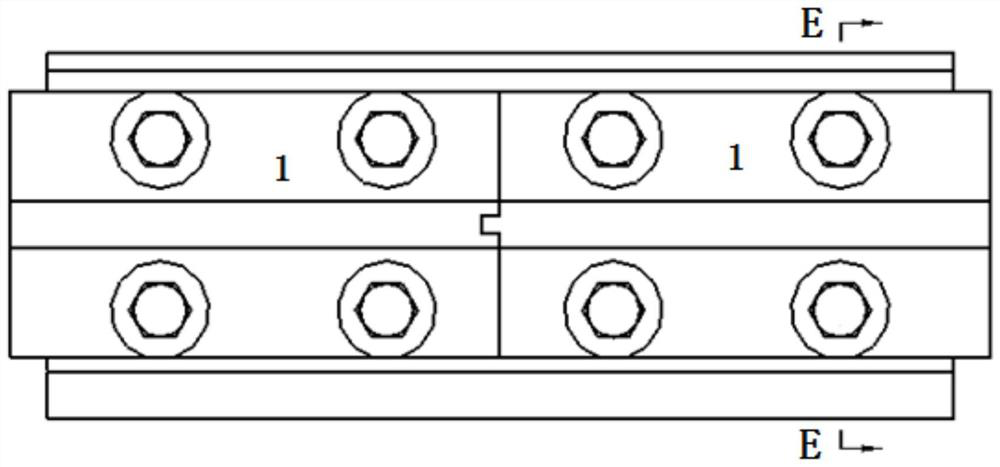

Convex point grid platform of plasma and flame numerical control cutting machine

InactiveCN102990189ACutting accuracy is not affectedStable structurePlasma welding apparatusGas flame welding apparatusNumerical controlEngineering

The invention discloses a convex point grid platform of a plasma and flame numerical control cutting machine. The convex point grid platform comprises square steel plates, longitudinal rib plates and convex point plates, wherein the square steel plates and the longitudinal rib plates are longitudinally arranged at intervals, the convex point plates are transversely arranged, and a double-layer grid structure is formed. According to the convex point grid platform disclosed by the invention, because the convex point grid platform difficultly deforms, the cutting accuracy is improved; and the convex point grid platform is safe to operate.

Owner:XIAMEN SHIPBUILDING IND

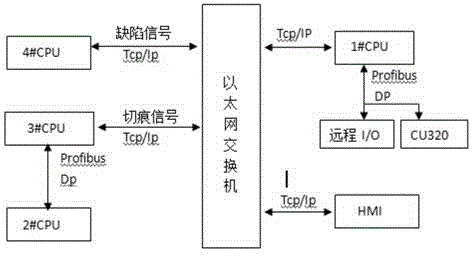

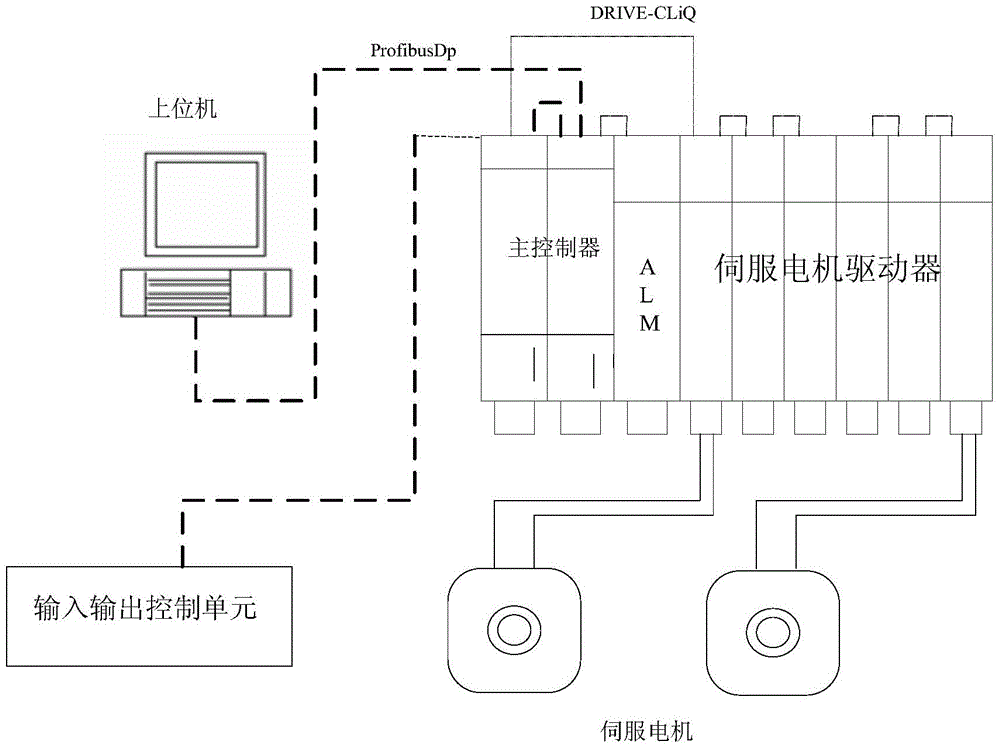

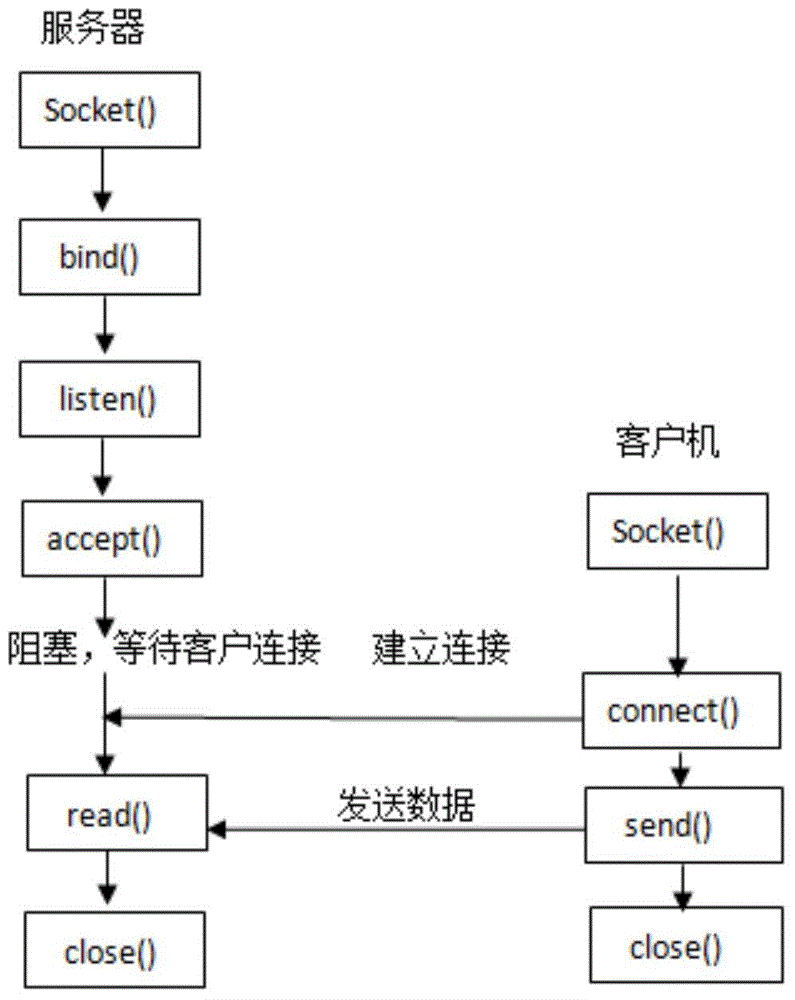

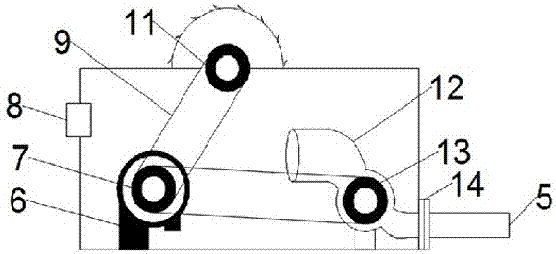

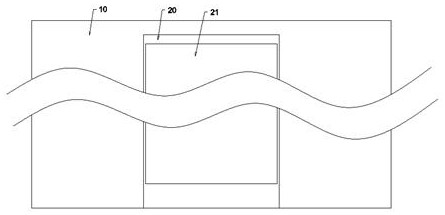

Novel control system of longitudinal cutting machine for glass production line

ActiveCN104140201APrecise positioningSave human effortGlass severing apparatusGlass productionProduction lineHuman–machine interface

The invention discloses a novel control system of a longitudinal cutting machine. The knife falling and refueling actions of the longitudinal cutting machine are controlled by a relay; a plurality of knives are mounted on the longitudinal cutting machine; the speeds and positions of the knives are controlled by a servo motor; the control system comprises a main controller, a man-machine interface, a servo motor driver and an input output control unit; an upper computer is connected to the input end of the main controller; the servo motor driver and the input output control unit are connected to the output end of the main controller; the input output control unit is used for controlling the relay through a remote I / O (input / output); and the main controller is also used for data communication with a transverse cutting machine, a defect monitoring machine and a broken slab detection machine in the form of a TCP / IP (transmission control protocol / internet protocol). By controlling the actions of the plurality of knives of the longitudinal cutting machine, the longitudinal cutting machine is accurately positioned; and meanwhile, the control system has the characteristics that the automatic longitudinal cutting machine is high in precision difference, the manpower is reduced and plate materials are saved due to a wireless communication function.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

