Glass window of washing machine, processing method and washing machine

A technology for washing machines and glass windows, applied in the field of observation windows, can solve the problems of low productivity of workers, many parts, complex mold structure, etc., and achieve the effects of simple structure, simplified mold structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

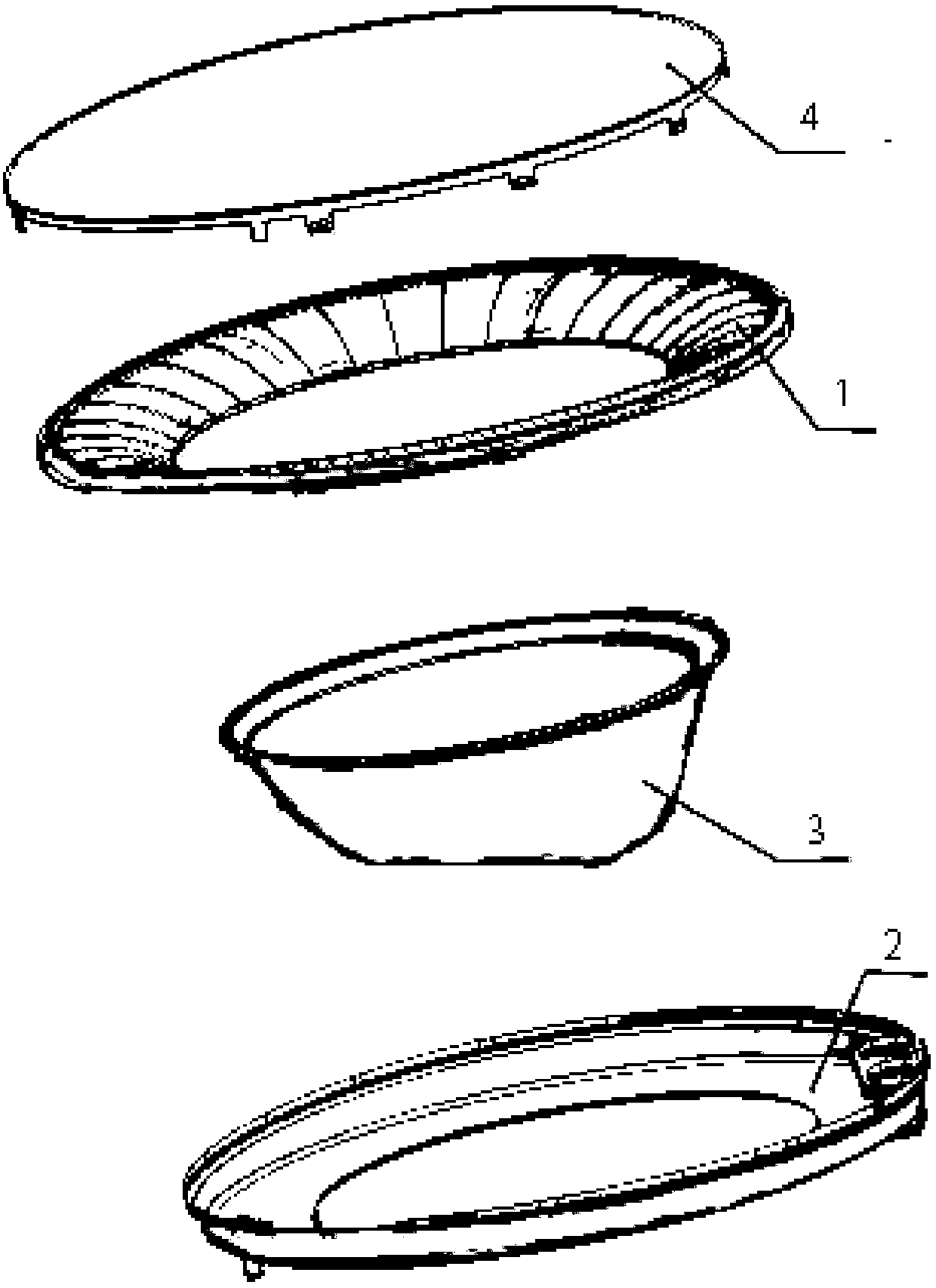

[0036] Such as figure 1 and figure 2 As shown, a glass window of a washing machine includes an outer frame 1, an inner frame 2 and an observation window glass 3.

[0037] The observation window glass 3 is arranged between the outer frame 1 and the inner frame 2, and the observation window glass 3, the outer frame 1, and the inner frame 2 are pre-installed. The foam material is injected into the space to fix the three. Through the foam fixing method, the middle frame is omitted, and no new parts are added, which reduces the cost.

[0038] The inner frame 2 is made by plate adsorption forming process. The inner frame 2 is formed by adsorption of plates, the plates are cheap, and the structure is simple, which further reduces the cost.

