Convex point grid platform of plasma and flame numerical control cutting machine

A cutting machine and plasma technology, applied in the field of ion and flame CNC cutting machine bump grid platform, can solve the problems that parallel grids are inconvenient for operators to walk safely, affect cutting accuracy, cut plane grids and other problems, and achieve the elimination of safety Hidden dangers, health protection, and the effect of operation and walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

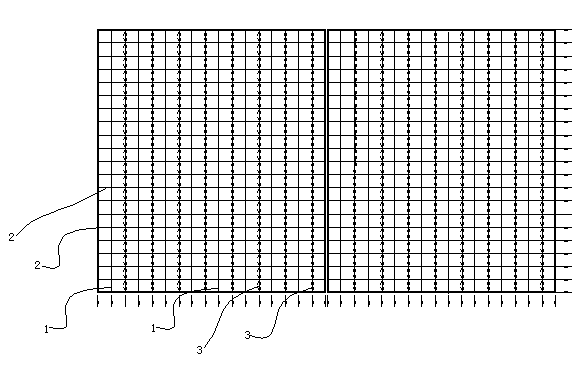

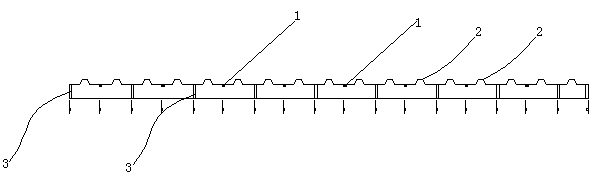

[0021] refer to figure 1 and figure 2 As shown in the present invention, a plasma and flame CNC cutting machine bump grid platform includes a square steel plate 1, a bump plate 2 and a longitudinal rib plate 3.

[0022] The square steel plate 1 and the longitudinal rib plate 3 are arranged longitudinally at intervals, while the bump plate 2 is arranged horizontally. The bump plate 2 can be formed by cutting flat steel with bumps by numerical control to form a double-layer grid structure.

[0023] The bump plate 2 is preferably arranged in parallel. The parallel bumps reduce the contact surface between the bumps and the steel plate, reduce frictional resistance, accelerate the tension separation of the steel plate cutting gap to eliminate adhesion, and achieve better cutting quality.

[0024] A mounting groove for a square steel plate 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com