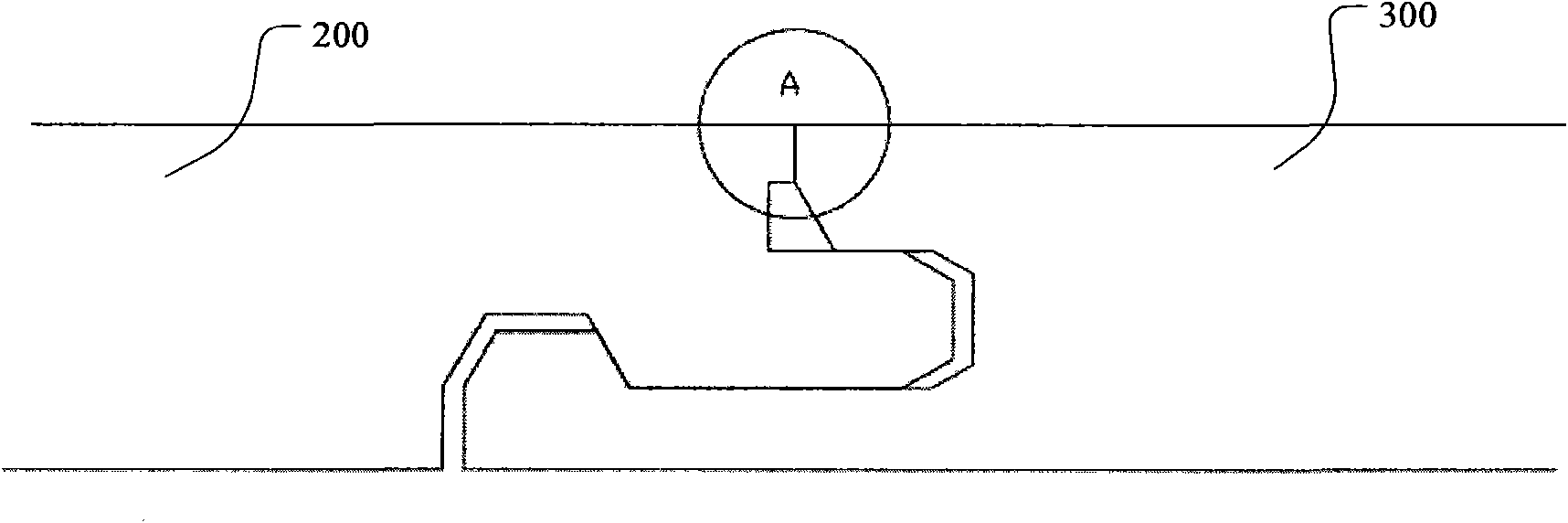

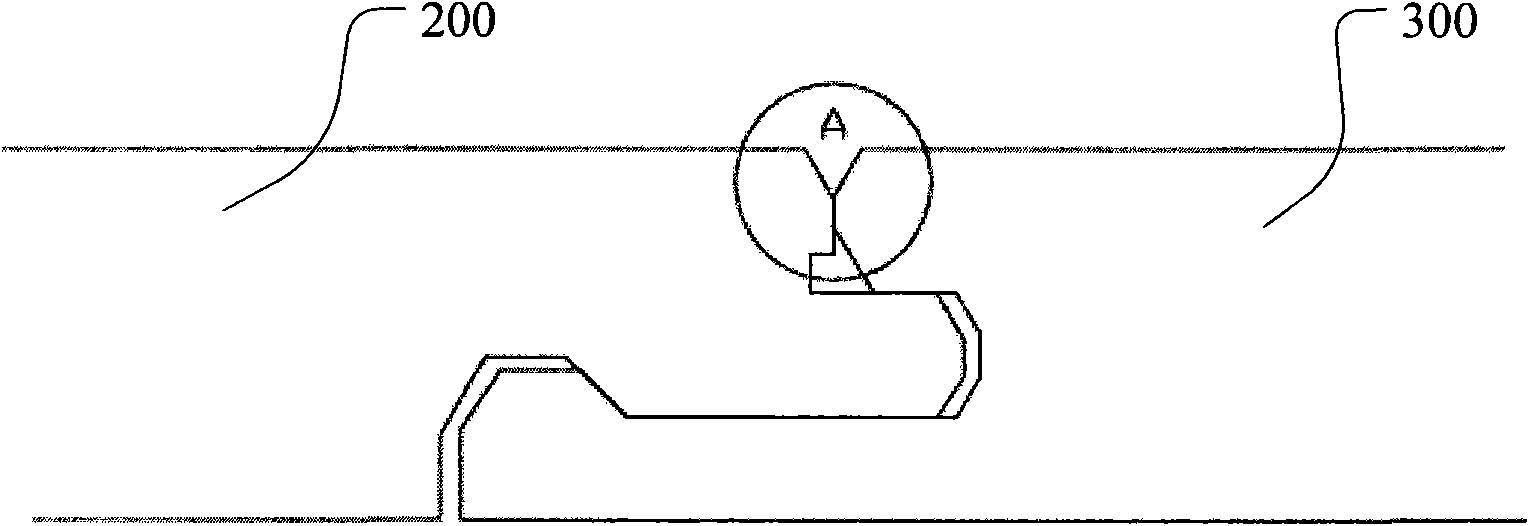

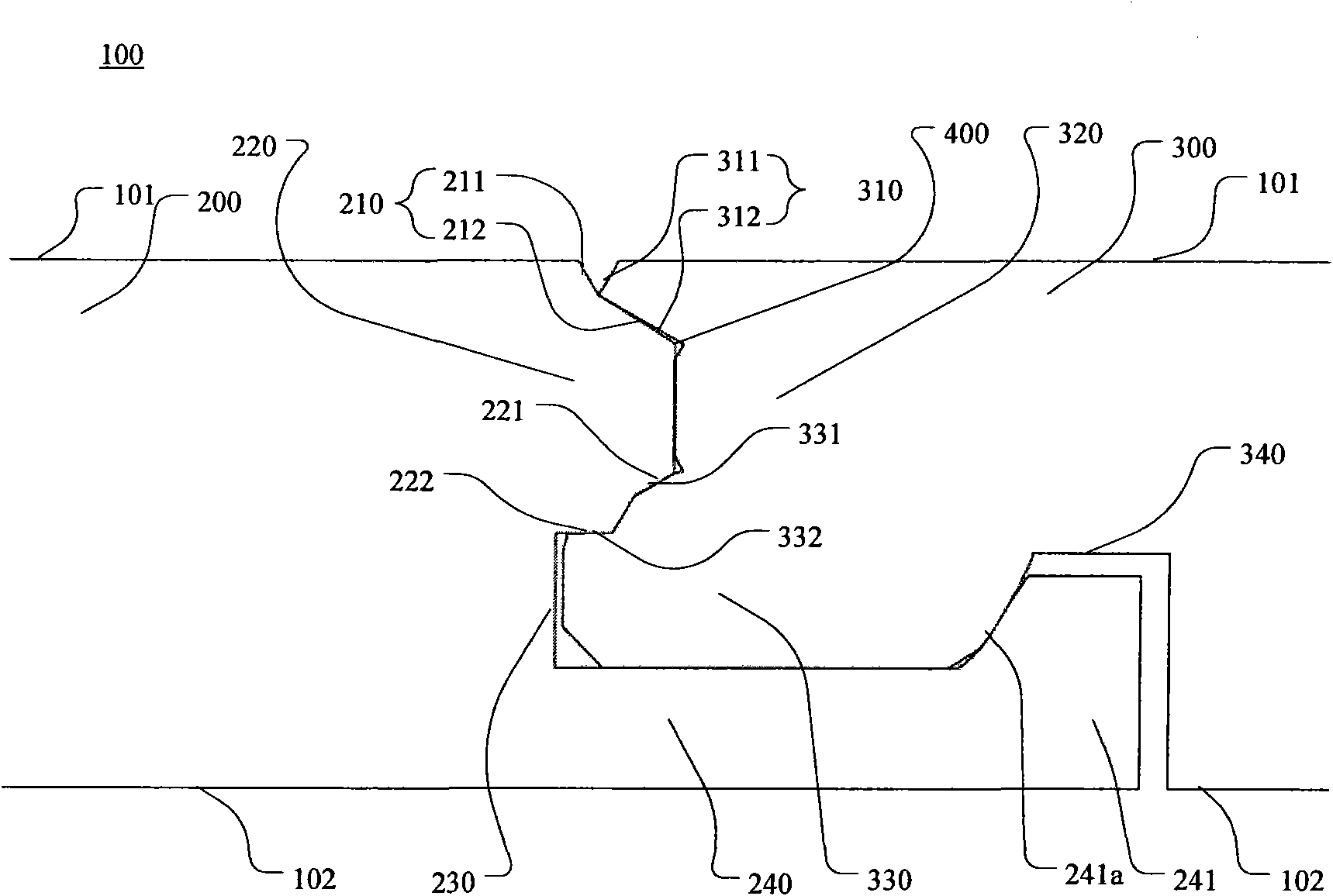

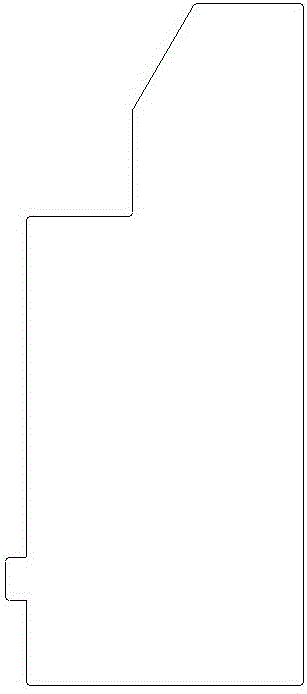

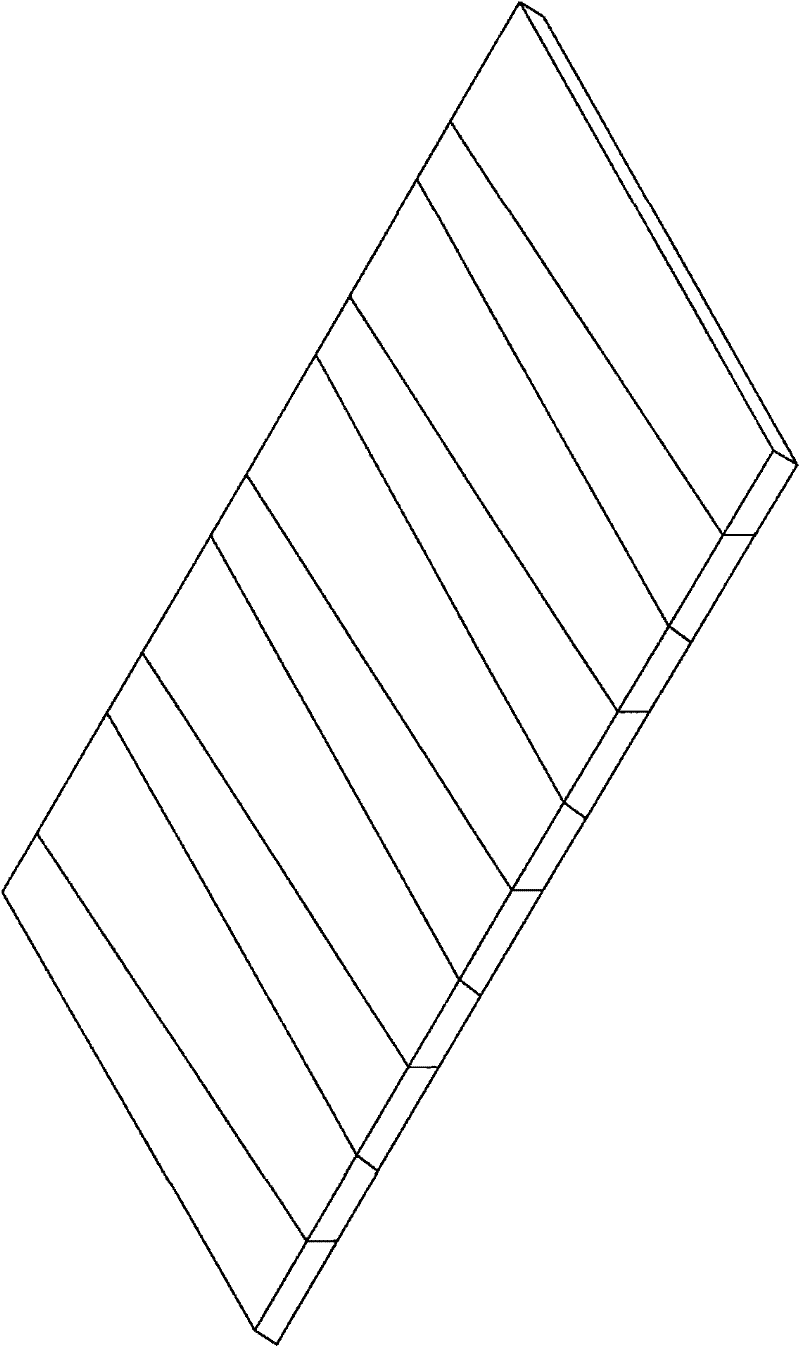

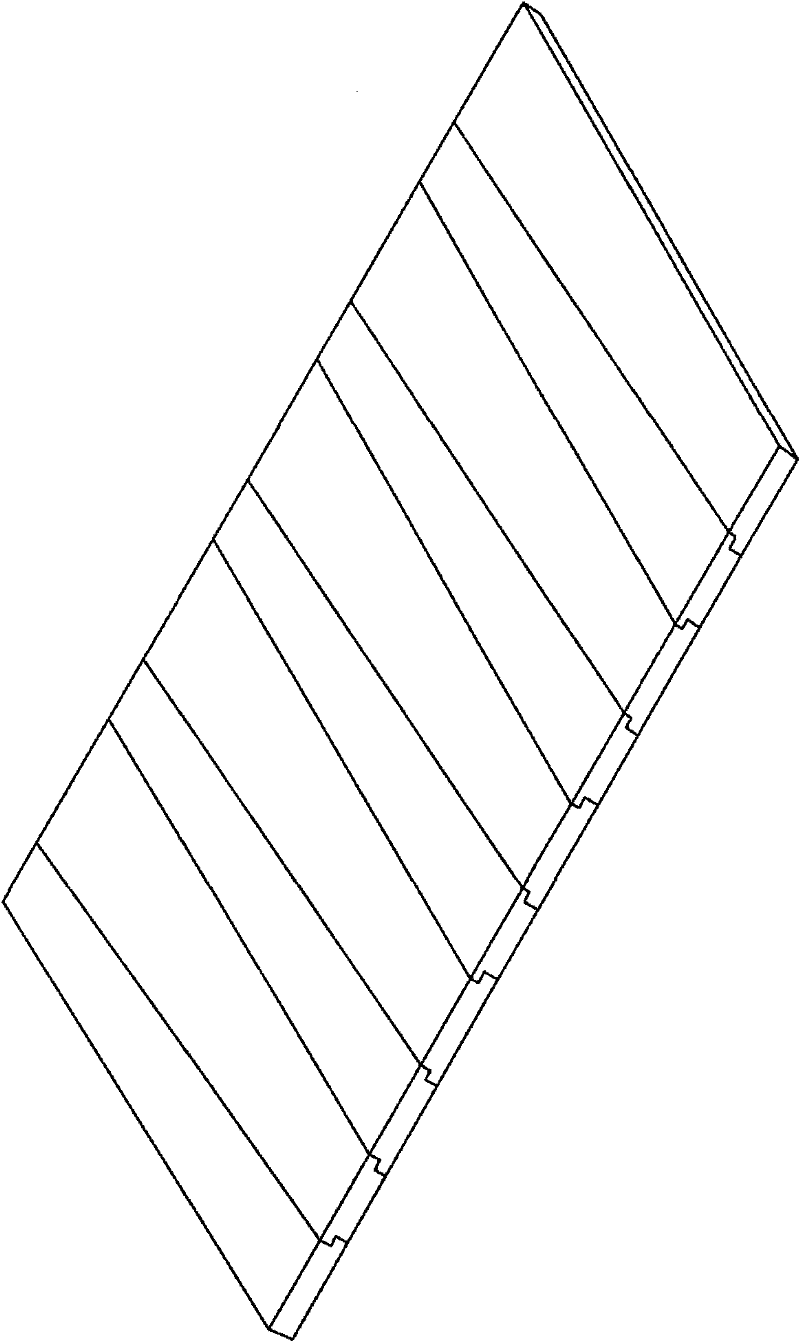

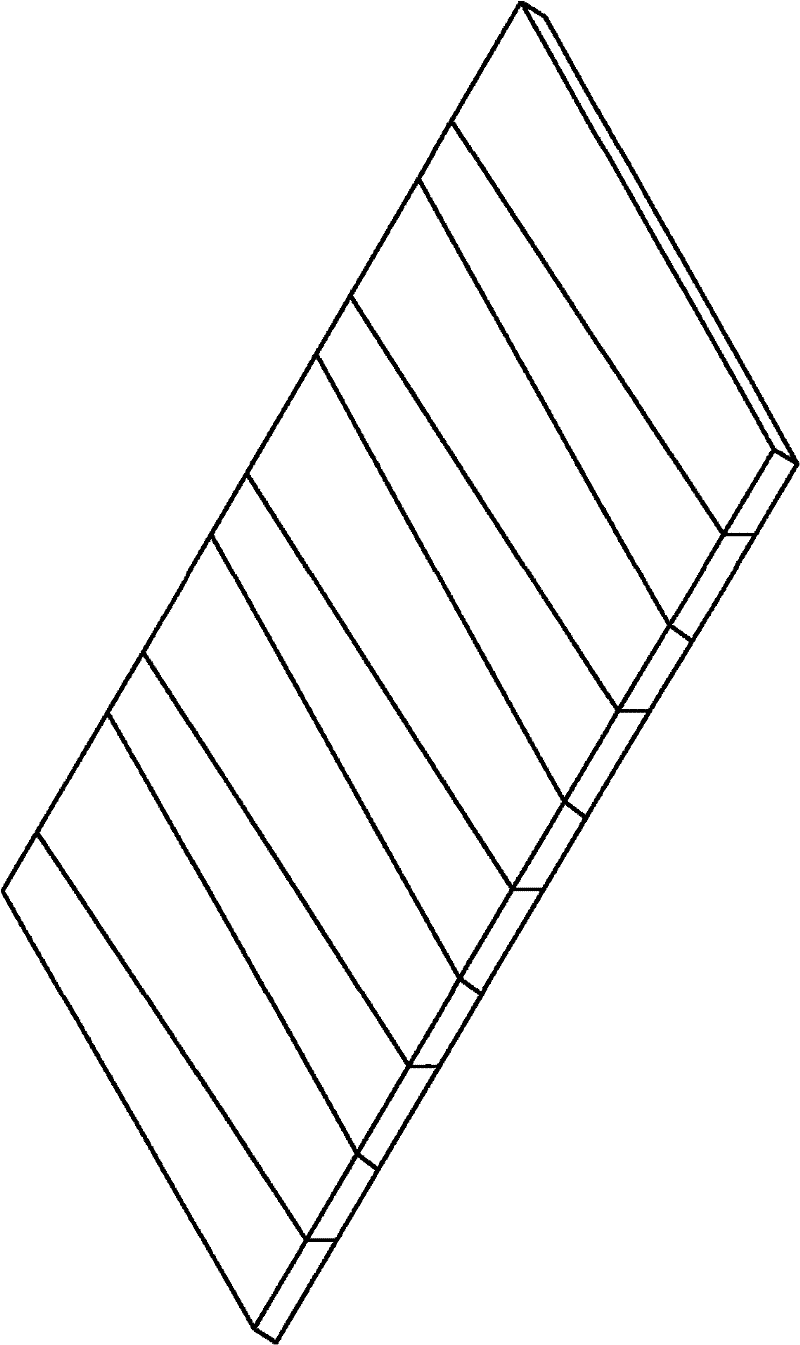

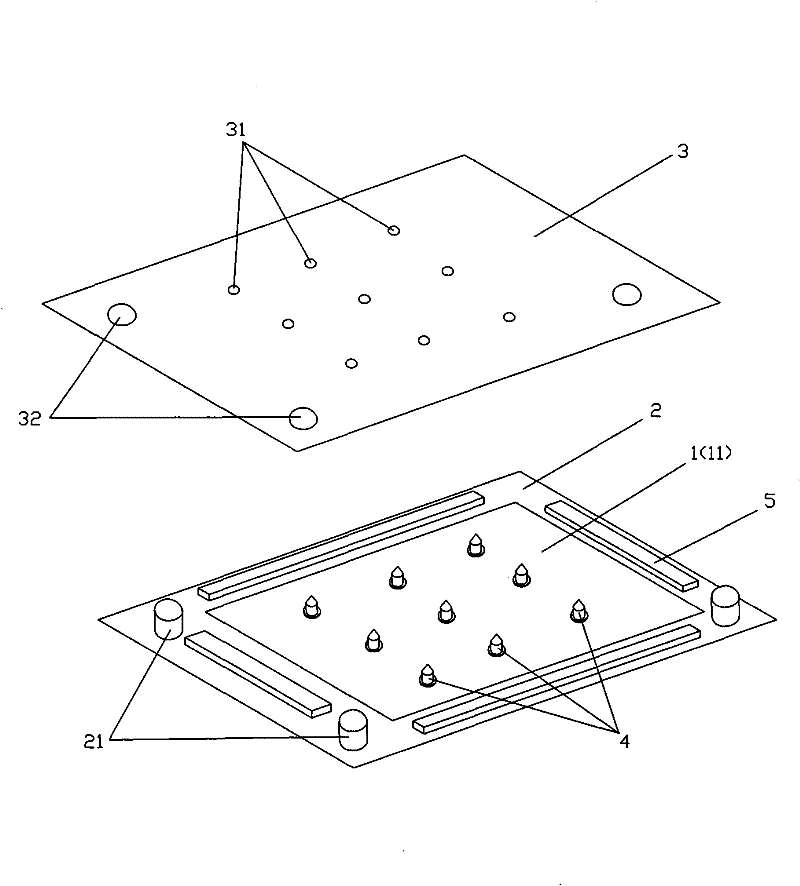

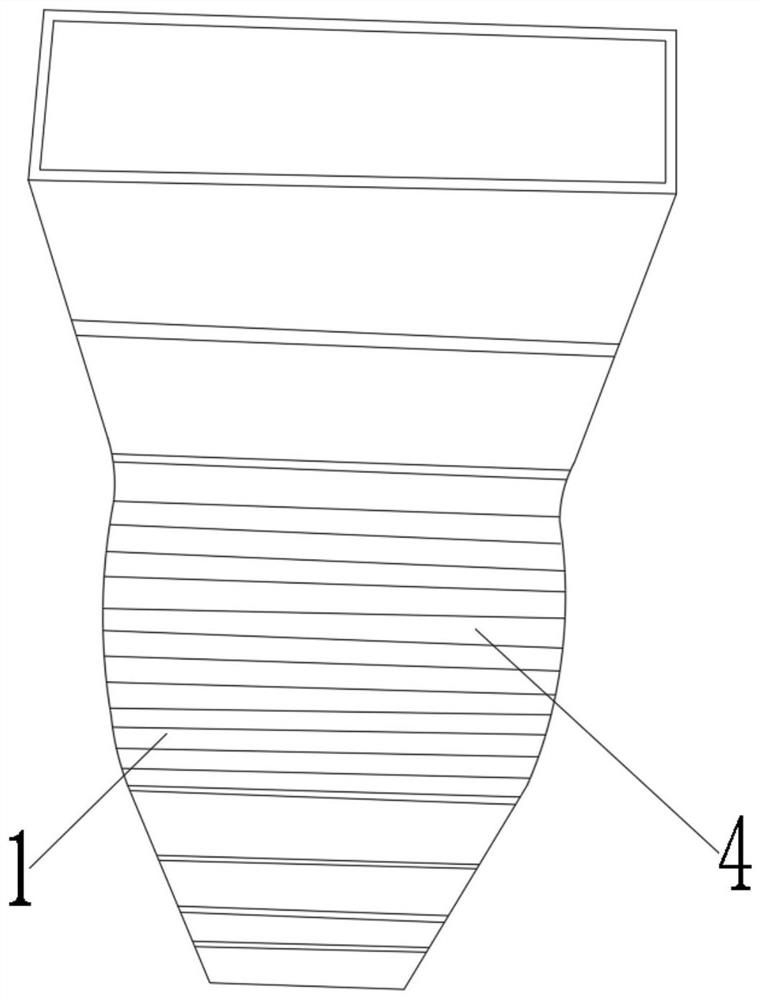

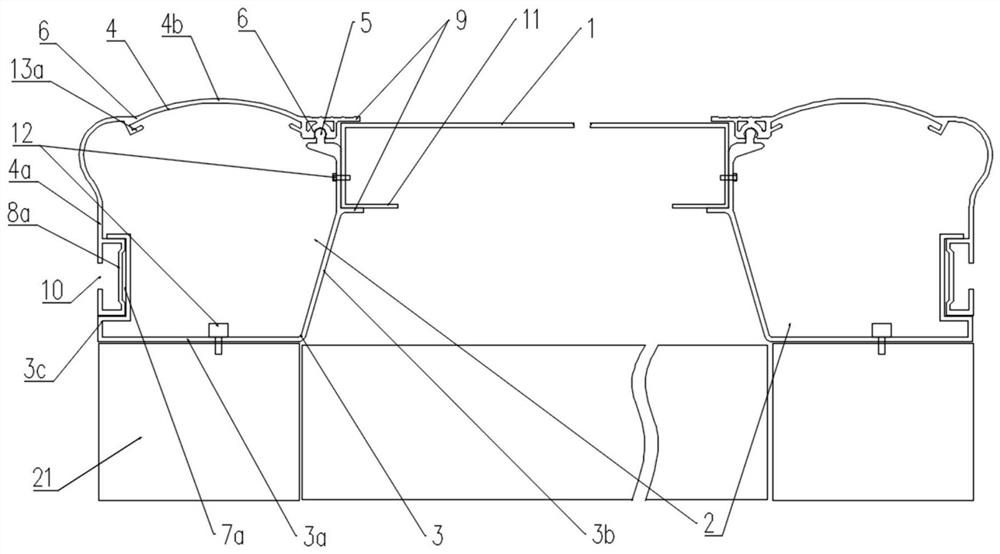

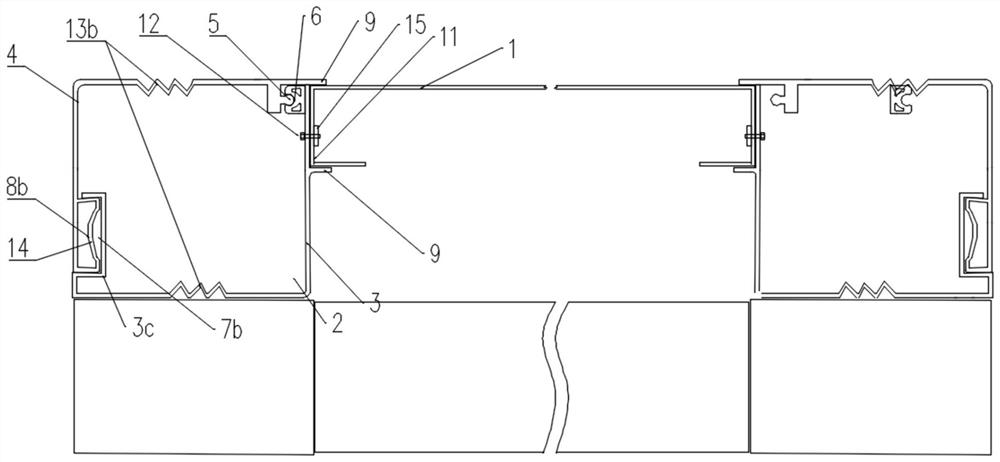

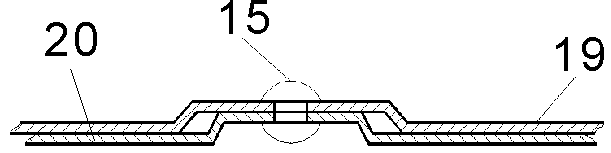

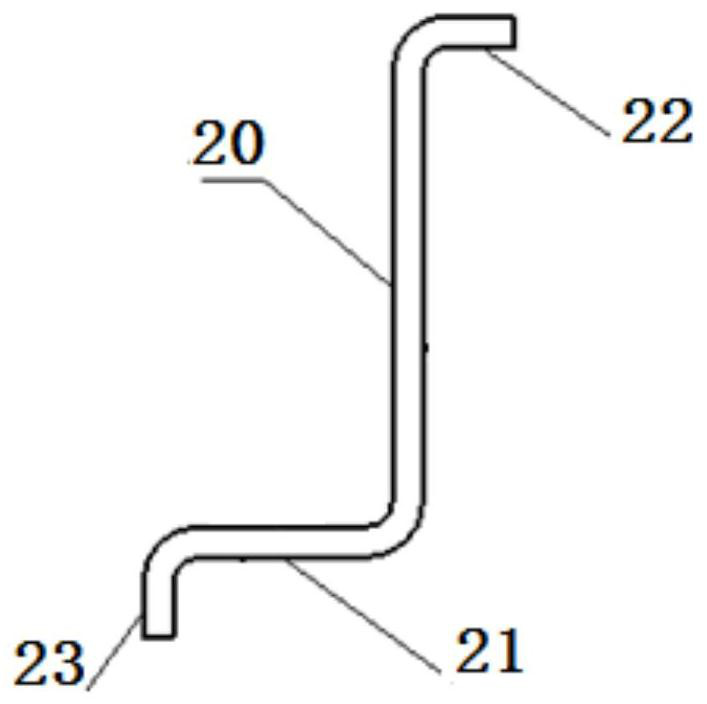

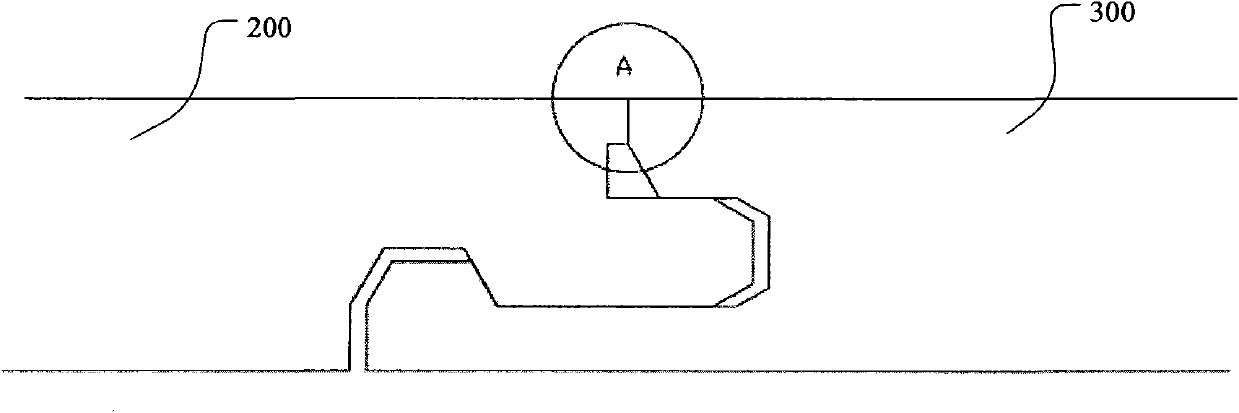

Overlay decorating plate

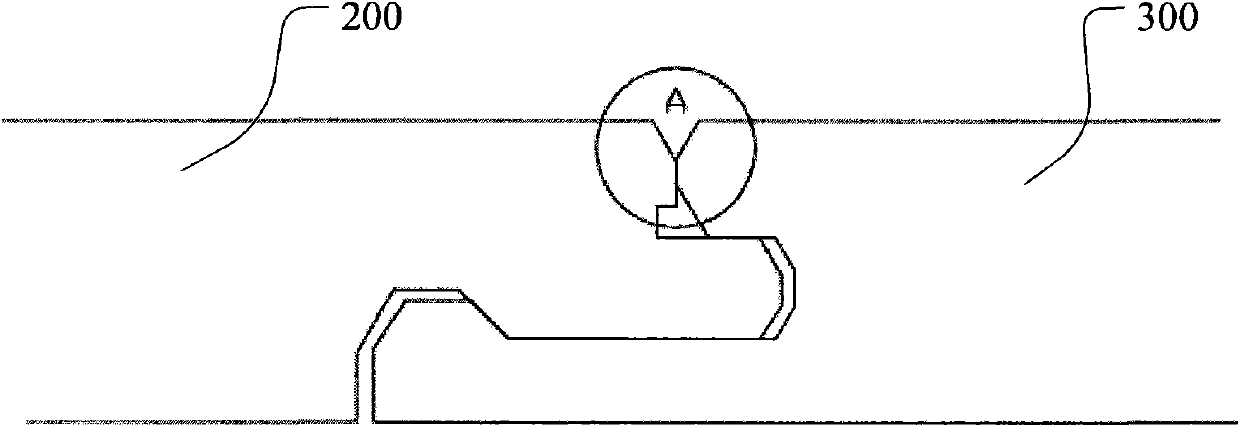

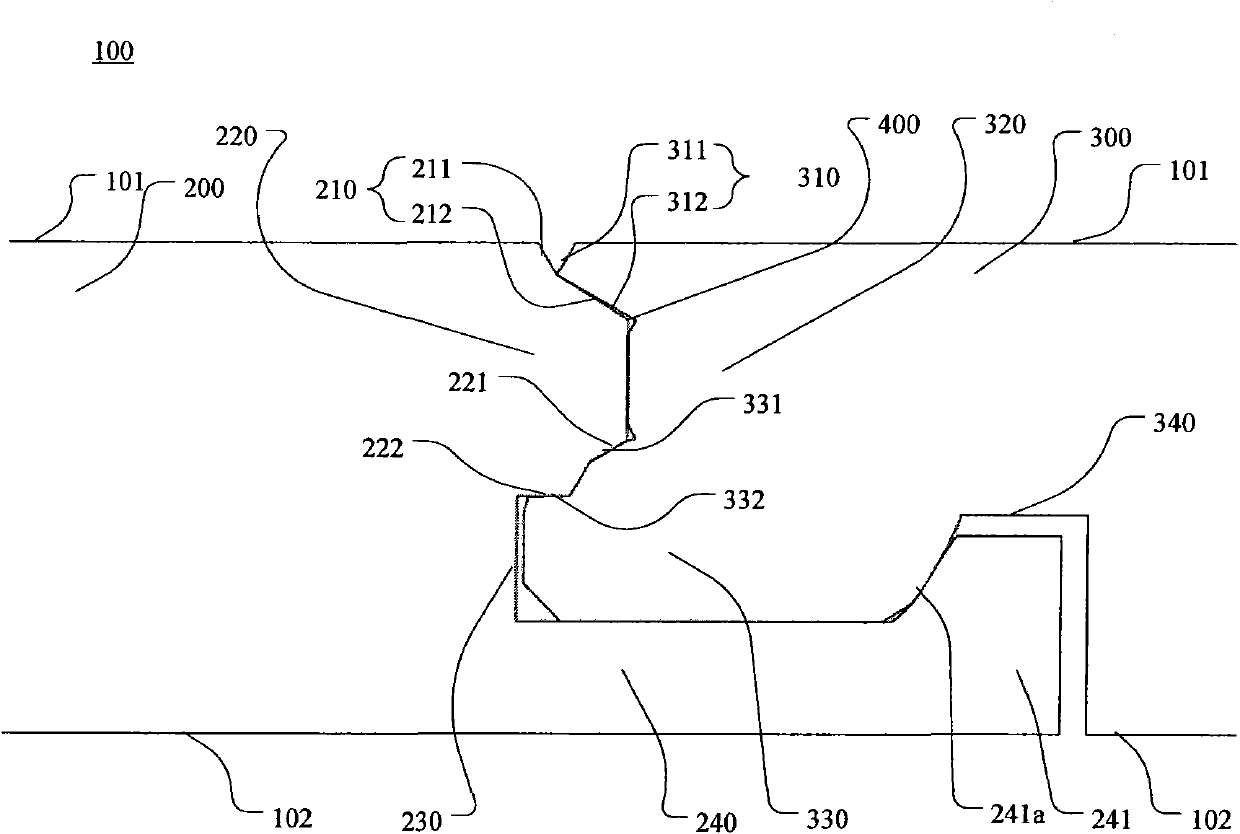

ActiveCN102373784ASimple structureImprove waterproof and dustproof performanceCovering/liningsFlooringSurface layerButt joint

The invention discloses an overlay decorating plate, which comprises a plate body, wherein the upper surface of the plate body is a surface layer, the lower surface of the plate body is a bottom layer, at least one edge of the plate body is provided with an upward connecting part, the other edge opposite to the edge is provided with a downward connecting part, and two overlay decorating plates are mutually connected through the upward connecting part and the downward connecting part; the downward connecting part at least comprises a first inclined plane, a first tenon and a first groove; the upward connecting part at least comprises a second inclined plane, a second groove and a second tenon; and when the two overlay decorating plates are connected with each other, the first tenon is in butt joint with the second groove, the first groove is in butt joint with the second tenon, an eudipleural groove is formed between a first upper surface and a second upper surface, and the first inclined plane and the second inclined plane are in a three-dimensional butt joint state. The overlay decorating plate disclosed by the invention has a simple structure, is convenient to splice, and is material-saving.