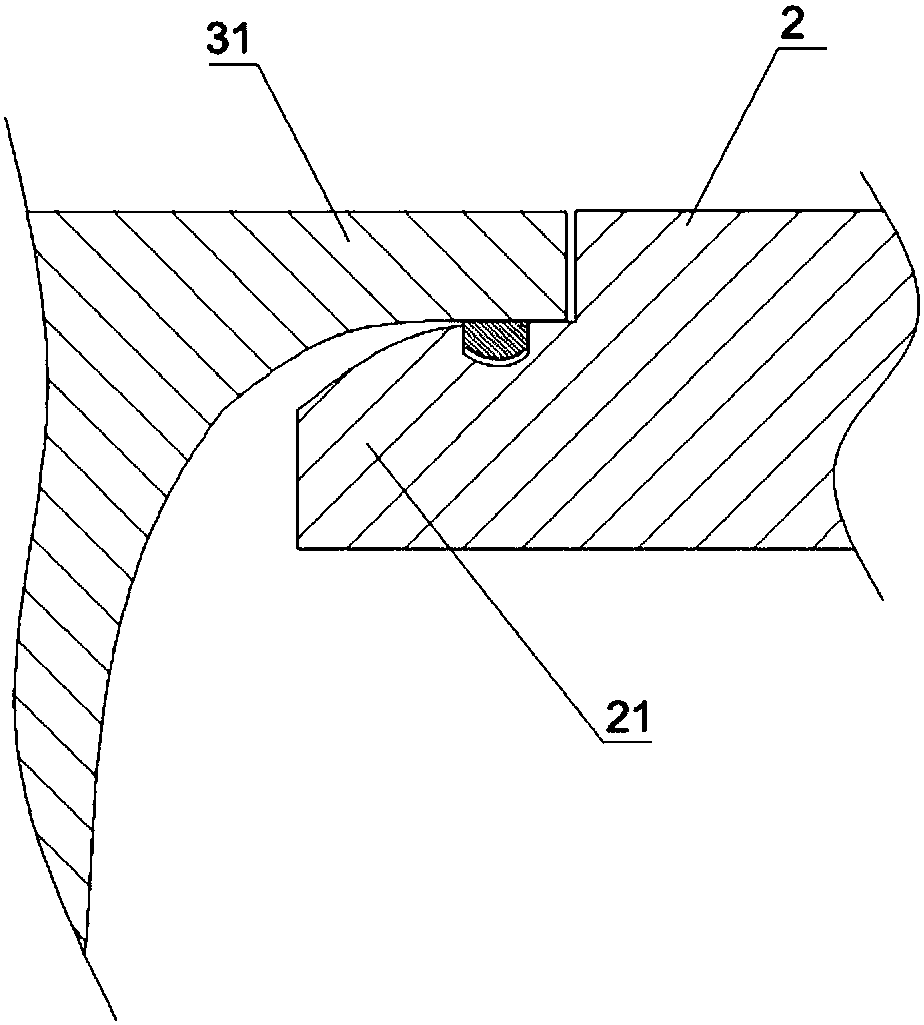

[0039] In order to realize foaming and fixing, the outer frame 1, the inner frame 2 and the observation window glass 3 need to be pre-installed, and the observation window glass 3 is provided with a first crimping edge 31, and the first crim...

Embodiment 2

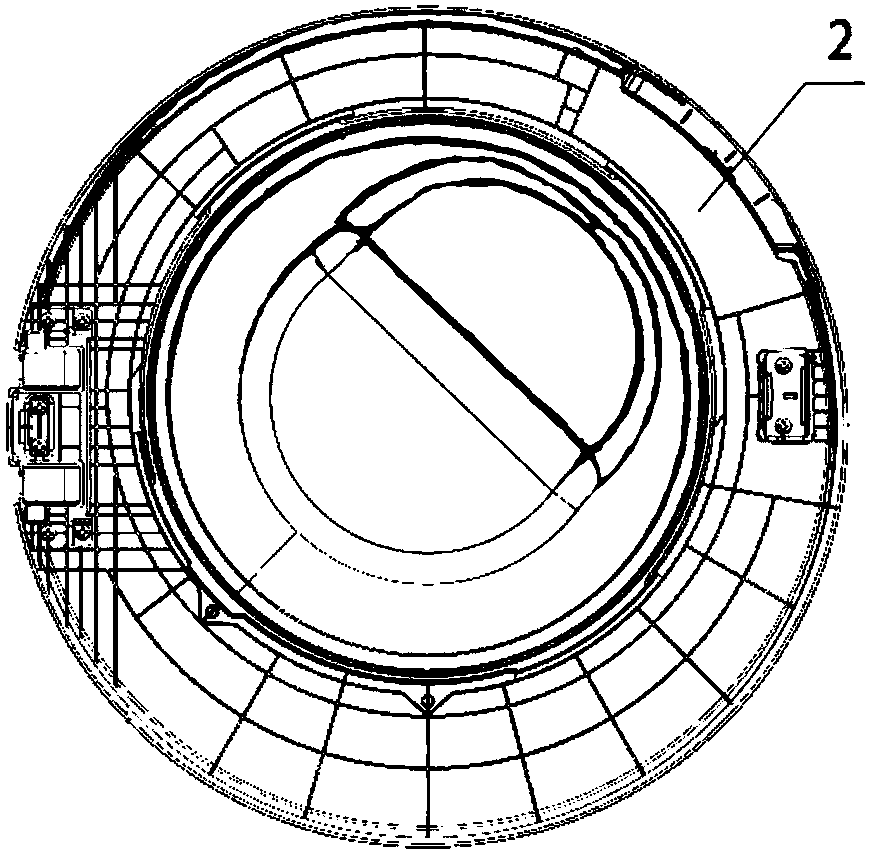

[0050] Such as Figure 3 to Figure 5 As shown, a glass window of a washing machine includes an outer frame 1, an inner frame 2 and an observation window glass 3.

[0051] The observation window glass 3 is arranged between the outer frame 1 and the inner frame 2, and the observation window glass 3, the outer frame 1, and the inner frame 2 are pre-installed. The foam material is injected into the space to fix the three. Through the foam fixing method, the middle frame is omitted, and no new parts are added, which reduces the cost.

[0052] The inner frame 2 is made by plate adsorption forming process. The inner frame 2 is formed by adsorption of plates, the plates are cheap, and the structure is simple, which further reduces the cost.

[0053] In order to realize foaming and fixing, the outer frame 1, the inner frame 2 and the observation window glass 3 need to be pre-installed. Four are set, and are used for rotating and fixing with the inner frame 2.

[0054] A first flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com