Owner:CHANGZHOU BEMATE HOME TECH CO LTD

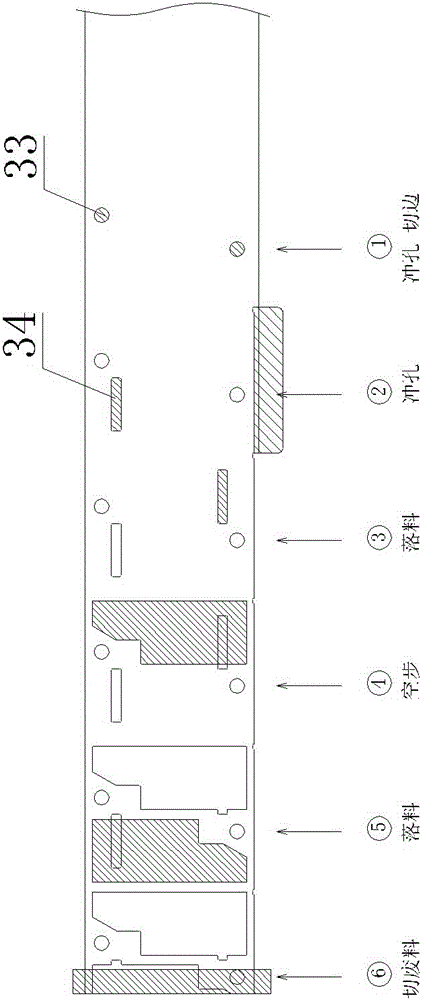

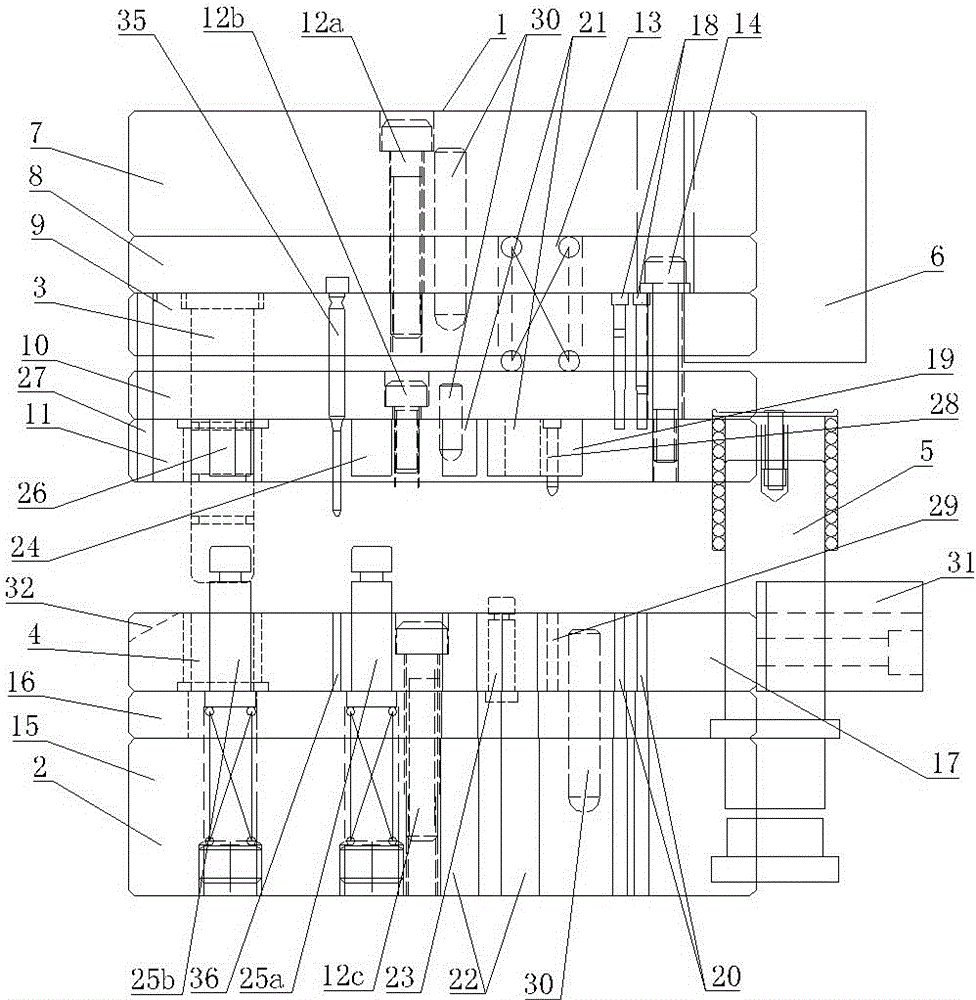

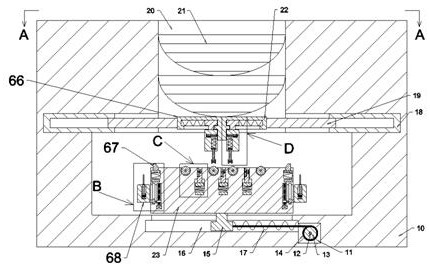

Stamping mould for motor connector

The invention provides a stamping mould for a motor connector, and the stamping mould can be used for continuously processing, is continuous in forming, is high in processing efficiency, is high in processing precision, is high in product qualification rate, and further can save raw materials. The stamping mould comprises an upper mould body and a lower mould body, wherein the upper mould body and the lower mould body are guided and closed in a matched mode through an inner guide post, an inner guide sleeve, an outer guide post and an outer guide sleeve; the upper mould body comprises an upper mould base as well as an upper gasket, an upper clamping plate, a stop plate and a stripper plate which are sequentially mounted under the upper mould base; the upper gasket is fixedly connected with the upper clamping plate through a fixed bolt; the stop plate is fixedly connected with the stripper plate through a fixed bolt; the stop plate and the stripper plate are mounted under the upper clamping plate through a spring and an equal-height sleeve; the lower mould body comprises a lower mould base as well as a lower gasket and a lower molding board which are sequentially mounted on the lower mould base; the lower molding board and the lower gasket are fixedly arranged on the lower mould base; and the upper mould body and the lower mould body are sequentially equipped with a positioning trimming mechanism, a punching mechanism, a first dropping mechanism and a second dropping mechanism in a plate conveying direction.

Owner:WUXI TAICHANG PRECISION MACHINERY CO LTD

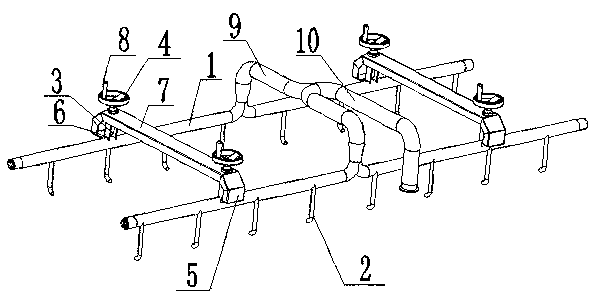

Cross-flow cleaning spray device

Owner:山东瑞帆果蔬机械科技有限公司

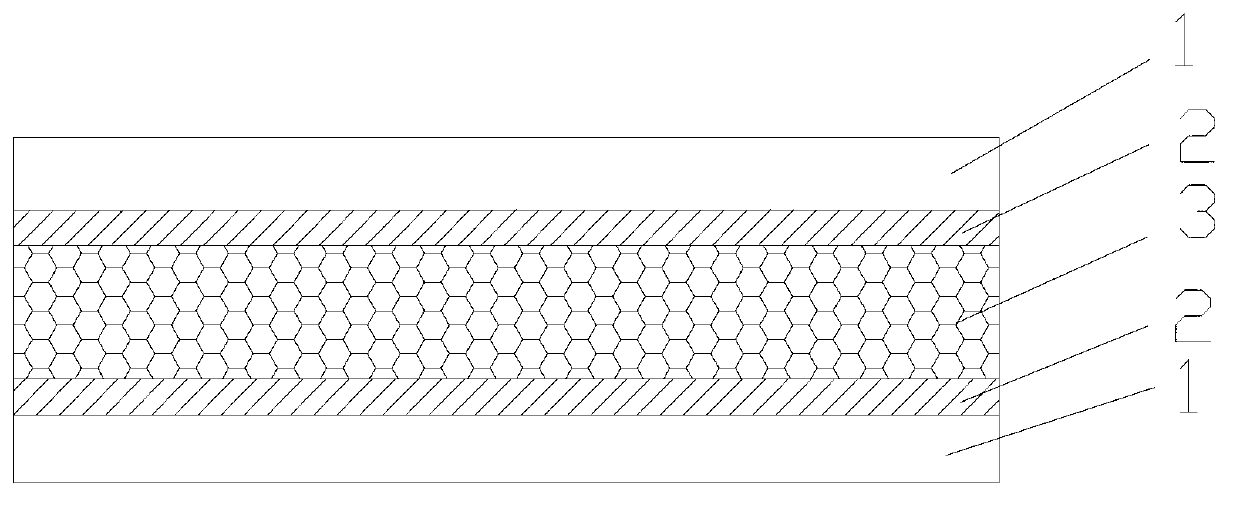

Honeycomb board furniture

The invention relates to honeycomb board furniture which is spliced by cellular boards. The honeycomb board comprises a honeycomb core, and a surface of the honeycomb core is usually covered with a decorative layer through a bonding layer. The honeycomb board is formed by adding the decorative layer, the bonding layer, the honeycomb core, the bonding layer and the decorative layer in sequence and bonding the layers together vacuumizing the gaps among the layers. Compared with prior wood furniture and artificial board furniture, the honeycomb board furniture is light and saving in board material, and achieves the same effects of attractiveness, firmness and smoothness as the wood furniture and the artificial board furniture. Further, furniture of metal honeycomb board structure has the effects of water resistance and fire resistance.

Owner:常州百美金属科技有限公司

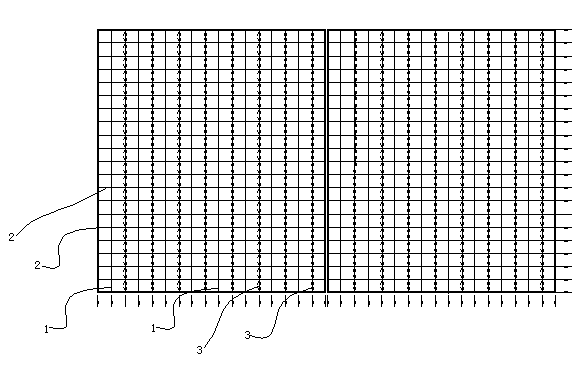

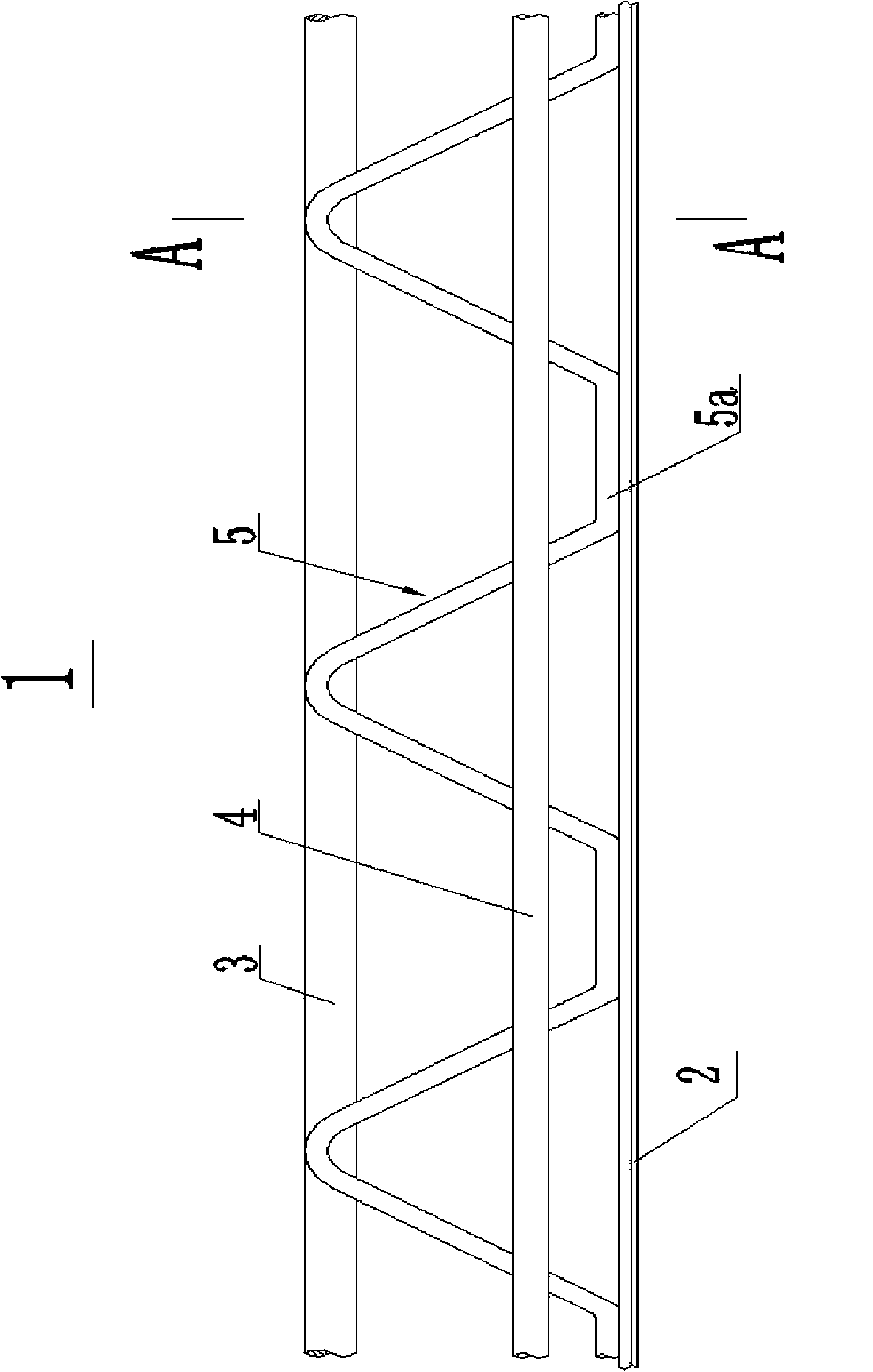

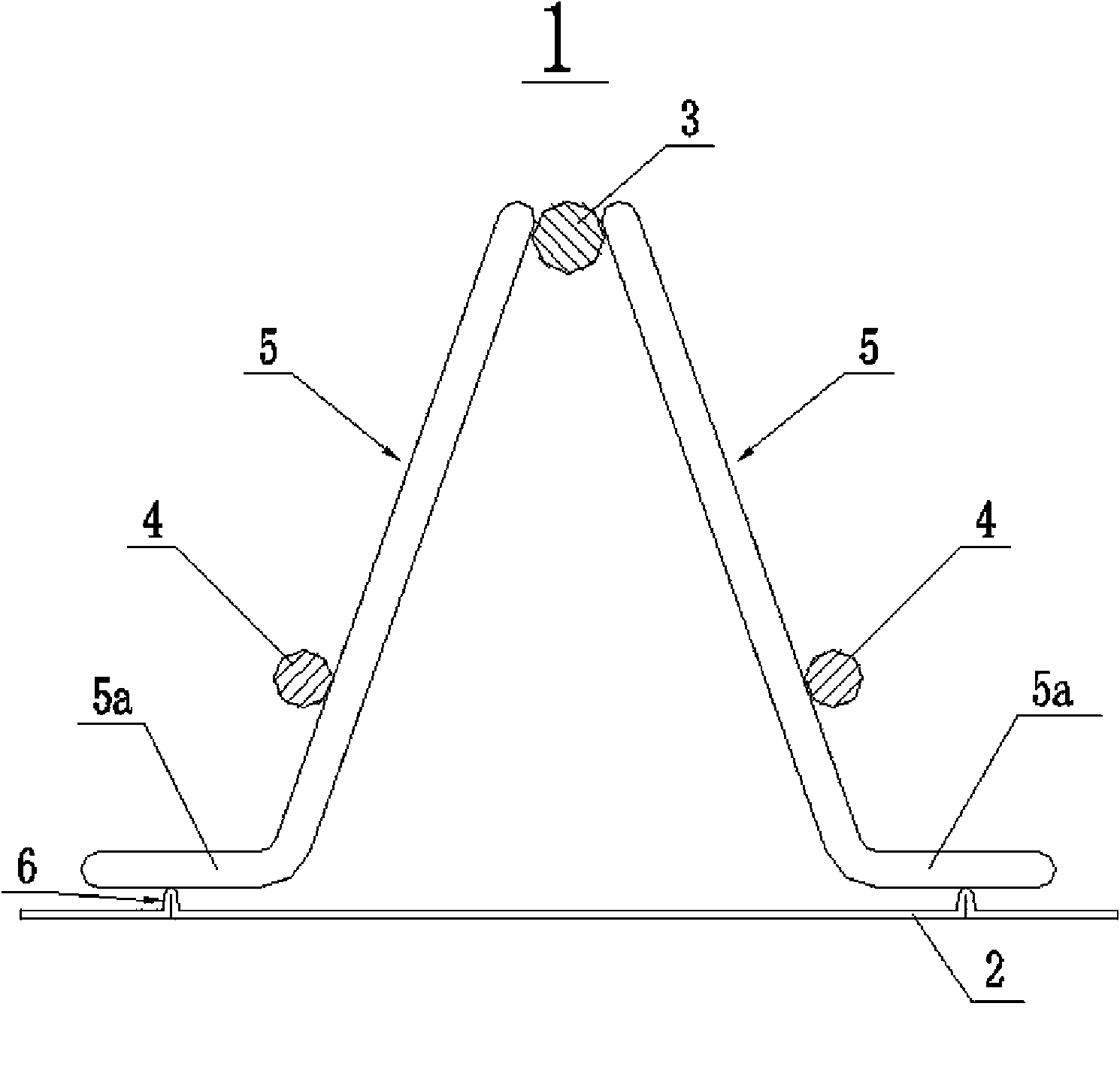

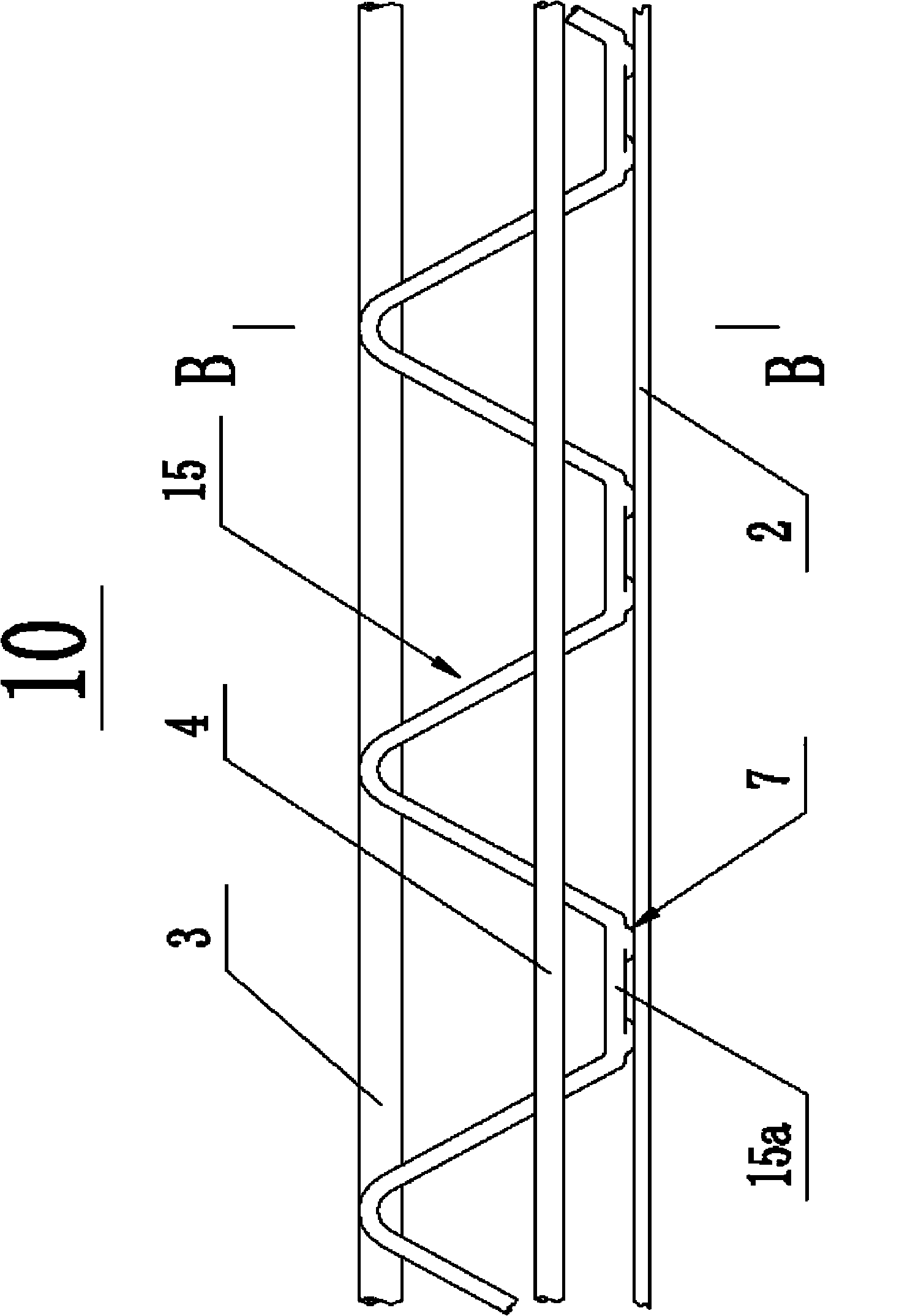

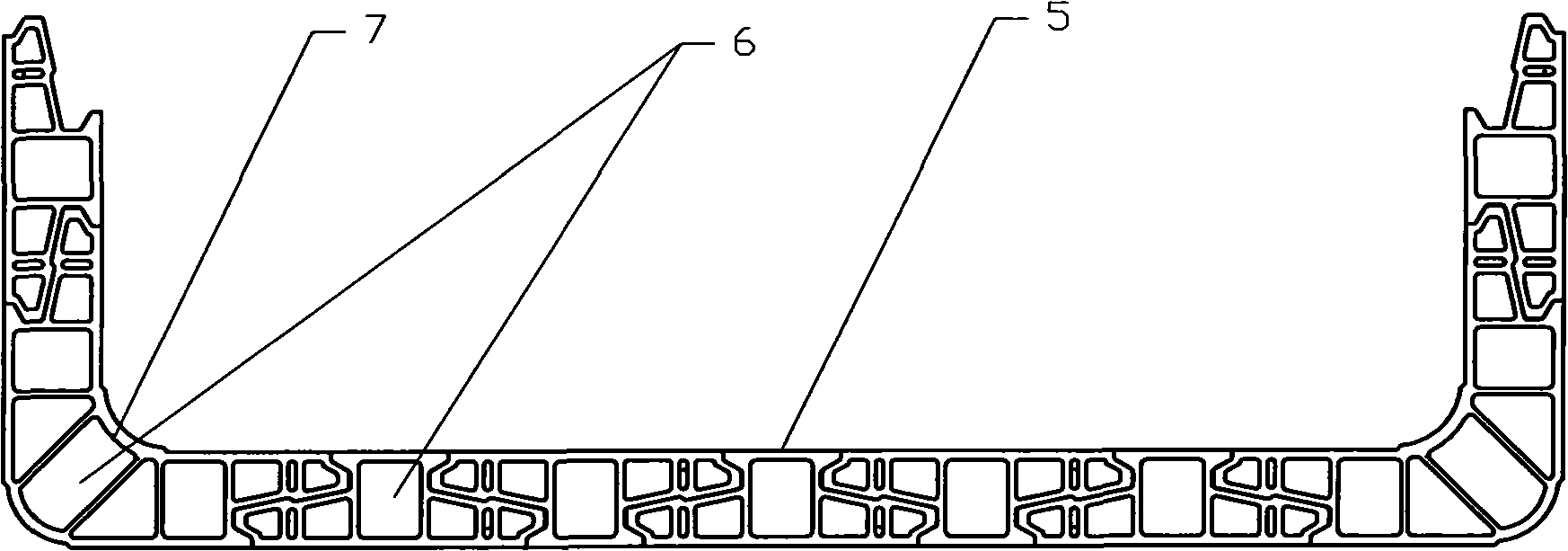

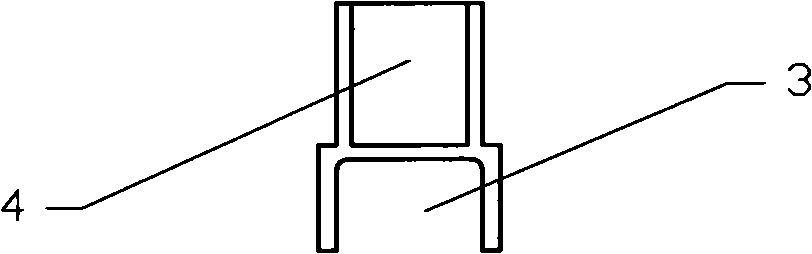

Reinforcement bar truss mould plate and welding process

ActiveCN101684673BHigh strengthIncrease productivityFloorsResistance welding apparatusMan-hourEngineering

The invention discloses a reinforcement bar truss mould plate and a welding process, wherein the reinforcement bar truss mould plate comprises a reinforcement bar truss and a bottom mould plate; the reinforcement bar truss comprises an upward spin reinforcement bar, a downward spin reinforcement bar and a web member reinforcement bar; and the bottom part of the web member reinforcement bar is parallel to the bottom mould plate and provided with a welding surface protruded toward the bottom mould plate, and the welding surface is welded on the plane of the bottom mould plate. The welding process comprises the following steps that: the bottom part of the web member reinforcement bar is bent to be parallel to the welded bottom mould plate; the bottom part of the web member reinforcement bar is downward pressed to from the welding surface; the top end parts of the two web member reinforcement bars are welded on both sides of the upward spin reinforcement bar; the downward spin reinforcement bars are welded on the symmetrical parts on the outer sides of the two web member reinforcement bars and below the upward spin reinforcement bar respectively; and the welding surface on the bottom part of the web member reinforcement bar is welded on the plane of the bottom mould plate. The reinforcement bar truss mould plate and the welding process have the advantages that: because the web member reinforcement bar and the bottom mould plate are of surface contact, the after-welding strength is improved by three times; the welding process is easily mastered, and the defects of puncturing the bottom mould plate and leaking concrete mortar are overcome; and because the bottom mould plate does not need an angle-type arc ribs, the plates, man-hours and labor are saved, and the production efficiency is improved by 40 percent.

Owner:TJK MACHINERY TIANJIN

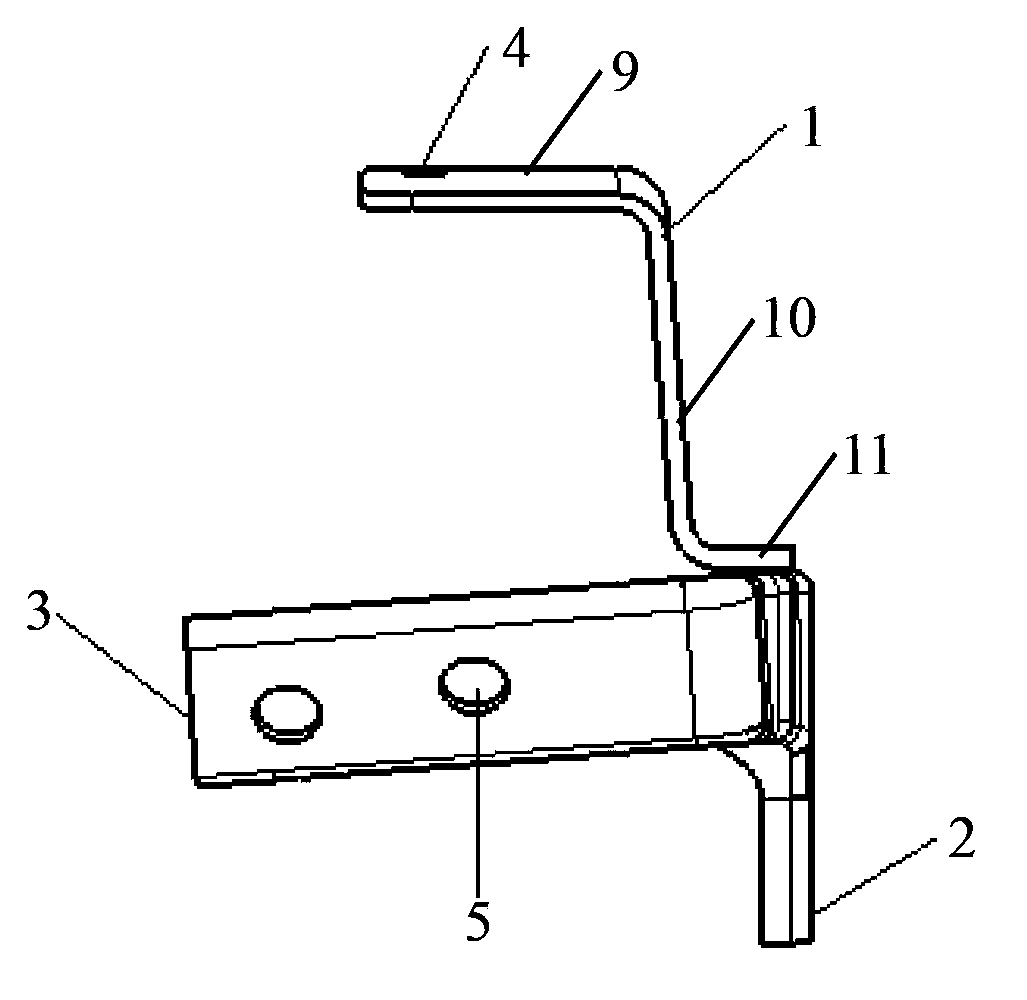

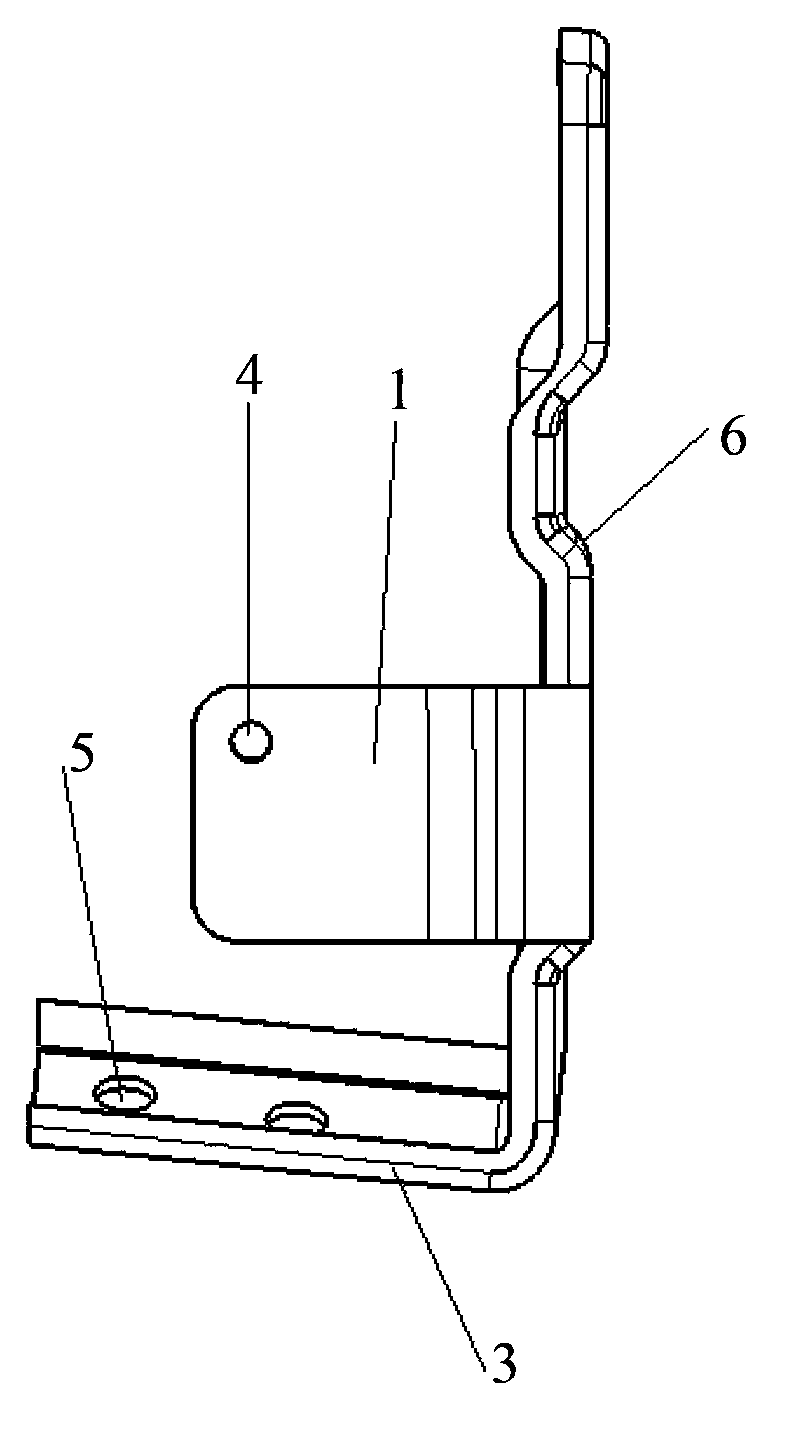

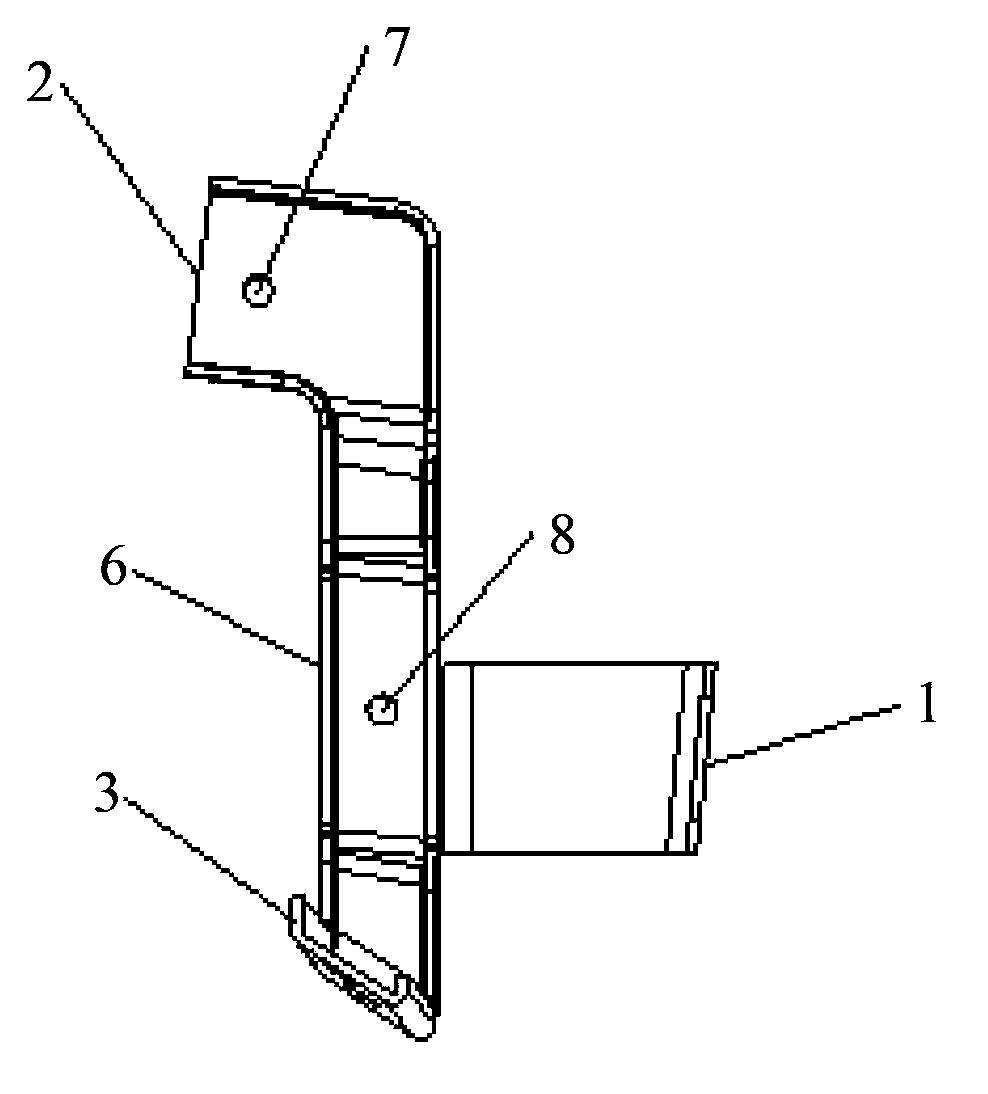

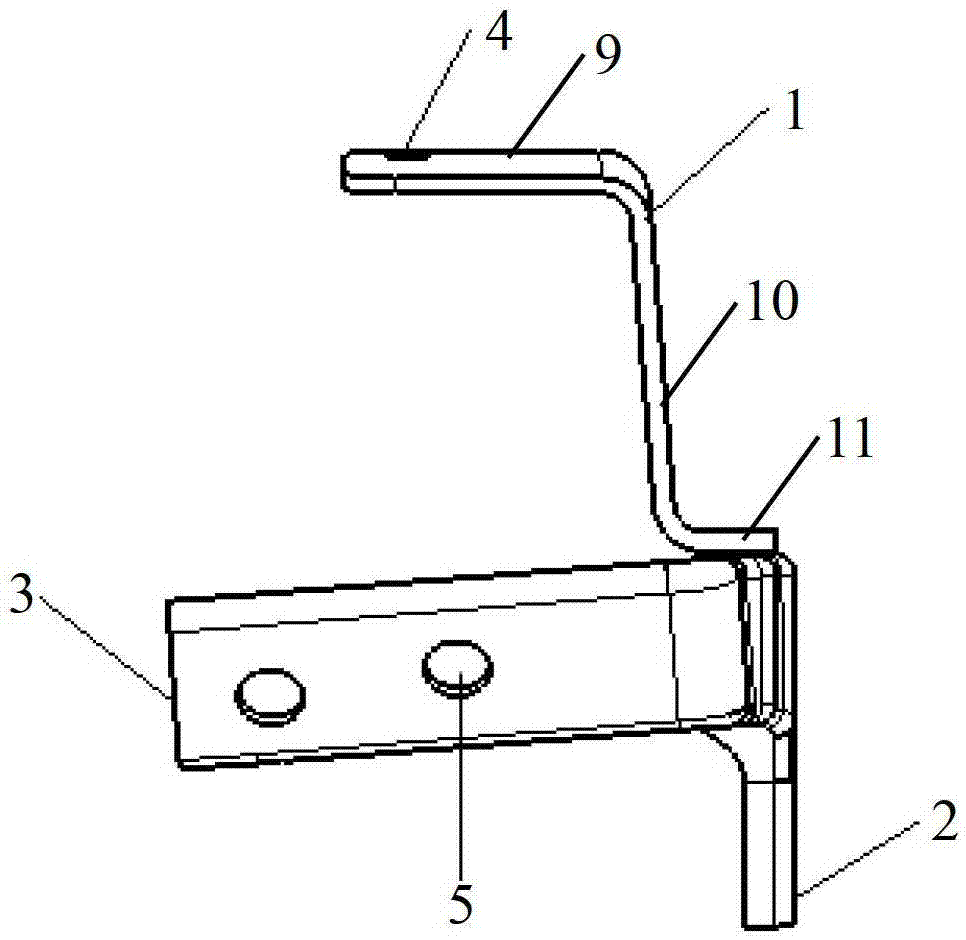

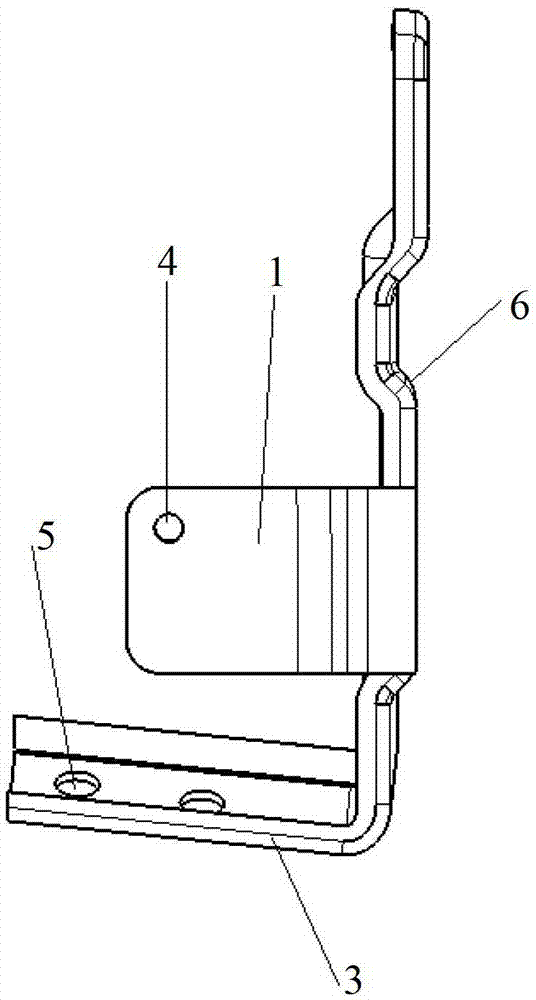

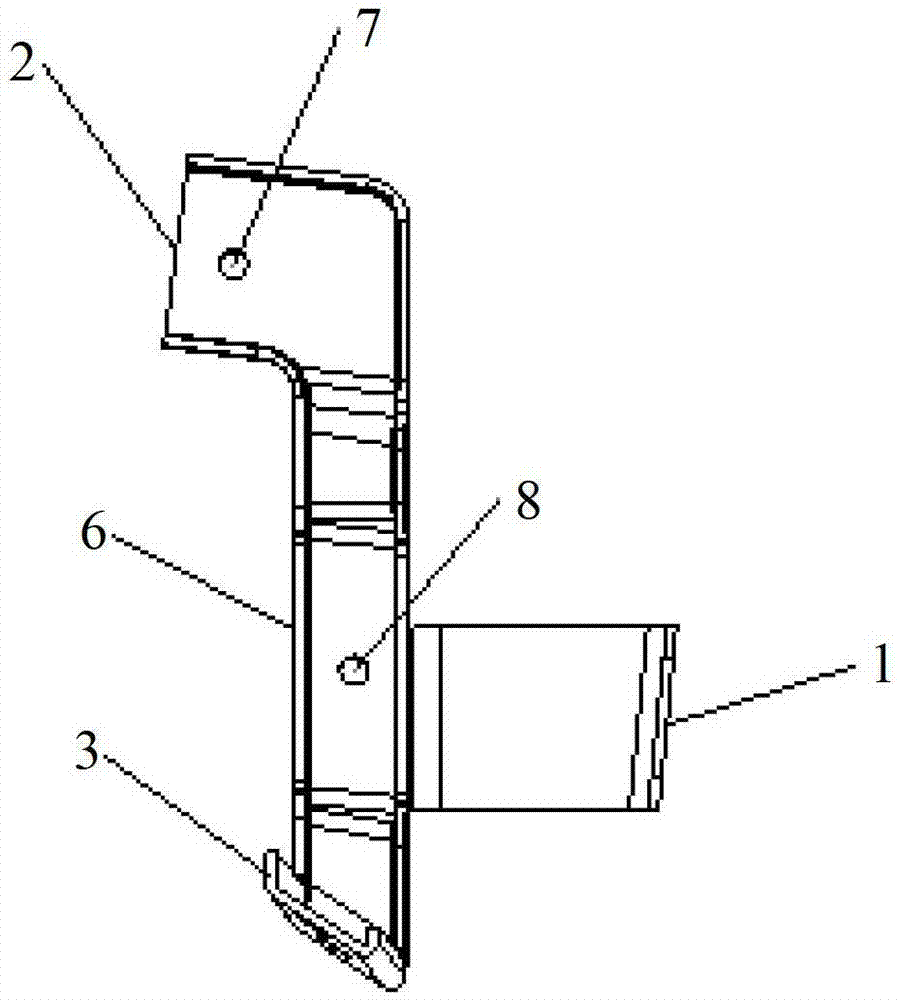

Combined supporting frame

ActiveCN103661620AEasy cut designSave boardSuperstructure subunitsDashboardsEngineeringMechanical engineering

The invention relates to a vehicle accessory technology, and discloses a combined supporting frame. The combined supporting frame a first supporting frame for fixing a secondary instrument board, and a second supporting frame which is used for fixing the secondary instrument board and a protective board at the inner side of a cab and is installed on the floor of the cab, wherein the first supporting frame and the second supporting frame are independently formed and connected in a welding mode. According to the combined supporting frame, the first supporting frame which is used for fixing the secondary instrument board, and the second supporting frame which is used for fixing the secondary instrument board and the protective board at the inner side of the cab and is installed on the floor of the cab are independently formed and connected in the welding mode, and therefore the first supporting frame and the second supporting frame are cut and designed conveniently, boards are saved, and cost is lowered.

Owner:BEIQI FOTON MOTOR CO LTD

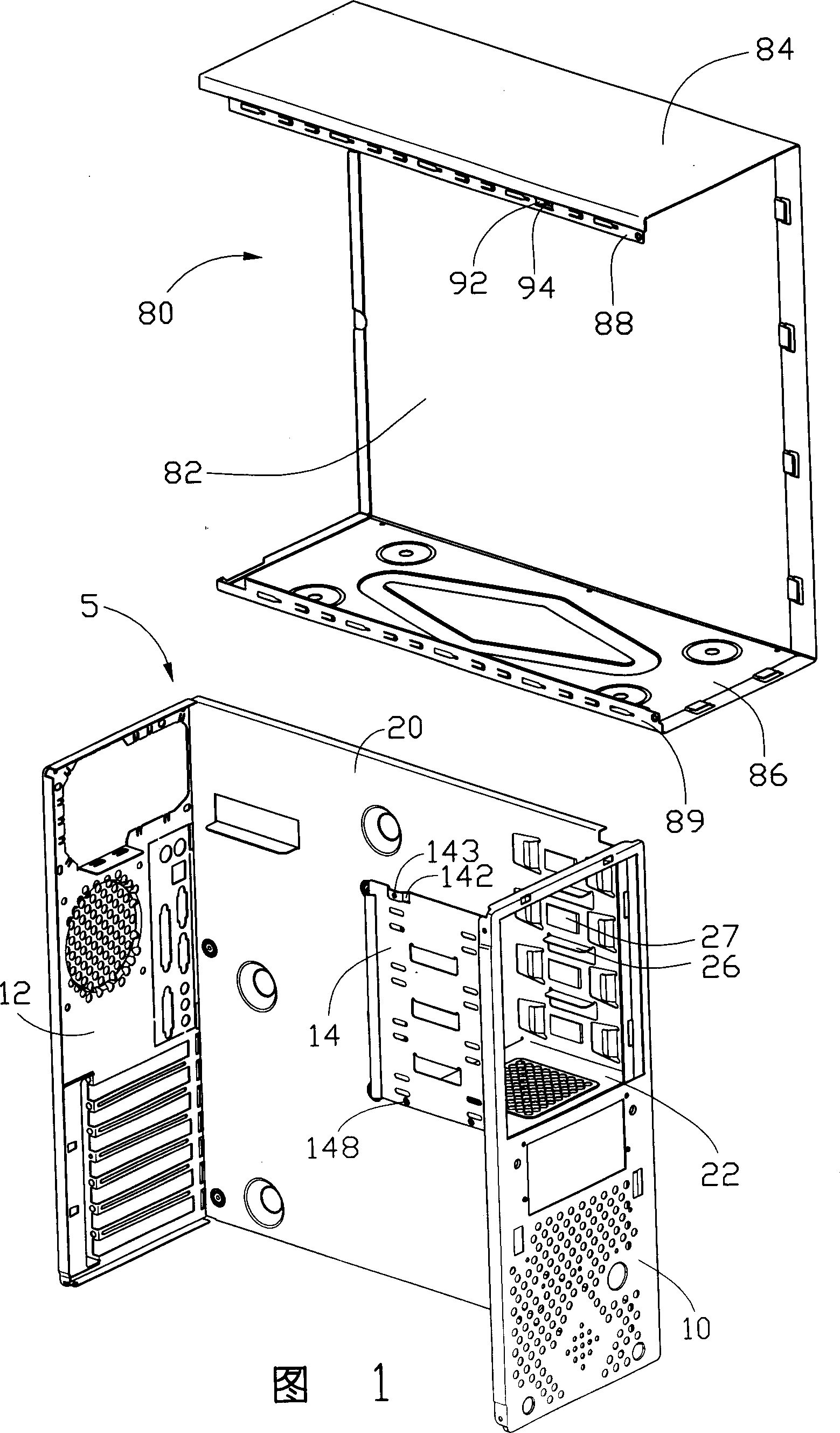

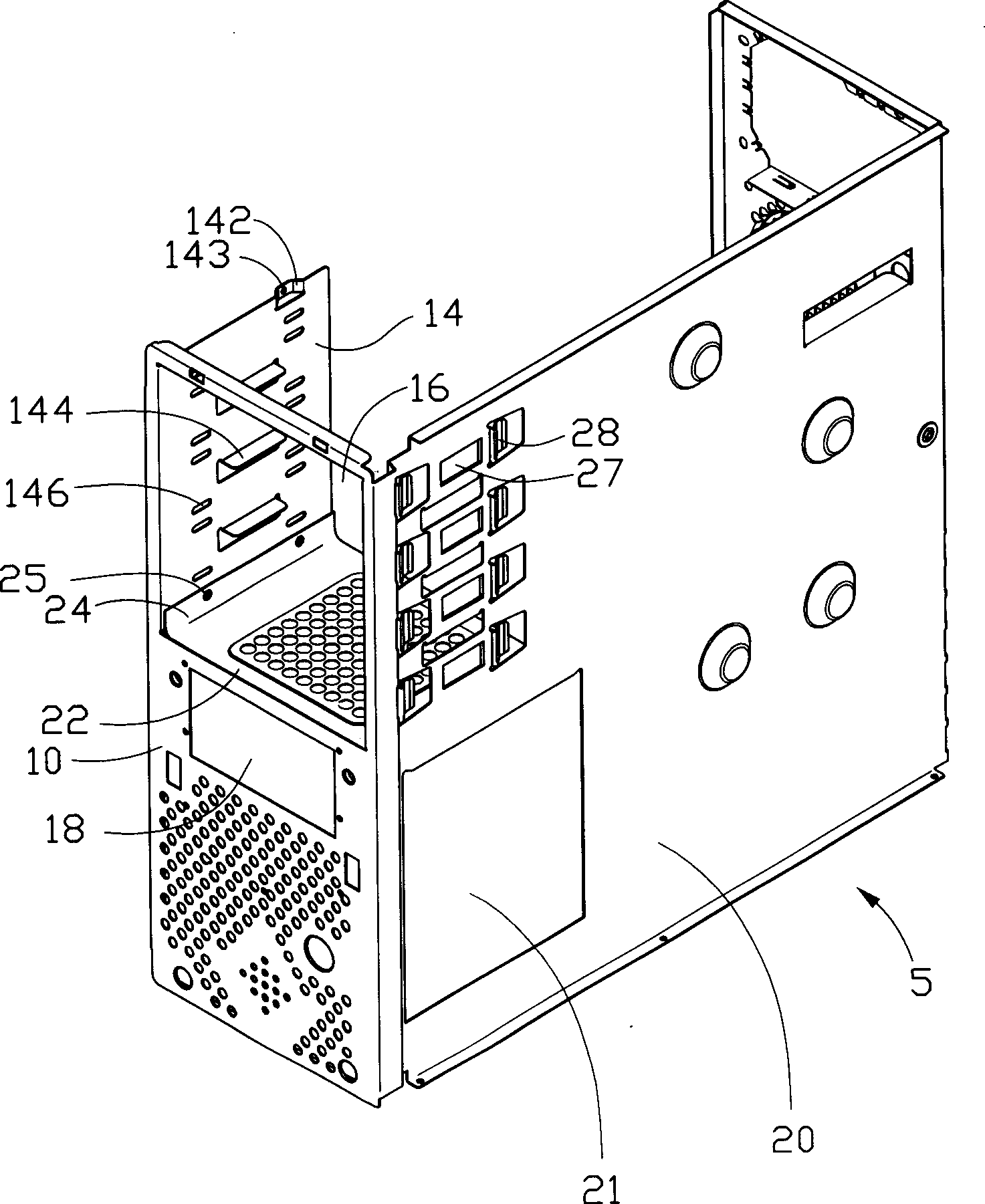

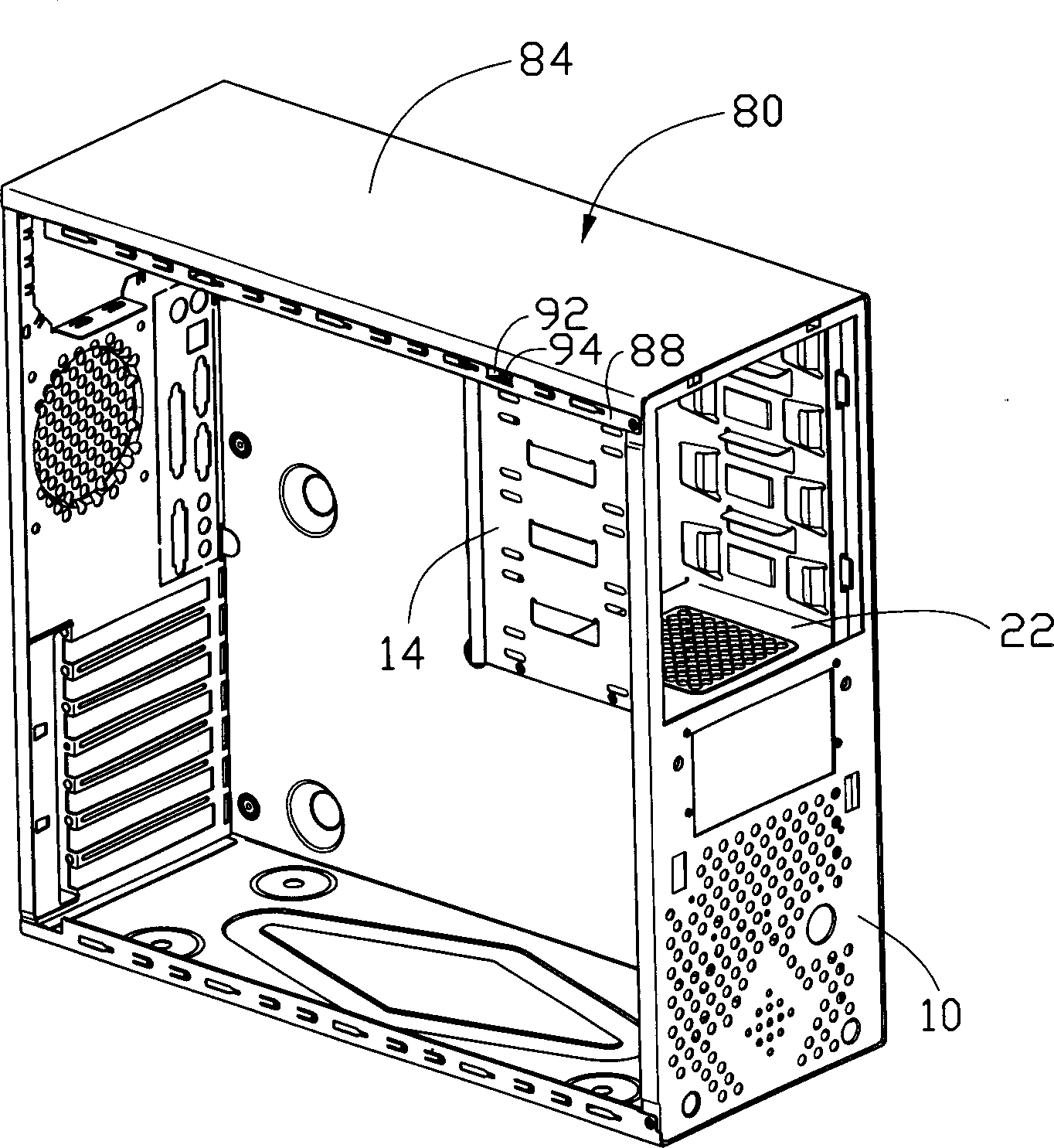

Computer shell body

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

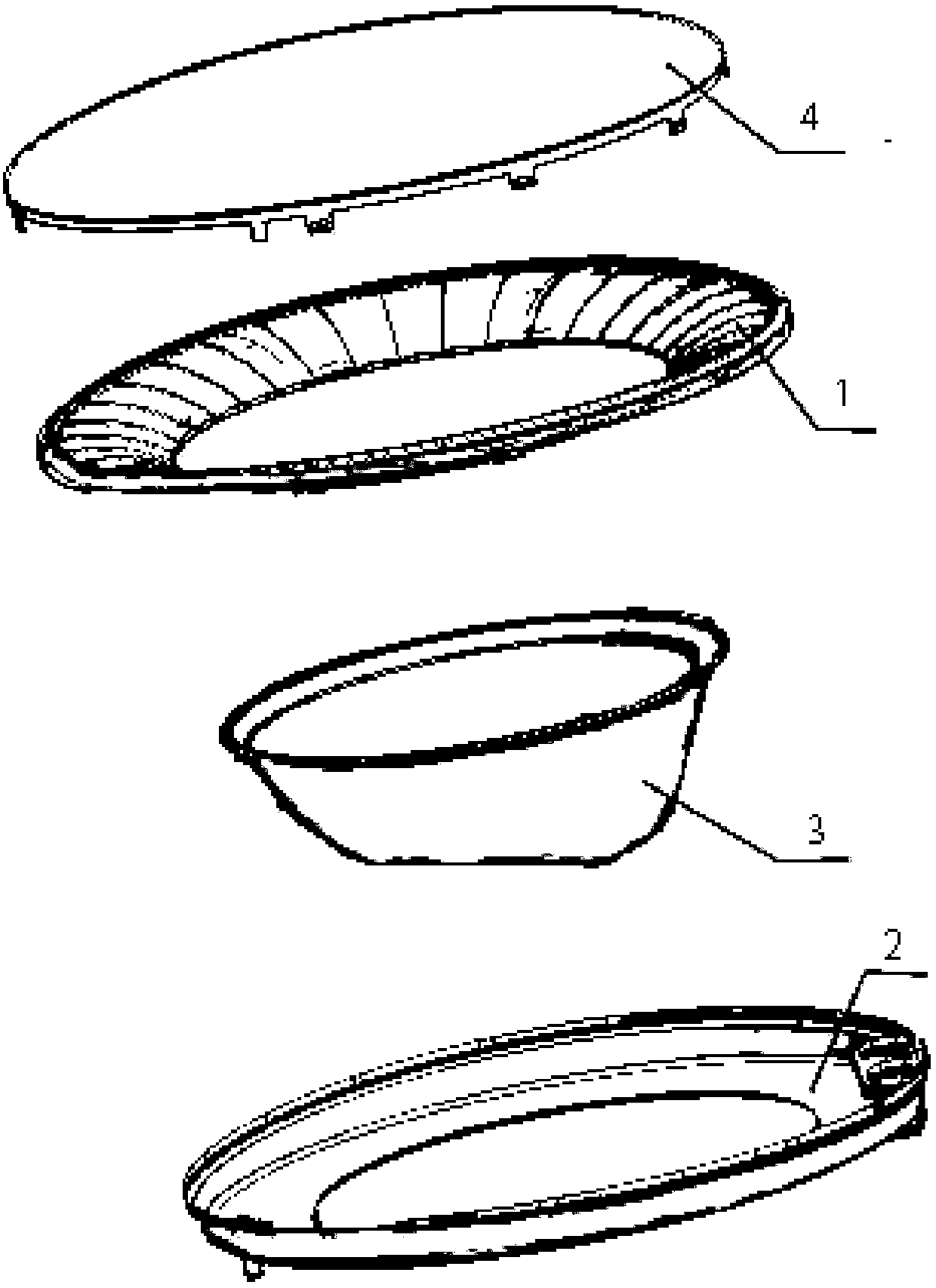

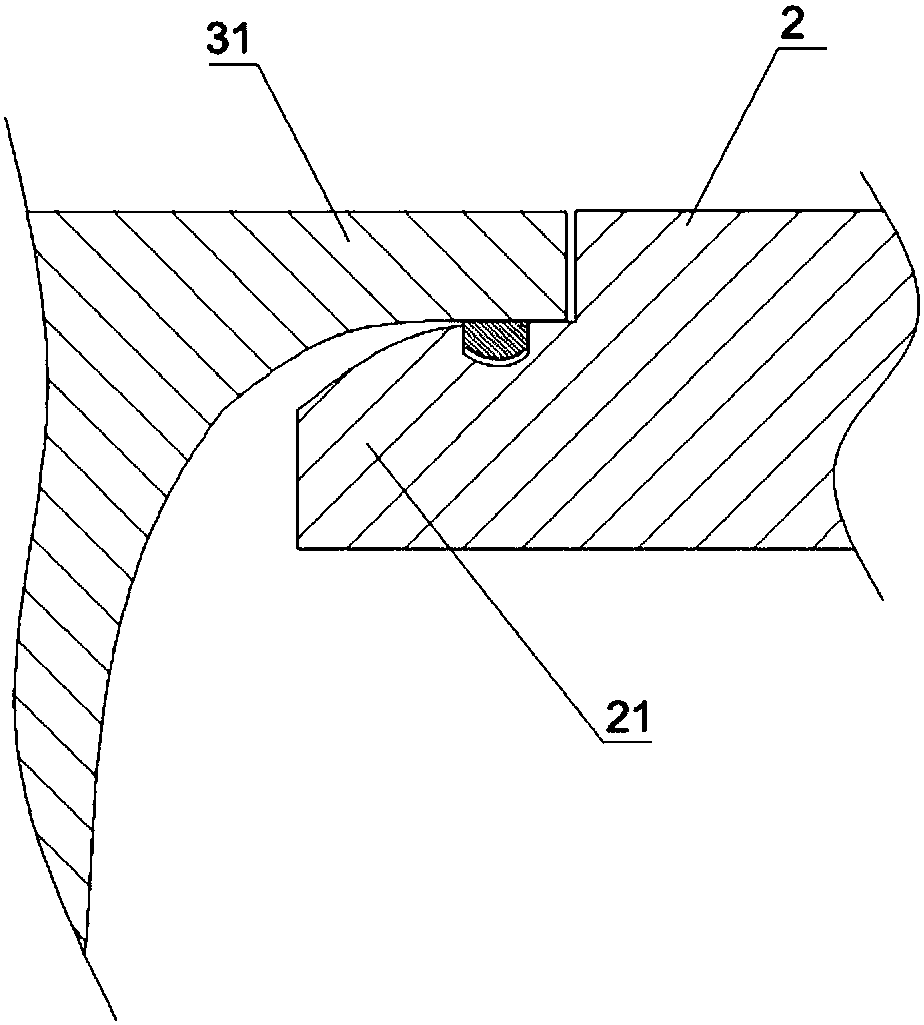

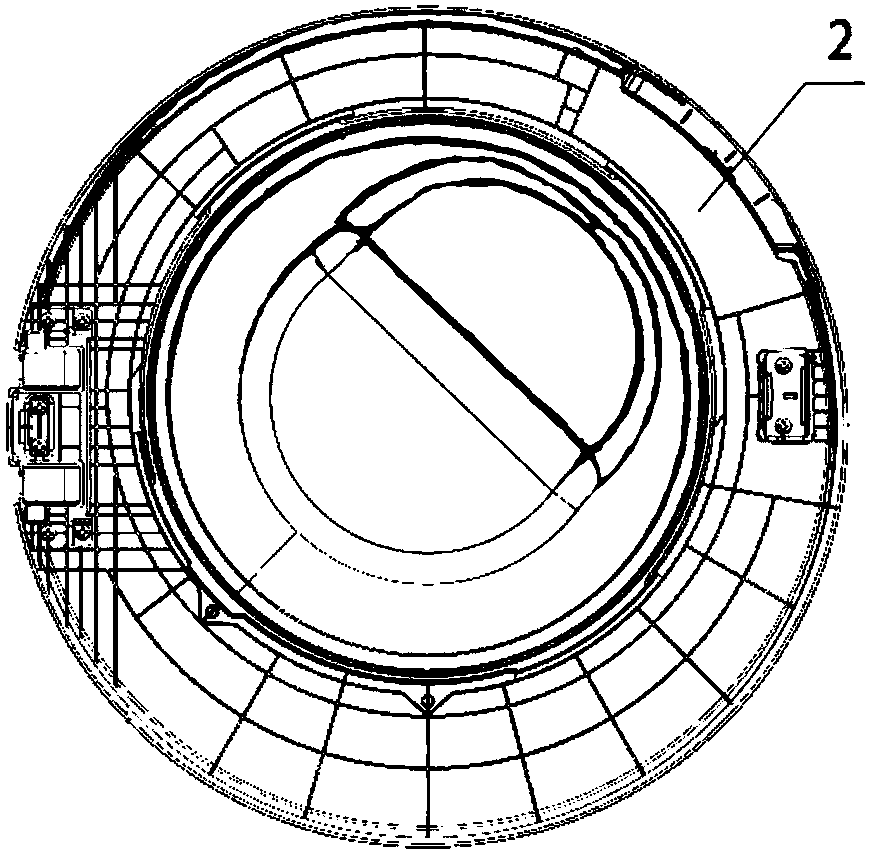

Glass window of washing machine, processing method and washing machine

PendingCN109518433ALow costSave boardOther washing machinesTextiles and paperGlass windowPulp and paper industry

The invention relates to a glass window of a washing machine, a processing method and the washing machine. The glass window comprises an outer frame, an inner frame and viewing glass, the viewing glass is arranged between the outer frame and the inner frame, and a sealing space defined by the outer frame, the viewing glass and the inner frame is filled with a foaming material. According to the glass window, through a foaming fixing mode, a middle frame is omitted, any new component is not added, and the cost is reduced. A screw does not need to be fixed between the inner frame and the outer frame, a buckle structure of the outer frame is omitted, a mold structure is simplified, and the production efficiency of workers is improved.

Owner:QINGDAO HAIER MOLDS

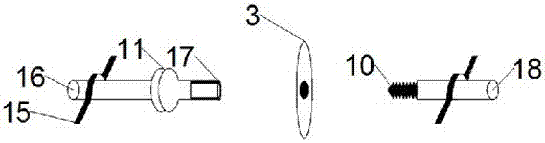

Mechanically-jointed integrated board technique for natural width beveled edge board

InactiveCN102218760AImprove stitching qualityEasy to operateOther plywood/veneer working apparatusWood veneer joiningMaterial consumptionWood plank

The invention relates to a mechanically-jointed integrated board technique for natural width beveled edge board, which concretely comprises the following working procedures: 1), original wood boards with barks and natural width are mechanically sawn into dimension boards with standard obliquity by an edging machine along two long beveled edges of the original wood boards; 2), a plurality of dimension boards sawn through the procedure 1) are primarily arranged according to a sequence of big and small ends as well as front and back surfaces in a staggered way; then the dimension boards primarily arranged are jointed into rectangular board blocks by glue; 3) the rectangular board blocks in the procedure 2) are divided into a plurality of semi-finished boards with four trim and smooth sides and uniform specifications by a cutting machine; and 4) the plurality of semi-finished boards in procedure 3) are jointed to form an integrated board. The mechanically-jointed integrated board technique for the natural width beveled edge board can be adopted for effectively preventing multiple material consumption phenomena in the current mechanically-jointed integrated board technique from happening, and can also increase the jointing area and is beneficial to improving the jointing quality of the integrated board.

Owner:周富海

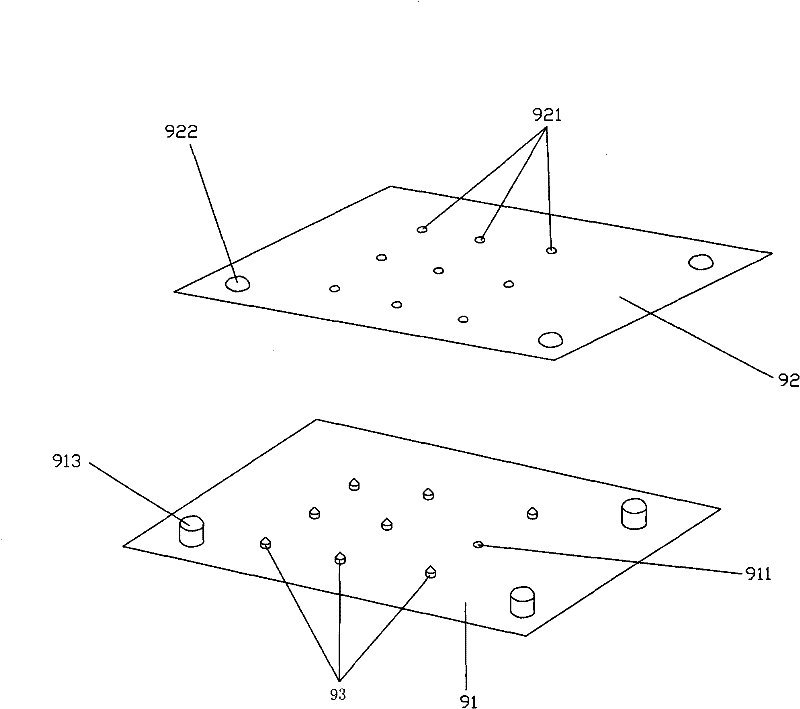

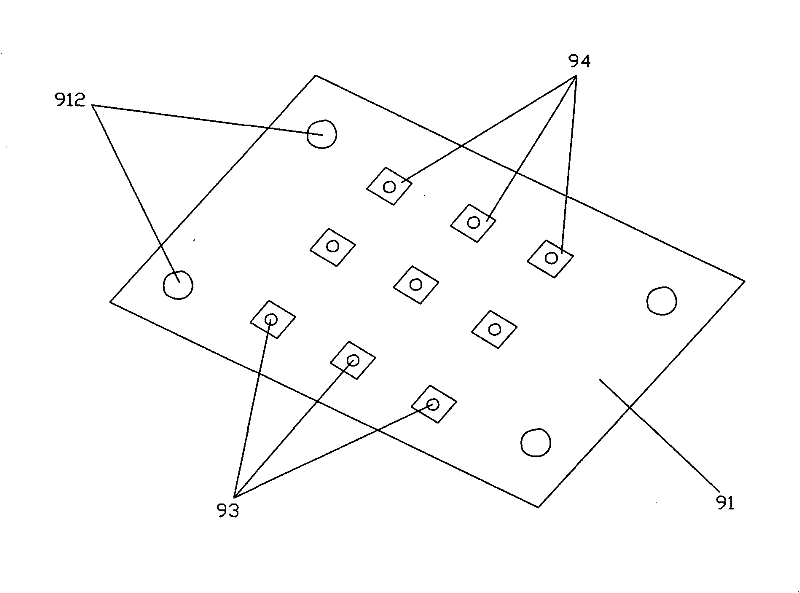

Manufacturing method of nail bed for PCB solder-mask printing

InactiveCN102105022BEasy to manufactureFast preparationNon-metallic protective coating applicationSolder maskEngineering

Owner:SHENNAN CIRCUITS

Preparation method of mixed welding and cutting gas

The invention discloses a mixed welding and cutting gas preparation method which comprises the following components in percentage by mass: 50%-75% of acetylene gas, 20%-40% of propane, 0.1%-1% of hydrogen peroxide, 0.5%-1% of sodium bicarbonate, 0.2%-0.7% of a polymeric iron solution and 5%-10% of liquefied petroleum gas. The method comprises the following specific operation steps: uniformly mixing sodium bicarbonate and hydrogen peroxide, fully dissolving the sodium bicarbonate and the hydrogen peroxide to prepare a mixed solution, and performing gas-liquid mixing on gas and liquid of the mixed solution; adding a polymeric iron solution into the mixed solution, and uniformly mixing to obtain a new mixture; injecting a proper amount of new mixture into an empty acetylene gas cylinder; filling propane, liquefied petroleum gas and acetylene gas into the acetylene gas cylinder according to the proportion, and fully mixing; and warehousing after passing the inspection. Compared with the prior art, the preparation method has the advantages that all components in the preparation process are common chemicals, and the preparation method is low in cost, safe, energy-saving, environment-friendly and convenient to use.

Owner:严鹏

Combination bracket

ActiveCN103661620BEasy cut designSave boardSuperstructure subunitsDashboardsEngineeringMechanical engineering

The invention relates to a vehicle accessory technology, and discloses a combined supporting frame. The combined supporting frame a first supporting frame for fixing a secondary instrument board, and a second supporting frame which is used for fixing the secondary instrument board and a protective board at the inner side of a cab and is installed on the floor of the cab, wherein the first supporting frame and the second supporting frame are independently formed and connected in a welding mode. According to the combined supporting frame, the first supporting frame which is used for fixing the secondary instrument board, and the second supporting frame which is used for fixing the secondary instrument board and the protective board at the inner side of the cab and is installed on the floor of the cab are independently formed and connected in the welding mode, and therefore the first supporting frame and the second supporting frame are cut and designed conveniently, boards are saved, and cost is lowered.

Owner:BEIQI FOTON MOTOR CO LTD

Installation method of fireproof plate at curved surface position of air pipe

InactiveCN113550456AReduce dosageConvenient ArrangementBuilding material handlingVertical ductsLine tubingStructural engineering

The invention discloses an installation method of a fireproof plate at a curved surface position of an air pipe. The fireproof plate is usually installed at an elbow, a climbing position and a curved surface air pipe position in a broken-line-shaped mode, the method is poor in attractiveness, high in space occupancy, unfavorable for arrangement of multi-specialty comprehensive pipelines and capable of causing collision, and plates can be wasted. In order to overcome the defects, a method of breaking up the whole into parts is adopted for the whole curved surface position of an air pipe by utilizing a calculus principle, the fireproof plate is cut into a narrow strip shape, the section is polished into an oblique angle, the fireproof plate is tightly connected during splicing, the curved surface is broken up the whole into the parts and is divided into a plurality of straight line segments, and the straight line segments are used for fitting an arc; the purposes of attractive appearance, low space occupancy rate and plate saving are achieved.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

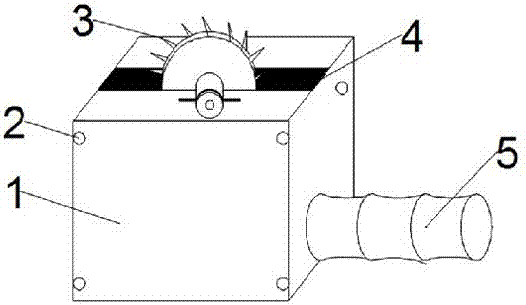

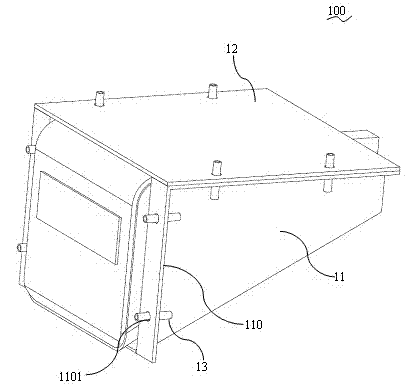

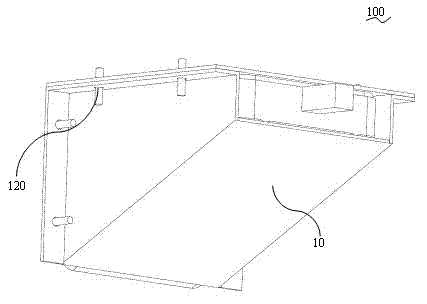

Dust collection device of electric saw for home decoration

InactiveCN107214789AReduce decoration costsHarm reductionBark-zones/chip/dust/waste removalElectricityEnergy consumption

The invention discloses a dust collection device for an electric saw for home decoration. The dust collection device for the electric saw for home decoration comprises a box. Six faces of the box are all provided with bolts. A saw blade fixing shaft I is arranged on the upper surface of the box. An assembly fixing block is arranged on the saw blade fixing shaft I. A belt pulley I and a saw blade are arranged on the saw blade fixing shaft I. A motor and a dust collection draught fan are arranged in the box. A belt pulley II is arranged on the motor. A belt pulley III is arranged on the dust collection draught fan. Due to the fact that the dust collection draught fan is arranged, a large amount of saw dust generated when carpenter cuts boards is collected by the dust collection draught fan, and dust pollution is reduced. Due to the fact that all the faces of the box are provided with the bolts, the box is convenient to assemble and disassemble, and then the box is convenient to carry. Due to the fact that the motor both supplies a power source for the dust collection draught fan and the saw blade fixing shaft, one motor has multiple functions; and in this way, the electricity consumption is reduced, and the dead load of the box is reduced. Hence, the dust collection device for the electric saw for home decoration has the advantages of being simple in structure, convenient to carry, low in energy consumption and the like and is worthy of popularization.

Owner:黎应勇

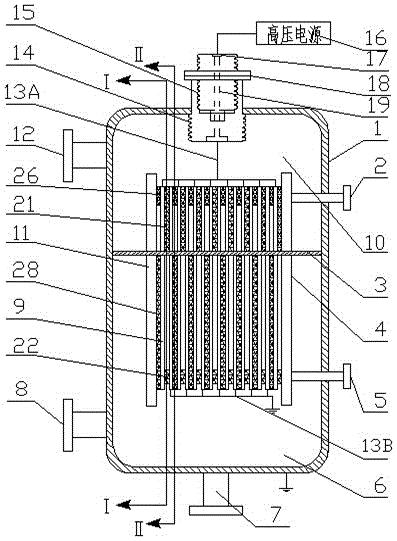

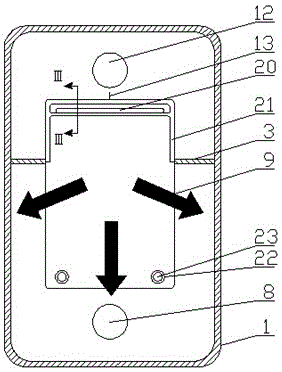

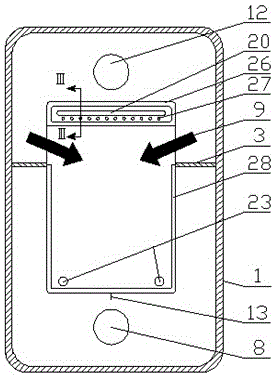

An electric field enhanced plate type falling film evaporation device and method thereof

The invention discloses an electric field enhanced plate type falling film evaporation device and a method. The device mainly comprises a high-voltage power supply, electrode wires, an insulation device, stainless steel plate sheets, insulation sealing gaskets, an insulation support partition and a housing. The adjacent stainless steel plate sheets of the plate type evaporation device are connected with the high-voltage power supply and earthed via the electrode wires respectively, so that a high-voltage electric field is formed; liquid is distributed on an evaporation side through small holes to form falling film flow; steam enters a condensation side of the plate type evaporation device through a plate-to-plate side edge to condense and release latent heat to heat the liquid on the evaporation side; the high-voltage electric field between the stainless steel plate sheets can further strengthen an evaporation process; the evaporated liquid is subjected to steam-liquid separation in a steam-liquid separation space; and the secondary steam and concentrated liquid can be further utilized. According to the device and the method, an evaporation enhancement effect of the high-voltage electric field is utilized, and the high-voltage electric field is formed between the plate sheets of the plate type falling film evaporation device by reasonable arrangement of the electrode wires, so that a heat transfer coefficient can be increased, the heat exchange area is reduced, plates are saved, and energy consumption is reduced.

Owner:ZHEJIANG UNIV

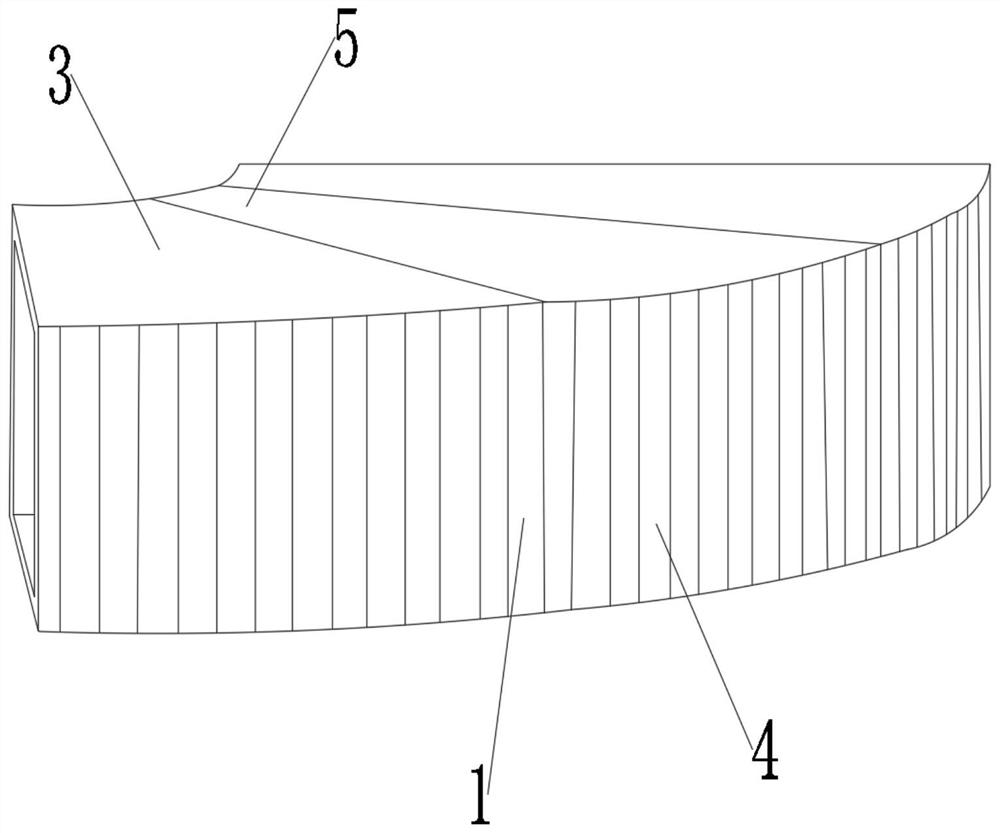

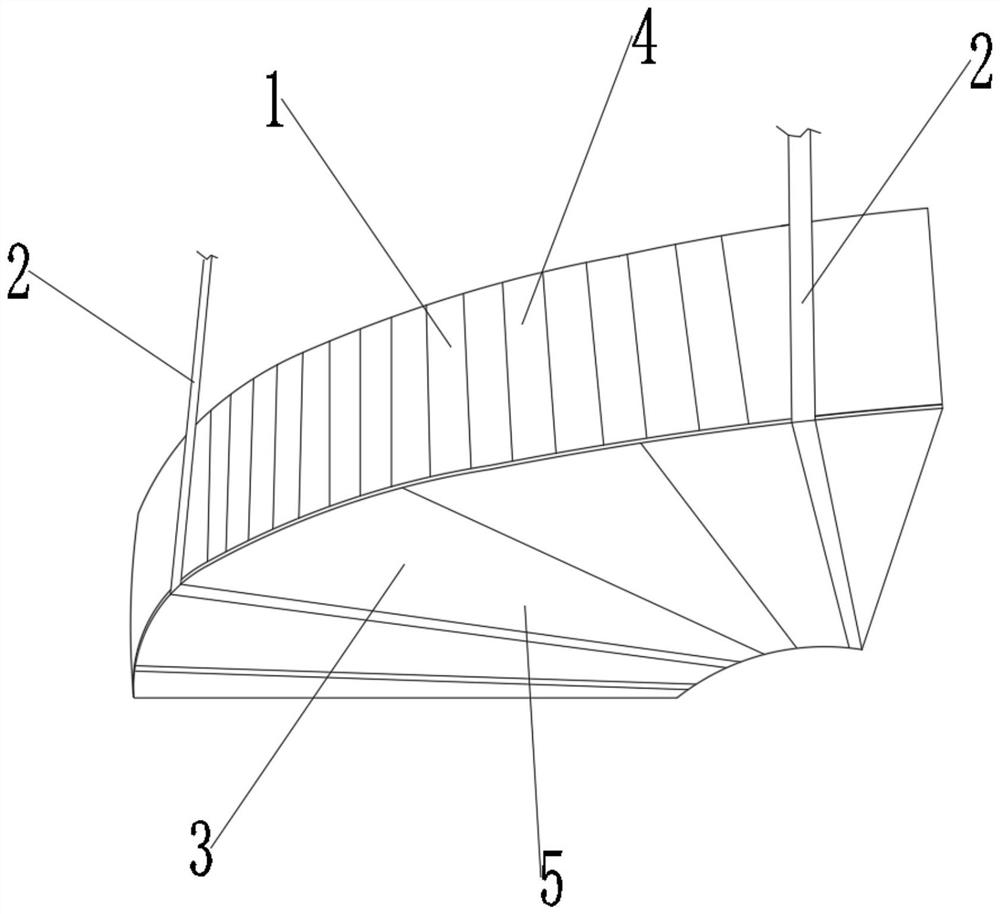

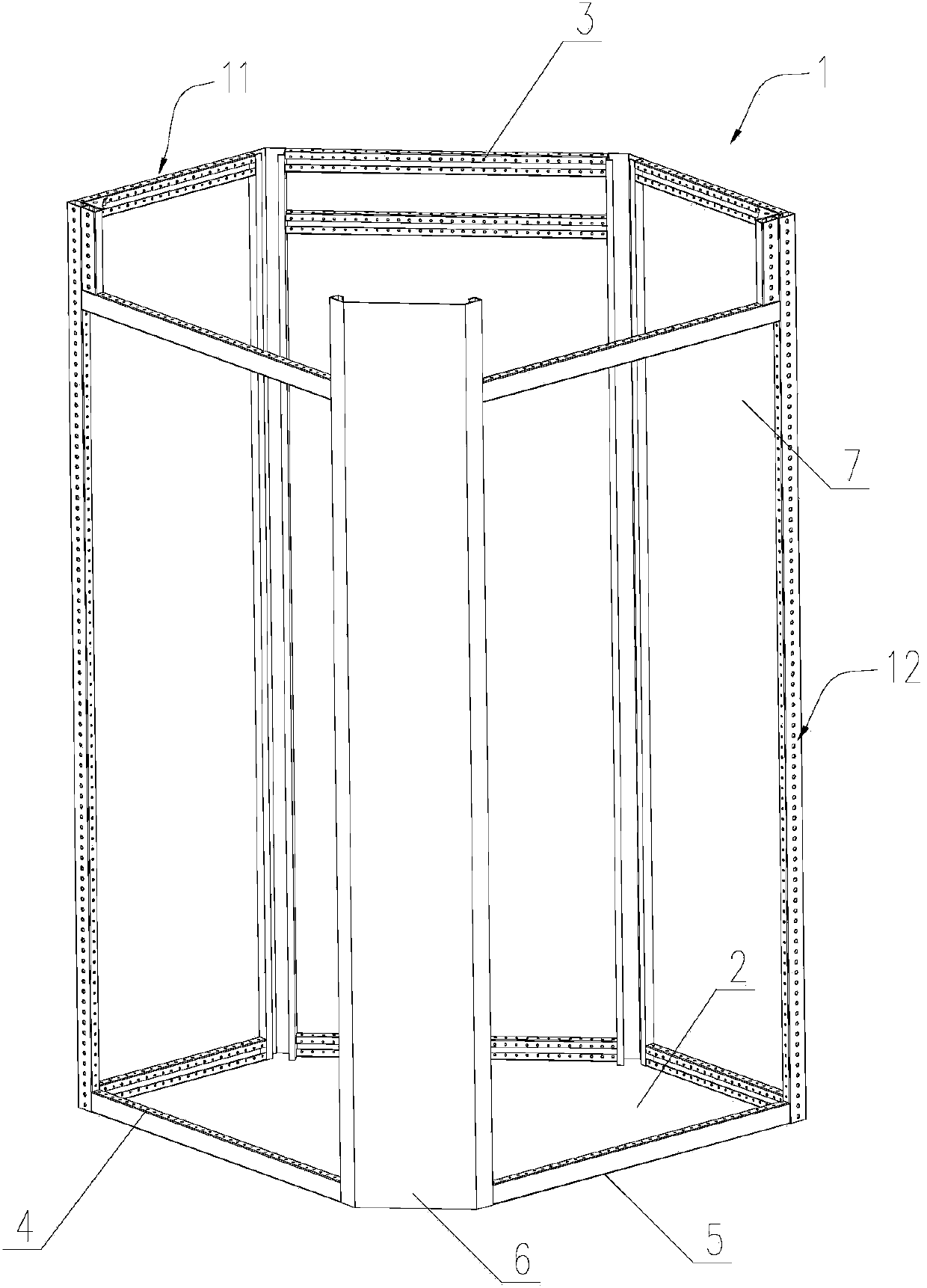

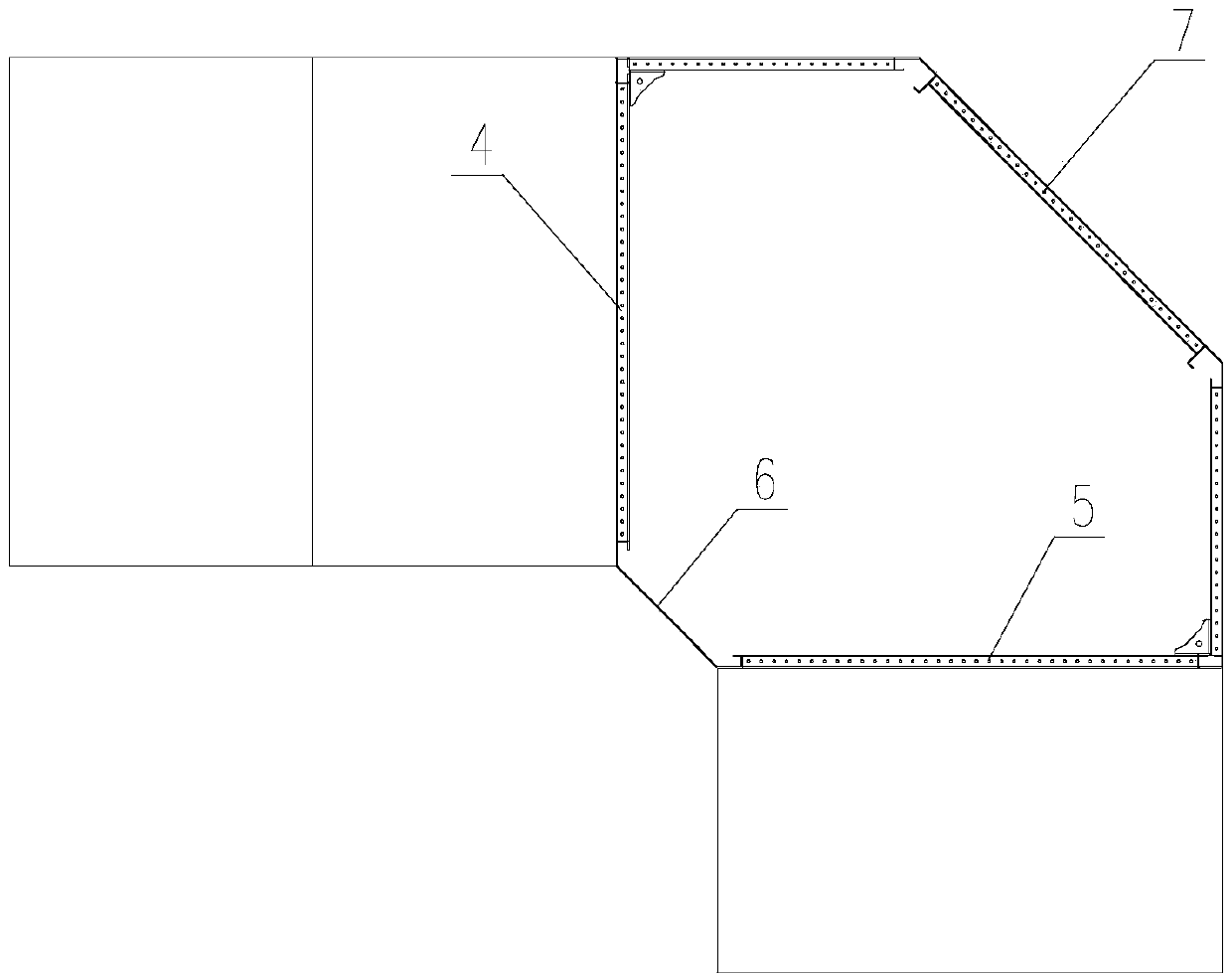

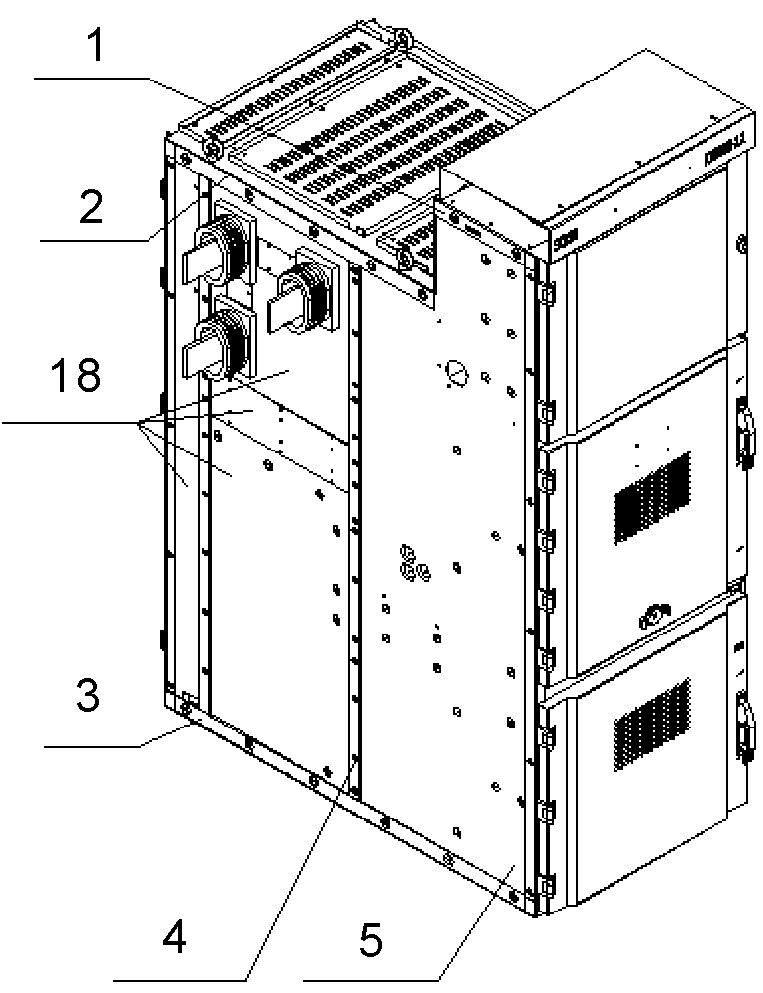

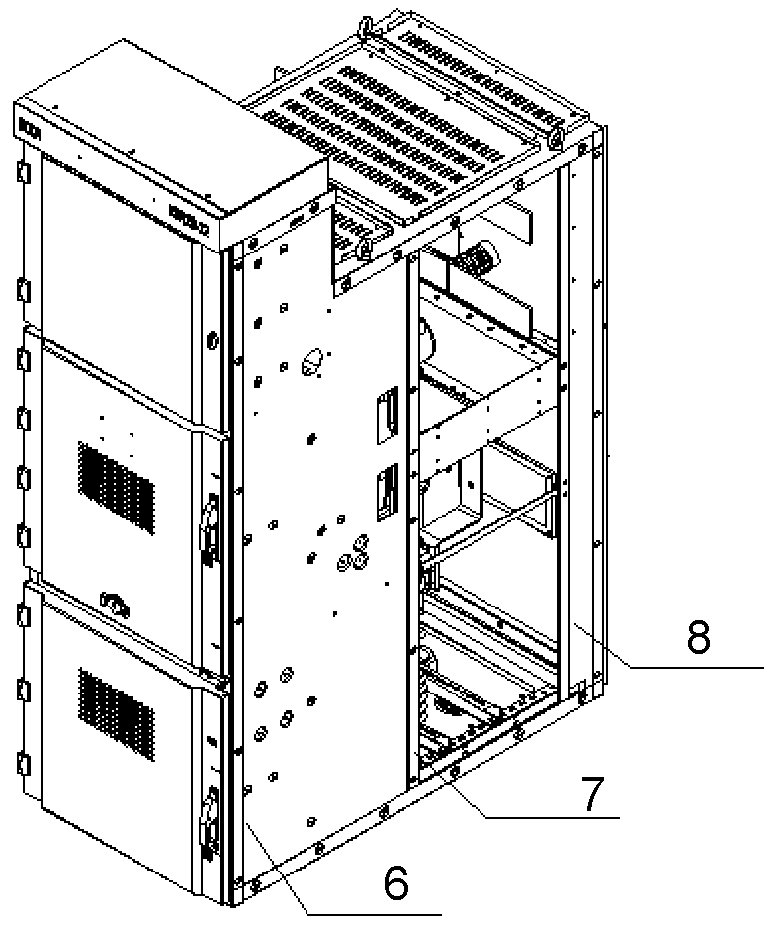

Corner cabinet

InactiveCN103812013AOvercome the disadvantage of non-adjustable angleSave boardSubstation/switching arrangement detailsEngineeringMechanical engineering

The invention relates to the technical field of electric appliance cabinets, in particular to a corner cabinet which comprises a main body frame and blanking plates. The main body frame is composed of a plurality of frame units which are in detachable connection. The corner cabinet is composed of the detachable frame units so that the shortcoming that angles cannot be adjusted once the welding cabinet is welded is overcome. In addition, processing of partial parts can be achieved in the production process of parts due to the assembly-type installation structure, and therefore the corner cabinet has the advantages of saving plates and being convenient to process. All parts of the corner cabinet can be independently sprayed by aid of the assembly-type installation structure, and accordingly spraying cannot be limited by the space of an oven. Meanwhile, the frame units can be made by galvanized plates or aluminum zinc coated plates without spraying the assembly-type installation cabinet.

Owner:KUNSHAN ZHENHONG ELECTRONICS MACHINERY

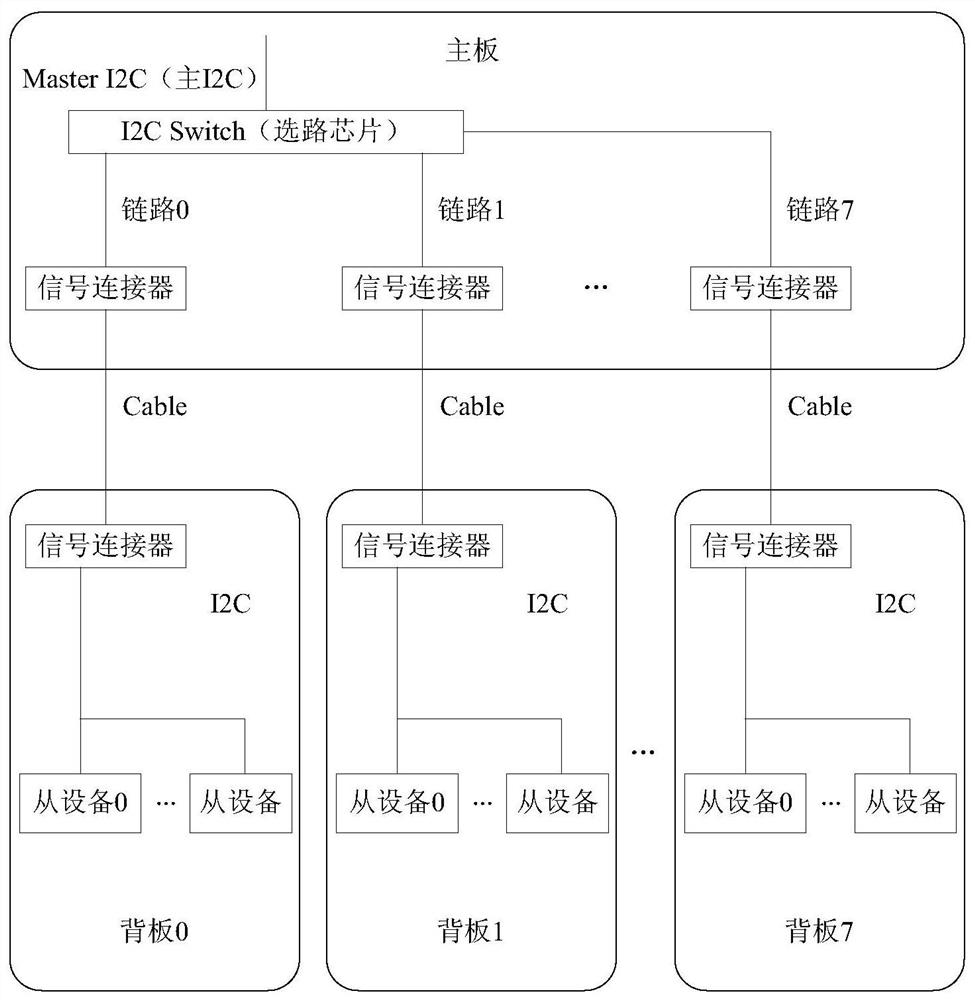

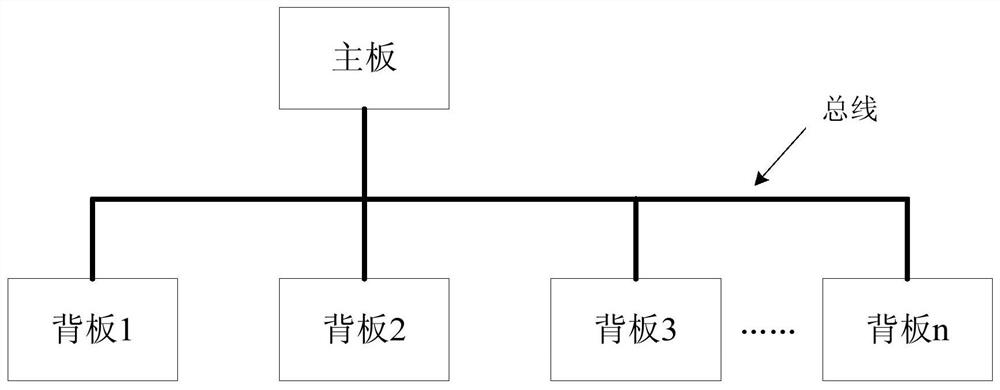

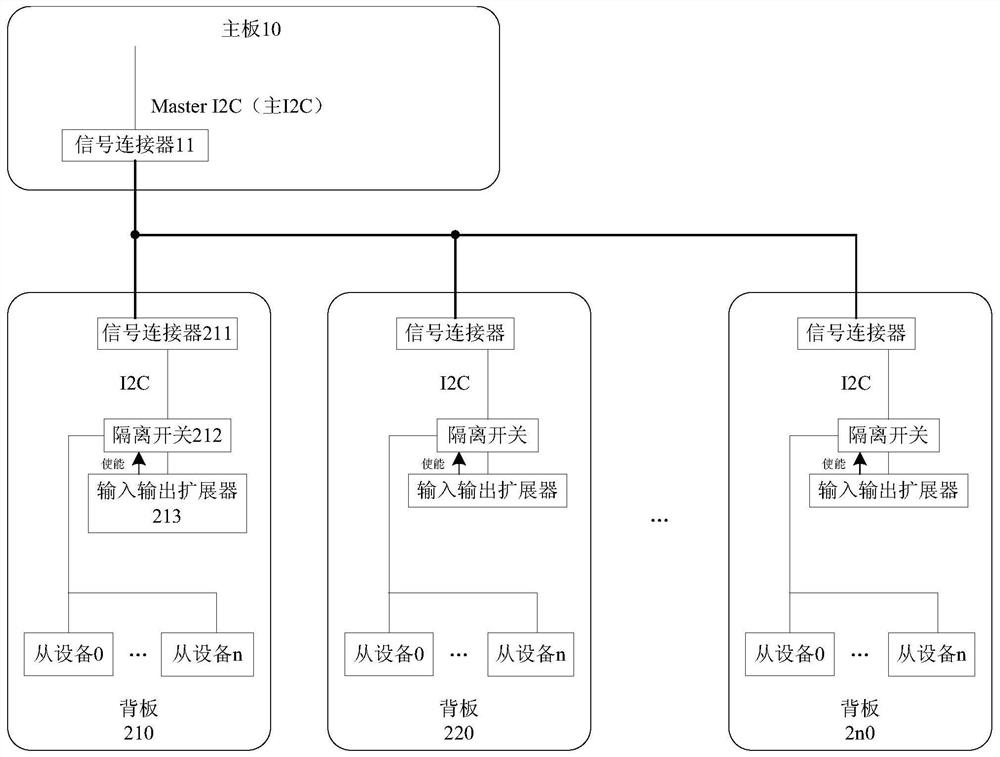

Communication system of mainboard and backboard and applicable server thereof

PendingCN112988635AFlexible choiceIncrease choice flexibilityElectric digital data processingCommunications systemEmbedded system

The invention provides a communication system of a mainboard and a backboard and a server applicable to the communication system. According to the communication system of the mainboard and the backboards, the mainboard is connected with the backboards through a bus; each backboard is provided with own preset address information; and when the main board accesses a target backboard every time, the main board accesses the target backboard through the bus according to the preset address information of the target backboard. According to the communication system of the mainboard and the backboard, the wiring space of hardware design can be saved, wiring of the hardware design is more convenient, and the wiring quality is higher.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

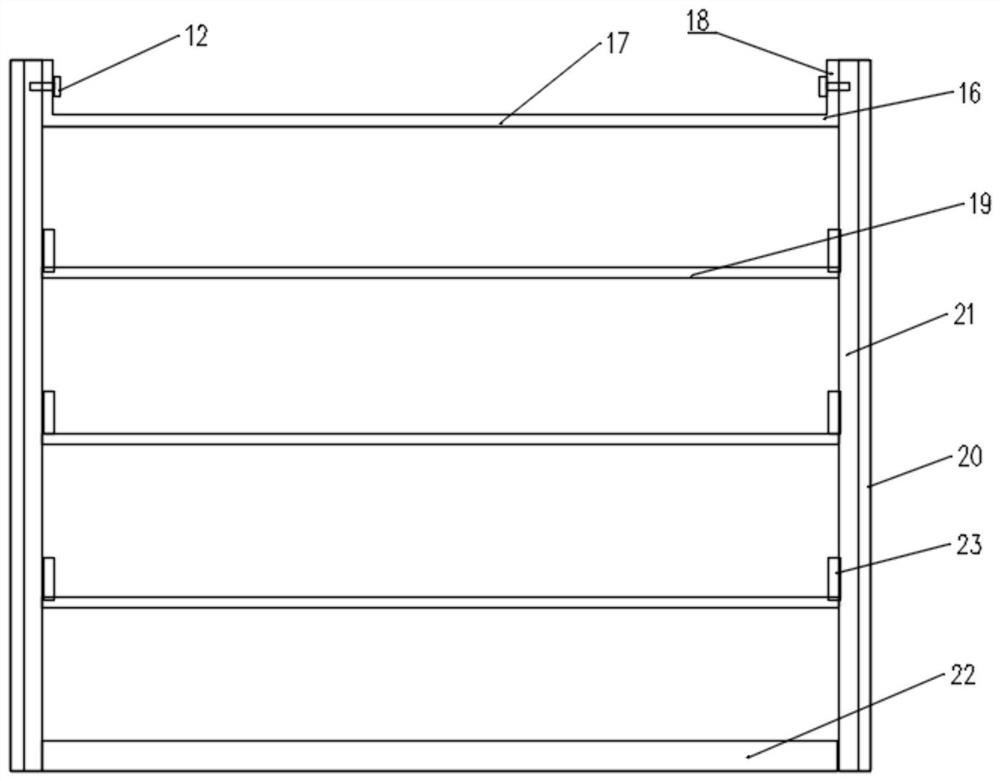

Simple and convenient installation and use of multifunctional intelligent compact shelves

ActiveCN110547604BEasy to useThe installation process is simple and convenientFurniture partsArticle advertisingStructural engineeringMechanical engineering

The invention discloses a multifunctional intelligent compact shelf which is easy to install and use. Side plate, top plate, the side plate is a combined side plate, the combined side plate includes a main body of the side plate and frame-type combined side columns arranged on opposite sides of the main body of the side plate, the top plate is a In the grooved top plate, the frame-type combined side columns include two inner and outer frame sides that are oppositely and correspondingly connected to each other through corresponding convex-concave connecting devices. The multi-functional intelligent compact rack with simple and convenient installation and use has simple and reasonable structure, simple installation process, simple, convenient and fast maintenance of the rack cabinet, and relatively high mechanical strength.

Owner:JIANGXI YUANYANG INSURANCE EQUIP IND GRP

Automobile navigation screen PCB mounting structure

InactiveCN107389073ASave materialMeet the connection requirementsInstruments for road network navigationEngineering

Owner:WUHU HONGJING ELECTRONICS

Integral riveting high-voltage switch cabinet and integral riveting method of high-voltage switch cabinet

InactiveCN110768113ASave assembly timeImprove assembly efficiencySubstation/switching arrangement casingsEngineeringStructural engineering

The invention provides an integral riveting high-voltage switch cabinet. The integral riveting high-voltage switch cabinet comprises a front top cover, a rear top cover, a bottom plate, a left mediumvertical post, a left front-side plate, a right front-side plate, a right medium vertical post, a right rear-side plate and a left rear-side plate. The integral riveting high-voltage switch cabinet has the following advantages that (1) the two processes of riveting a nut in advance and tightening a screw are reduced, thus, the assembly time is greatly reduced, and the assembly efficiency is improved; (2) a large part of a right side of a cabinet body is hollow and is not blocked by a steel plate, the part can be blocked by an adjacent cabinet body after the cabinet body is combined, and thus,the plate is conveniently saved by arranging the part to be hollow; and (3) an outer surface of a single cabinet body is even, no screw extends, an avoidance hole is unnecessary to punch in the adjacent cabinet body, the cabinet body can be pulled out in parallel only by disassembly a connected bus when the cabinet body is needed to be repaired or replaced, and the adjacent cabinet is not needed to be damaged.

Owner:四川康能电气股份有限公司

Elevator guide rail connecting structure and elevator

The invention discloses an elevator guide rail connecting structure. The elevator guide rail connecting structure is characterized in that the bottom surfaces of guide rails are perpendicular to guidesurfaces to form a T shape; a connecting plate comprises a rectangular supporting part and a main reinforcing part; the main reinforcing part is bent backwards from the first end of the supporting part, the first end is the left end or the right end, and a plurality of through holes are formed in the supporting part in the vertical direction; bolts penetrate through the through holes of the supporting part and holes in the bottom faces of two butt joint guide rails to fasten the supporting part of the connecting plate and the bottom faces of the two butt joint guide rails together; and the front side of the supporting part is attached to the bottom faces of the guide rails, and the main reinforcing part extends forwards and can intersect with the bottom faces of the guide rails. The invention further discloses an elevator using the elevator guide rail connecting structure. According to the elevator guide rail connecting structure, the thickness of a connecting plate can be reduced while the space is not occupied and front-back stress transmitted by the guide surfaces of the guide rails is effectively borne, the plate is saved, and connection between the elevator guide rails can bebetter and more economically achieved.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

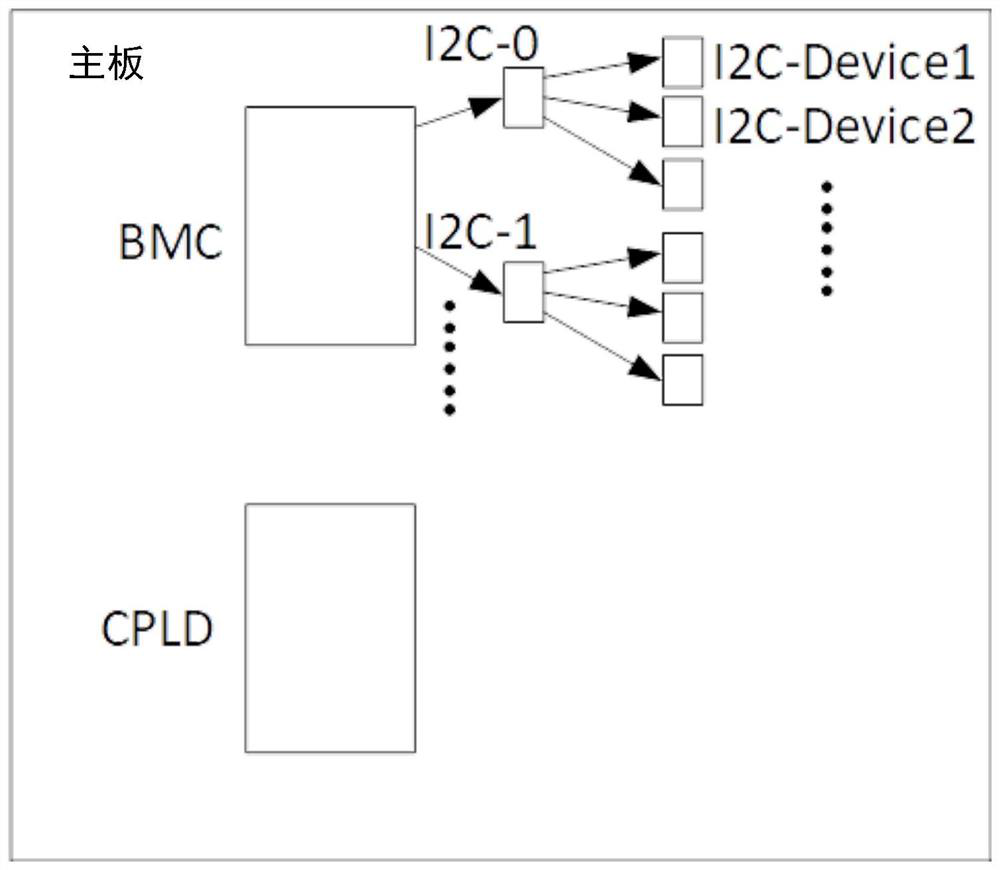

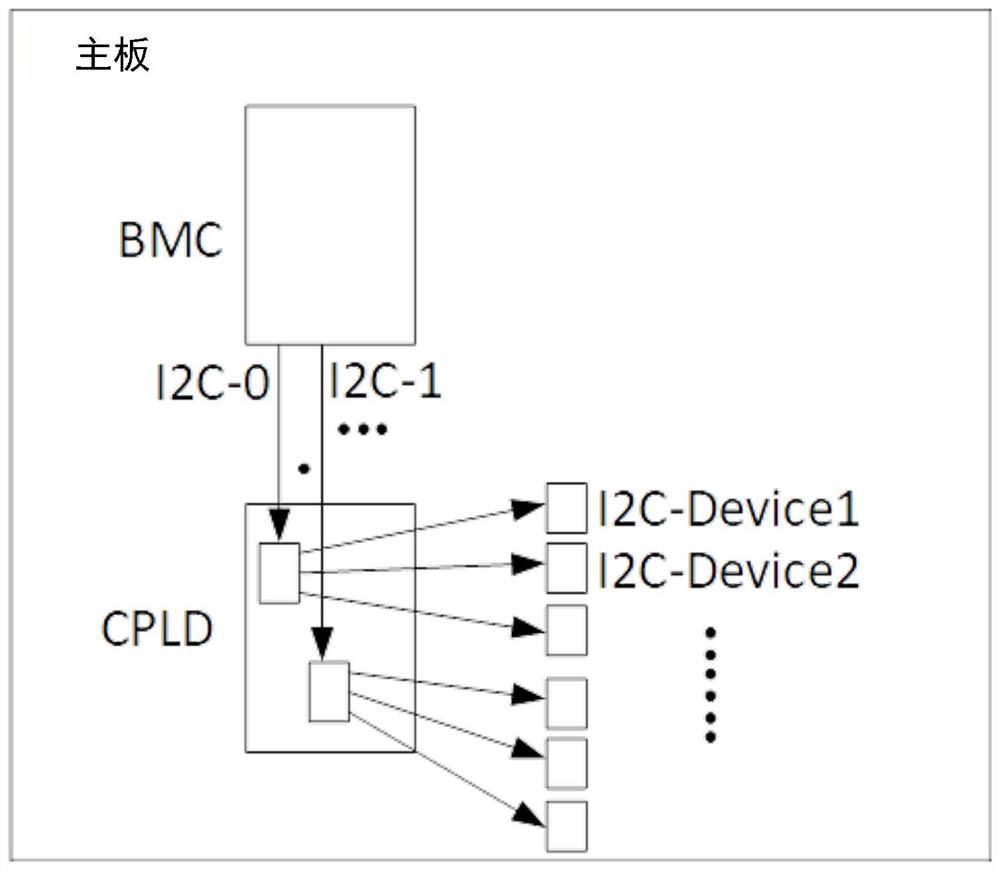

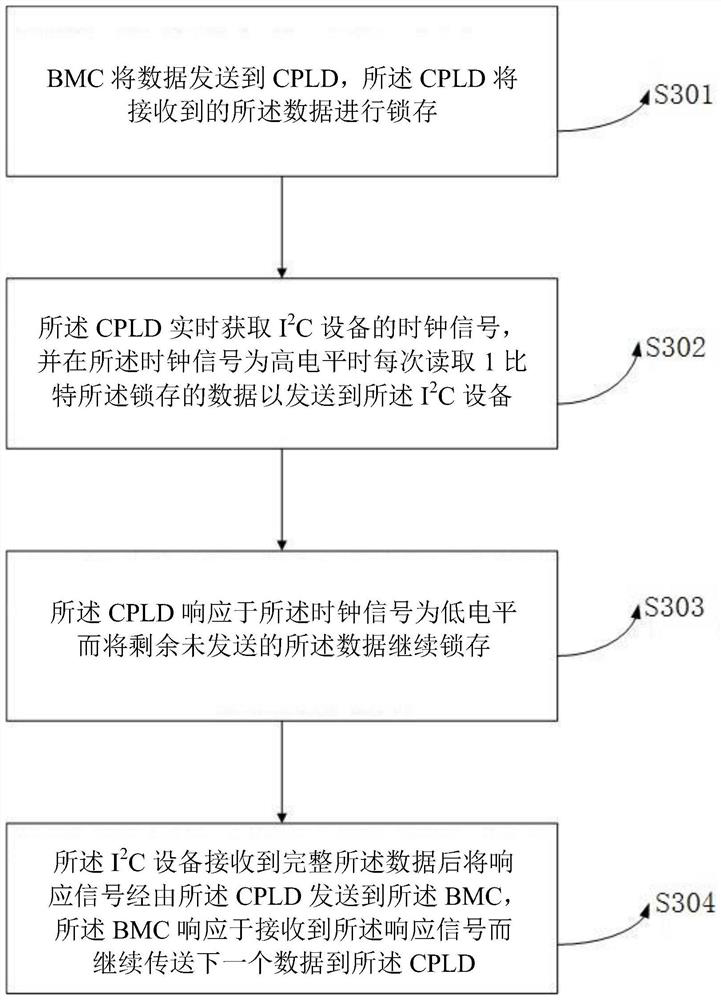

A kind of i via cpld 2 Method and device for extending c-bus

ActiveCN111339019BFunction does not affectLow costElectric digital data processingComplete dataEmbedded system

The present invention provides a kind of I through CPLD 2 A method and device for C bus expansion, the method includes the following steps: the BMC sends data to the CPLD, and the CPLD latches the received data; the CPLD acquires the I 2 The clock signal of the C device, and when the clock signal is high, the latched data is read 1 bit at a time to send to the I 2 C device; the CPLD continues to latch the remaining unsent data in response to the clock signal being low; the I 2 After receiving the complete data, the C-device sends a response signal to the BMC via the CPLD, and the BMC continues to transmit the next data to the CPLD in response to receiving the response signal. The present invention realizes I through CPLD 2 C bus extends and implements I 2 C clock stretching function, to save the board and reduce the cost of materials, and does not affect the function of the original motherboard.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

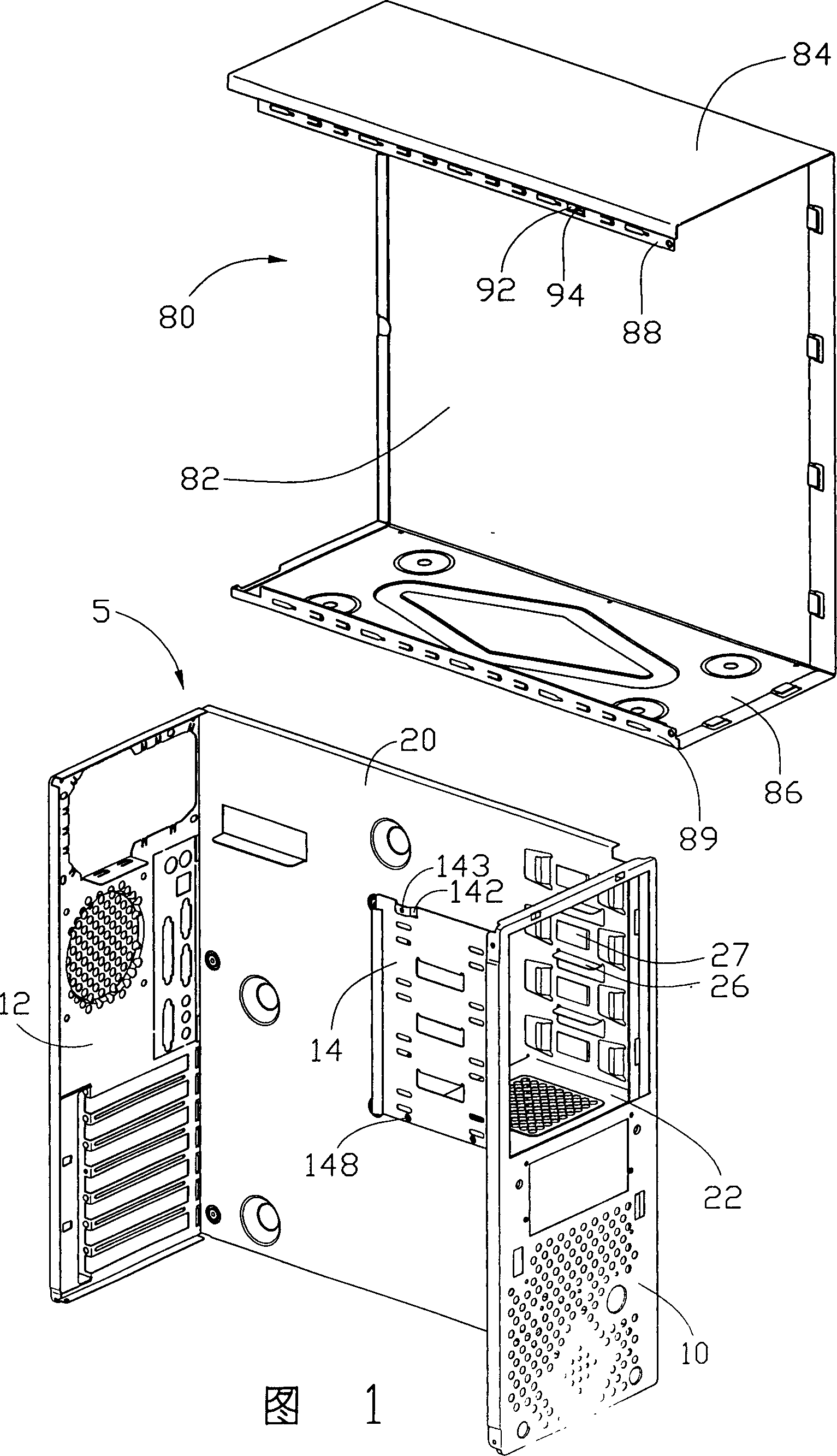

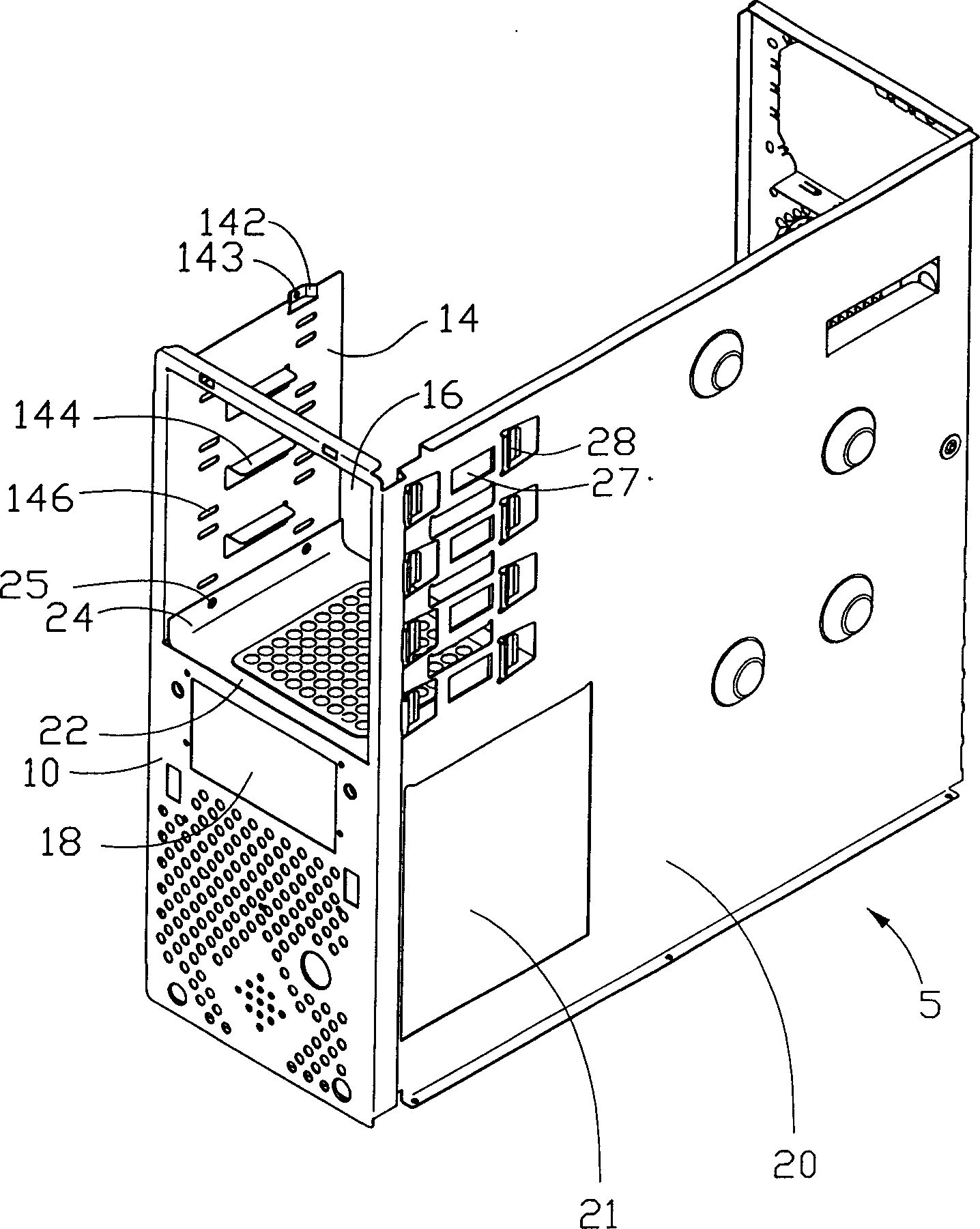

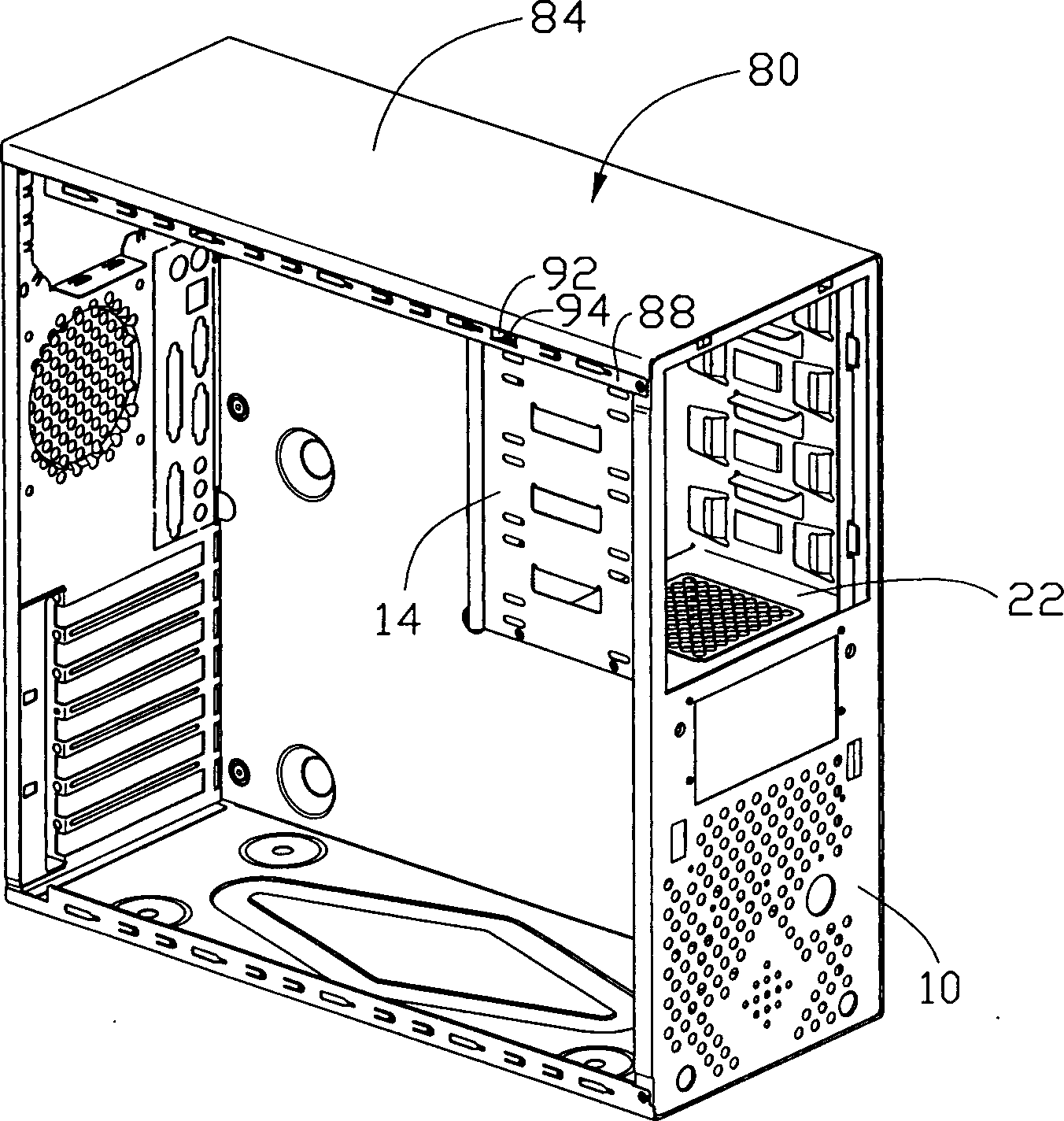

Computer casing

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

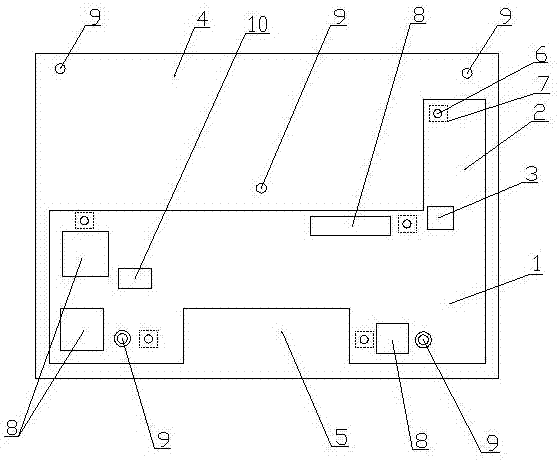

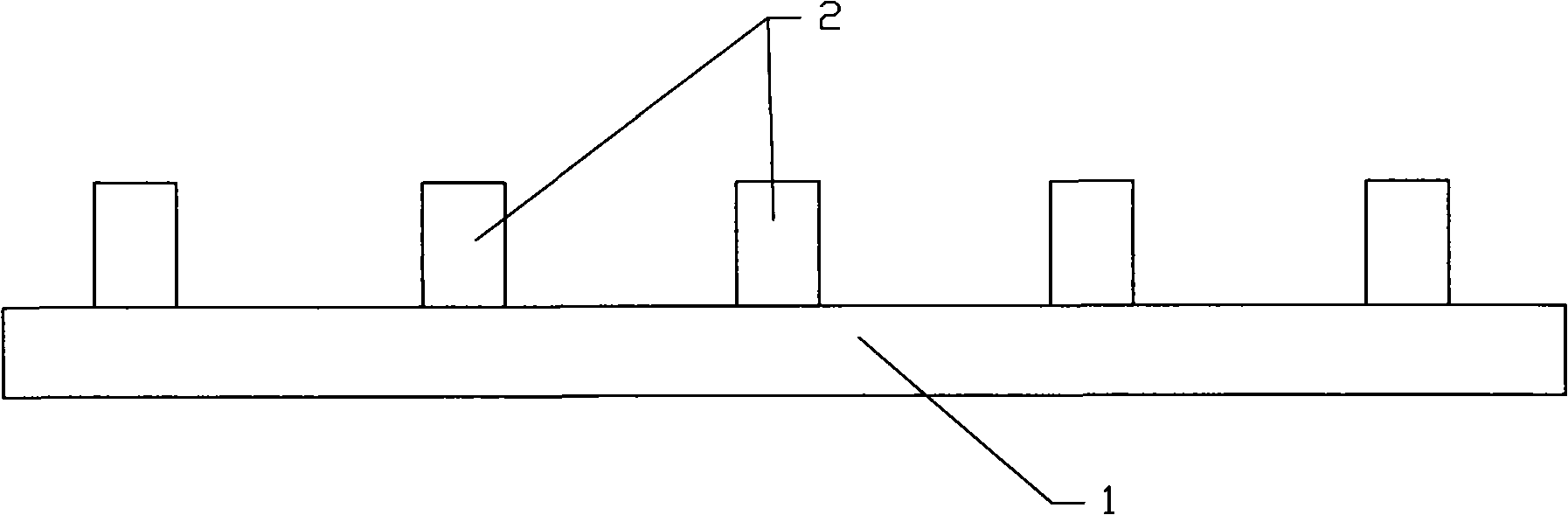

Supporting template used for sealing bottom surface of building template

ActiveCN102345380BPrevent leakageNo wasteAuxillary members of forms/shuttering/falseworksForming/stuttering elementsArchitectural engineeringCement paste

The invention discloses a supporting template used for sealing the bottom surface of a building template in a building template system. The supporting template comprises a supporting piece (1) and a connecting mechanism, wherein the supporting piece is positioned on the lower part; the connecting mechanism is molded on the upper surface of the supporting piece (1) and is spliced with the building template; the upper surface of the supporting piece (1) is suitable to be tightly bonded to the bottom surface of the building template; and a sealing mechanism for preventing the seepage of castables is arranged at the bottom of the supporting piece (1). After the supporting template used for sealing the bottom surface of the building template provided by the invention is spliced, a joint seam is tight; the integrality is high; and the seepage of cement paste can be prevented.

Owner:王亚运

Overlay decorating plate

ActiveCN102373784BSimple structureImprove waterproof and dustproof performanceCovering/liningsFlooringSurface layerButt joint

The invention discloses an overlay decorating plate, which comprises a plate body, wherein the upper surface of the plate body is a surface layer, the lower surface of the plate body is a bottom layer, at least one edge of the plate body is provided with an upward connecting part, the other edge opposite to the edge is provided with a downward connecting part, and two overlay decorating plates are mutually connected through the upward connecting part and the downward connecting part; the downward connecting part at least comprises a first inclined plane, a first tenon and a first groove; the upward connecting part at least comprises a second inclined plane, a second groove and a second tenon; and when the two overlay decorating plates are connected with each other, the first tenon is in butt joint with the second groove, the first groove is in butt joint with the second tenon, an eudipleural groove is formed between a first upper surface and a second upper surface, and the first inclined plane and the second inclined plane are in a three-dimensional butt joint state. The overlay decorating plate disclosed by the invention has a simple structure, is convenient to splice, and is material-saving.

Owner:CHANGZHOU BEMATE HOME TECH CO LTD

Integrated circuit (IC) card device fixing structure and automatic medicine selling machine provided with the same

InactiveCN103164899ASave spaceSave boardCoin-freed apparatus detailsApparatus for dispensing discrete articlesIntegrated circuitEngineering

The invention provides an integrated circuit (IC) card device fixing structure and an automatic medicine selling machine provided with the same. The IC card device fixing structure comprises a bottom board, side boards and a top board, wherein the bottom board is installed in an inclined mode, the side boards are located on two sides of the bottom board, the top board is located above the bottom board and the side boards, and a containing space is defined by the bottom board, the side boards and the top board. According to the IC card device fixing structure, the bottom board is installed in the inclined mode, so that the space occupied by the IC card device fixing structure is effectively reduced. Besides, the bottom board replaces a rear panel usually installed in an existing fixing structure simultaneously, so that the quantity of boards is reduced, and cost is lowered.

Owner:SUZHOU IRON TECH

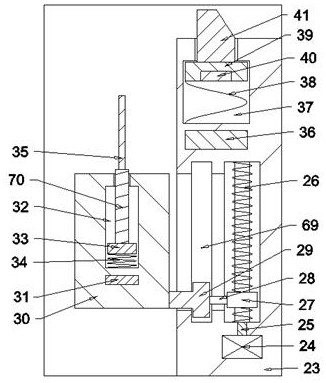

Tree plate trimming and cutting equipment

InactiveCN112497344AImprove plate utilizationSave boardFeeding devicesGripping devicesIndustrial engineeringHydraulic pressure

The invention discloses tree plate trimming and cutting equipment which comprises a base. Conveying mechanisms are arranged in the base, the two conveying mechanisms are arranged in a bilateral symmetry manner, each conveying mechanism comprises a conveying hydraulic cylinder embedded in the base, and a conveying hydraulic rod is controlled by each conveying hydraulic cylinder. Tree plates can becorrected and cut in a mechanical cooperation form, and the effects of improving the plate utilization rate and improving the correction efficiency are quite remarkable; the conveying mechanism part is arranged in the equipment, the primarily-cut plates can be conveyed and clamped, and next-step cutting is facilitated; a detection mechanism part can detect the widths of the plates, and plates arequite saved; and a cutting mechanism part can cut plates, and efficiency is high. By means of the overall design, the equipment is low in cost, simple in structure, high in automation degree and suitable for large-area popularization.

Owner:PUJIANG SULI MASCH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com